Preparation method of corrosion-resistant and friction-resistant holographic laser hot stamping film

A laser hot stamping film, anti-friction technology, applied in the direction of film/sheet adhesive, temperature recording method, film/sheet release coating, etc., can solve the problem of poor wear resistance and corrosion resistance of laser hot stamping film problem, to achieve the effect of brightness and anti-counterfeiting strength guarantee, long service life and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

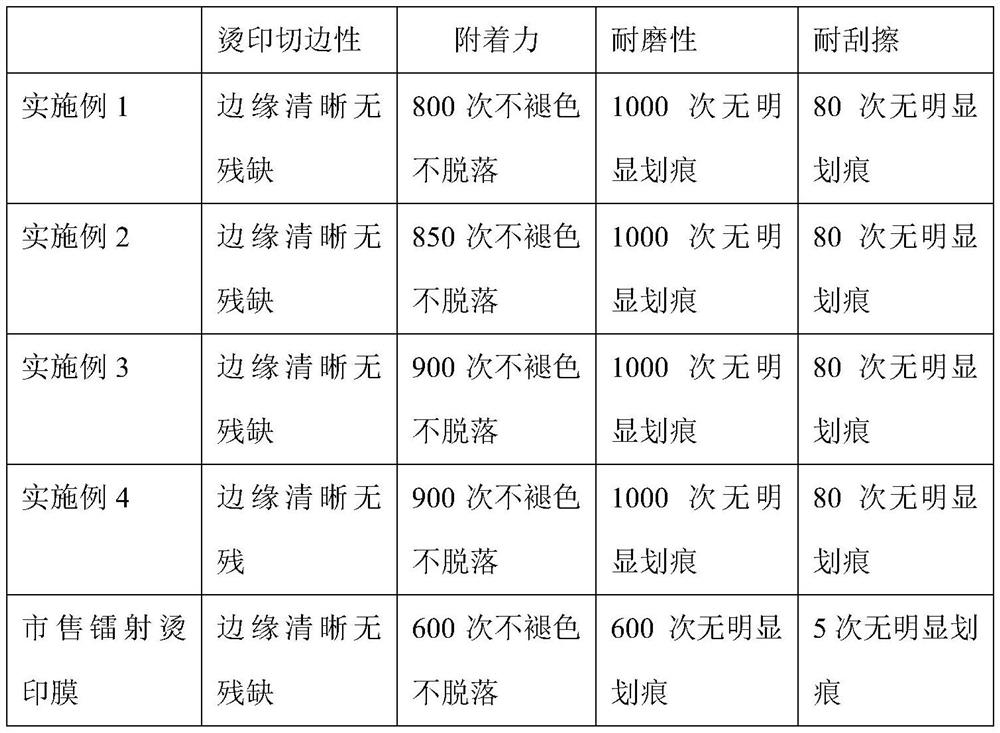

Examples

Embodiment 1

[0034] Embodiment 1: A method for preparing a corrosion-resistant and friction-resistant holographic laser hot stamping film, which includes, from bottom to top, a base layer, a peeling layer, a color layer, an electroplating layer, and a glue layer; calculated in parts by weight, the base layer includes The following components are: 50-70 parts of modified acrylic resin, 30-40 parts of polyurethane film and 5-13 parts of covalent organic framework material.

[0035] Its preparation method comprises the following steps:

[0036] Including the following steps:

[0037] S1. After mixing 50-70 parts of modified acrylic resin, 30-40 parts of polyurethane film and 5-13 parts of covalent organic framework material, pultrusion is formed into a film to form a base layer, and rolled on the unwinding reel of the coating machine On, the release agent is poured into the coating tank of the coater, and then the coater is turned on to coat the release agent on the base layer, and the base ...

Embodiment 2

[0044] Embodiment 2: A method for preparing a corrosion-resistant and friction-resistant holographic laser hot stamping film, which includes, from bottom to top, a base layer, a peeling layer, a color layer, an electroplating layer, and a glue layer; calculated in parts by weight, the base layer includes The following components: 70 parts of modified acrylic resin, 40 parts of polyurethane film and 13 parts of covalent organic framework material.

[0045] Its preparation method comprises the following steps:

[0046] Including the following steps:

[0047] S1. Mix 70 parts of modified acrylic resin, 40 parts of polyurethane film and 13 parts of covalent organic framework material, and then pultrude the film to form the base layer, and roll it on the unwinding shaft of the coating machine. 30 parts and Mg 5 Si 20 (OH) 2 (OH 2 ) 4 4H 2 8 parts of O crystal material, the solvent is 10-15 parts of ethanol and 20-25 parts of water in the coating tank of the coating machine, ...

Embodiment 3

[0054] Embodiment 3: A method for preparing a corrosion-resistant and friction-resistant holographic laser hot stamping film, which includes, from bottom to top, a base layer, a peeling layer, a color layer, an electroplating layer, and a glue layer; calculated in parts by weight, the base layer includes The following components: 50 parts of modified acrylic resin, 30 parts of polyurethane film and 5 parts of covalent organic framework material.

[0055] Its preparation method comprises the following steps:

[0056] Including the following steps:

[0057] S1. After mixing 50 parts of modified acrylic resin, 30 parts of polyurethane film and 5 parts of covalent organic framework material, the film is pultruded to form the base layer, and rolled on the unwinding shaft of the coating machine, and the water-based release 30 parts and Mg 5 Si 20 (OH) 2 (OH 2 ) 4 4H 2 8 parts of O crystal material, solvent is that 10 parts of ethanol and 20 parts of water enter in the coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com