Odor self-purification multilayer tower type aerobic composting reactor

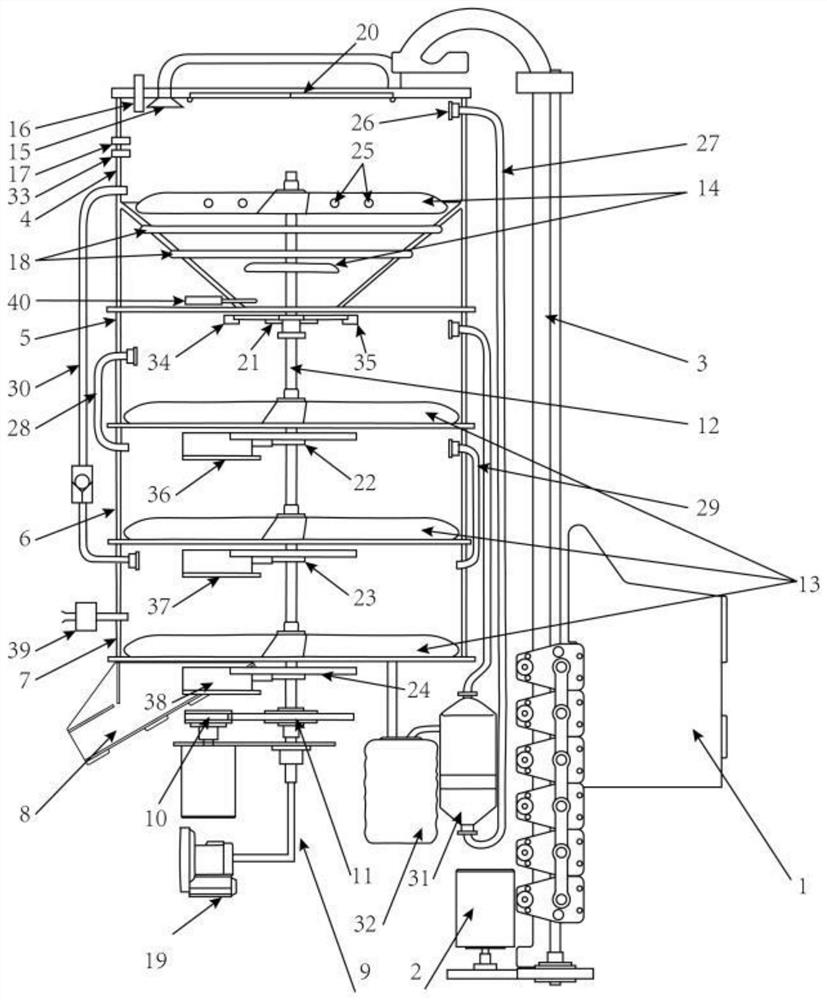

An aerobic composting and reactor technology, which is applied in the application, organic fertilizer, fertilization device and other directions, can solve the problems such as the overall occupation of the process, the increase in the production cost of organic fertilizer, and the emission of ammonia-containing odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The above-mentioned device is used to carry out aerobic composting treatment on the fungus residue. Mix the fungus residue, sawdust and fungus chaff according to the wet weight ratio of 4:4:2, and add the compound bacterial agent (dosing amount is 0.5% of the dry weight of the mixed material), to obtain a C / N ratio of 20:1~30: 1 of the compost material and pour it into the feed bin, the composting time is 48 days.

[0027] The above-mentioned device has 4 layers in total. The ratio of the headspace volume of the high-temperature fermentation bin layer, that is, the tank body 4 of the first layer, to the total headspace volume of the decomposing deodorization bin layer, that is, the second, third, and fourth layers, is 1:4. The feed box 1 lifts the stacked material along the lifting slide rail 3 and pours it into the first layer of tank body 4 . According to the moisture content information collected by the humidity sensor 17, the central control system adjusts the mois...

Embodiment 2

[0032] The odor self-purifying multi-layer tower type aerobic composting reactor is applied to the treatment of food waste. Food waste and fillers are put into the feeding box, and the stepping motor drives the feeding box along the sliding rail to pass the material through the feeding box. The material door is poured into the first layer of tanks for high-temperature fermentation. At the same time, the second, third, and fourth layers of tanks are filled with materials in the decomposing stage. In the first layer of tanks, when the oxygen sensor shows that the concentration is 10-15%, stop the aeration; Aeration; when the concentration reaches 15%, stop the aeration, and at this time the gas in the fourth layer tank will be discharged from the fourth layer exhaust port.

[0033] The heating belt in the first tank body maintains the material at 55°C to 65°C for more than 5 days. When the temperature sensor shows that the temperature drops below 55°C, turn on the heating belt ...

Embodiment 3

[0039] This embodiment is a further improvement of Example 2, the main improvements are:

[0040] (1) In embodiment 2, an oxygen sensor and an aeration system can be installed in the tank body of the fourth layer to detect the oxygen concentration. gas effect.

[0041] (2) In embodiment 2, in order to ensure that the odor is fully reacted in the circulation, fans can be installed in each pipeline to increase the gas circulation speed. The four to one layer pipelines are canceled, the four to two layer pipelines are set, and the exhaust branches are arranged in the four to two layer pipelines. When the first floor is not aerated, the first to second floor pipelines are closed, the fourth to second floor pipelines lead to the second floor, and the gas circulates between the second, third and fourth floors. When the first layer is aerated, the first to second layer pipes are opened, and the fourth to second layer pipes discharge the gas, so that the original fourth layer of gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com