Method and device for producing high aromatic content gasoline by upgrading Mtp by-product mixed aromatics, high aromatic content gasoline and application thereof

A technology of mixed aromatics and high aromatics, applied in the field of aromatics chemical industry, can solve the problems of unable to quickly increase aromatics content, unstable aromatics content, high investment cost of equipment, etc., achieve the effect of reducing aromatics content, increasing olefin content, and reducing production cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

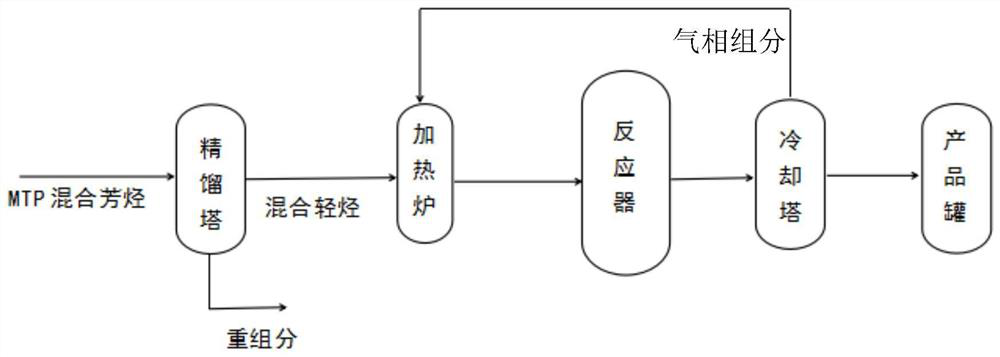

[0049] According to a preferred embodiment of the present invention, the device for upgrading the MTP by-product mixed aromatics to produce gasoline with high aromatics content is as follows: figure 1 As shown, the device includes: a rectifying tower, a heating furnace, a fixed-bed reactor, a cooling tower and a product tank that are communicated in sequence; the rectifying tower is used to rectify the mixed aromatics produced by MTP to obtain the heavy components and Mixed light hydrocarbons with distillation range <165°C; the heating furnace is used for heating the mixed light hydrocarbons to obtain heated mixed light hydrocarbons; the fixed bed reactor is used for mixing the heated mixed light hydrocarbons with The aromatization catalyst is contacted to perform an aromatization reaction to obtain an aromatized product; the cooling tower is used to cool the aromatized product to obtain gas phase components and gasoline with high aromatic content; the product tank is used for ...

Embodiment 1

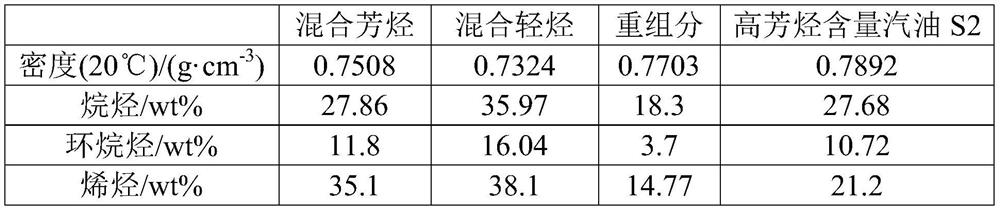

[0056] (1) carry out rectification of MTP by-product mixed aromatics in a rectifying tower to obtain mixed light hydrocarbons and heavy components with a distillation range of <165 ° C, wherein, the theoretical plate number of the rectifying tower is 15, and the conditions of rectification Including: the reflux ratio is 5:1, the extraction rate is 15mL / min, and the heating rate is 0.5℃ / min;

[0057] (2) adjusting the space velocity of the mixed light hydrocarbons obtained in step (1) to be 1h -1 , and pressurized 1.5MPa by the feed pump and transported to a 350 ℃ heating furnace for heating, and then entered a fixed bed reactor equipped with ZSM-5 strip catalyst for aromatization reaction to obtain aromatization products; wherein, The conditions of the aromatization reaction include: the temperature of the catalyst bed is 450°C, and the temperature of the column core is 460°C;

[0058] (3) the aromatization product obtained in step (2) is cooled in a cooler to obtain high aro...

Embodiment 2

[0063] (1) carry out rectification of MTP by-product mixed aromatics in a rectifying tower to obtain mixed light hydrocarbons and heavy components with a distillation range <165 ° C, wherein, the theoretical plate number of the rectifying tower is 30, and the conditions of the rectifying Including: the reflux ratio is 8:1, the extraction rate is 25mL / min, and the heating rate is 0.5℃ / min;

[0064] (2) adjusting the space velocity of the mixed light hydrocarbons obtained in step (1) to be 1h -1 , and pressurized 1.5MPa by the feed pump and transported to a 300 ℃ heating furnace for heating, and then entered a fixed bed reactor equipped with ZSM-5 strip catalyst for aromatization reaction to obtain aromatization products; wherein, The conditions of the aromatization reaction include: the temperature of the catalyst bed is 350°C, and the temperature of the column core is 360°C;

[0065] (3) the aromatization product obtained in step (2) is cooled in a cooler to obtain high aroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com