Prefabricated inner support edge node structure of foundation pit and construction method

A node structure and assembly technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of manpower and material resources, non-compliance, difficulty, etc., to facilitate recycling, ensure detachability, and ensure the safety of foundation pits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

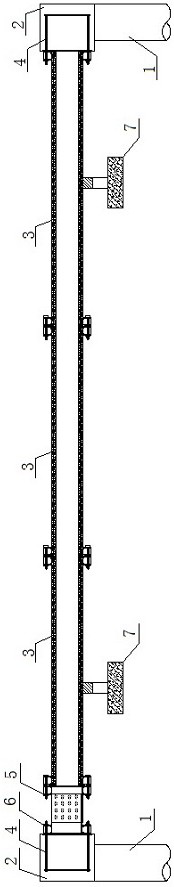

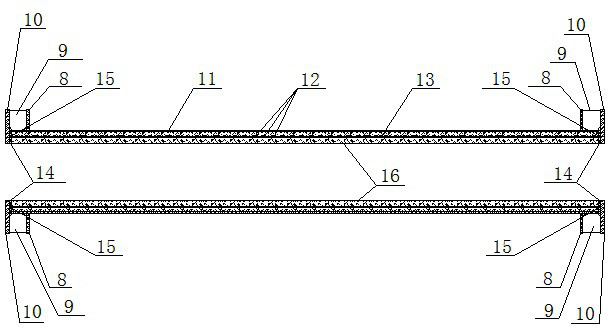

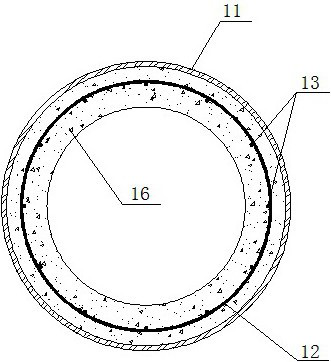

[0051] Such as Figure 11-Figure 14 As shown, the present embodiment provides a supporting side node structure in an assembled foundation pit, including an assembled support and a crown beam 2 or a waist beam; the end of the assembled support is fixed with a first expansion joint 5, and the crown beam 2 or the inner side of the waist beam is fixed with a second expansion joint 6; the structure of the first expansion joint 5 and the second expansion joint 6 are the same, including a solid steel plate 20, a U-hole steel plate 21, and a U-shaped steel plate 22 and a stiffening plate 32; one end of the U-shaped steel plate 22 runs through the U-shaped hole on the U-shaped steel plate 21 and is welded with the solid steel plate 20, and the two side walls of the other end are provided with multiple rows of oblong holes 23; The solid steel plate 20 is connected to the U-shaped steel plate 21 through a stiffening plate 32, and the side wall of the U-shaped steel plate 22 is welded to ...

Embodiment 2

[0066] This embodiment provides a construction method for the supporting edge node structure in the prefabricated foundation pit provided by Embodiment 1, which includes the following steps:

[0067] S1. According to the design drawings, the prefabricated support segment 3, the embedded parts 4, the first expansion joint 5 and the second expansion joint 6 are produced in the factory, and transported to the construction site;

[0068] S2. Splicing and assembling the prefabricated support segment 3 section by section through the screw rod 17 and the nut 18 to form an assembled support; and connecting the first expansion joint 5 to the prefabricated support segment 3 at the end through the screw rod 17 and the nut 18;

[0069] S3, placing the embedded part 4 at the support design position in the crown beam 2 or the waist beam to be poured, and then pouring the crown beam 2 or the waist beam, so that the embedded part 4 is embedded therein;

[0070] S4. After the crown beam 2 or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com