Multistage automatic deviation rectifying device for coal conveying belt of thermal power plant

An automatic rectification device, a technology for thermal power plants, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of not getting the ideal rectification effect, expensive equipment, and not very good application effect of rectification equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

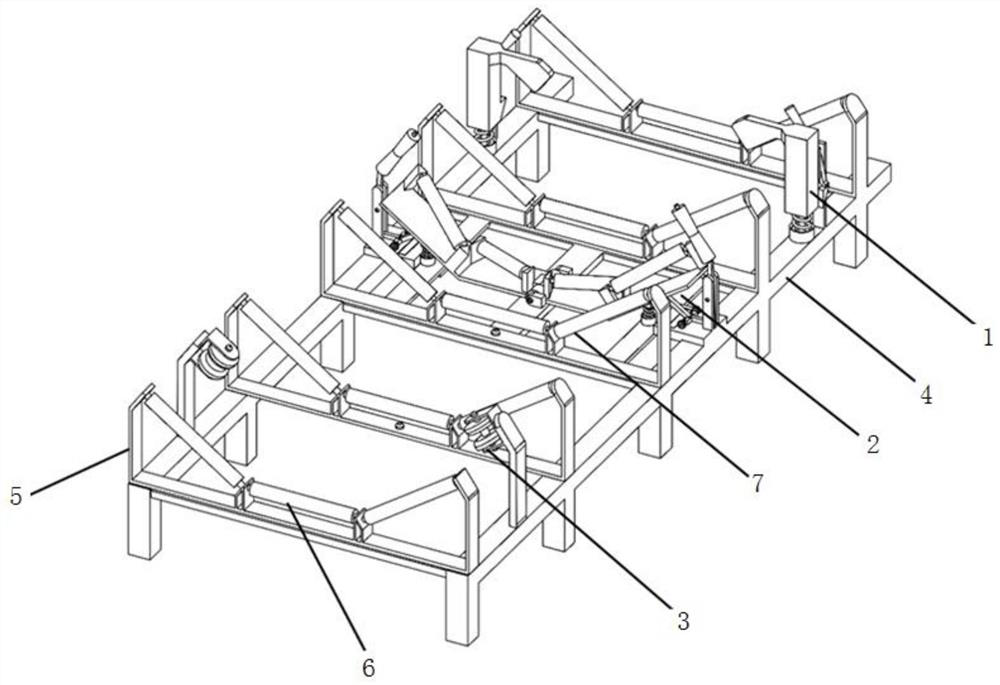

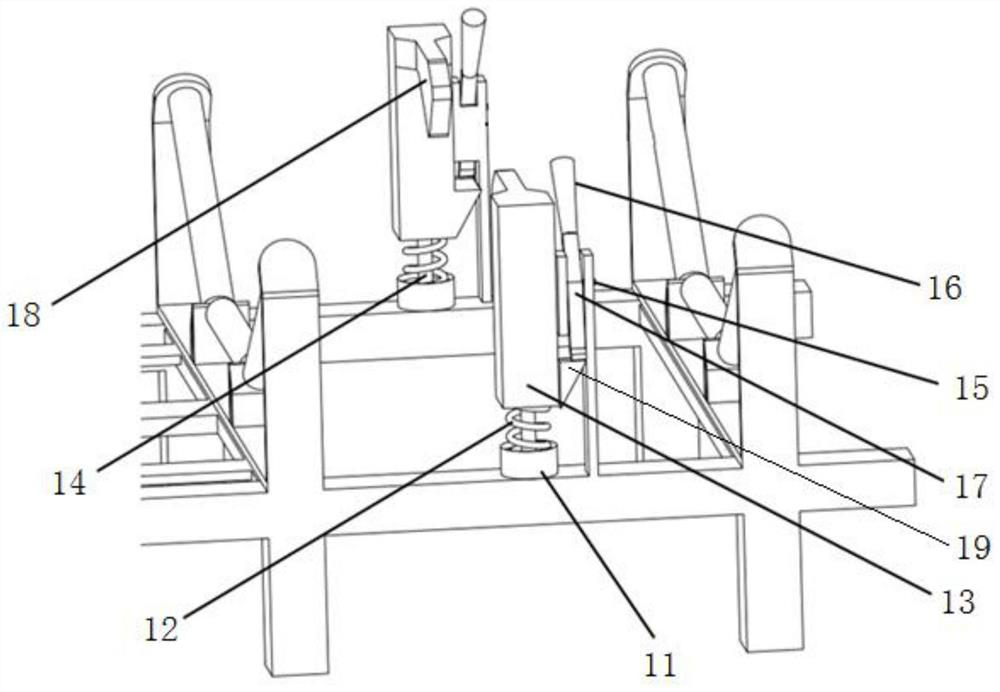

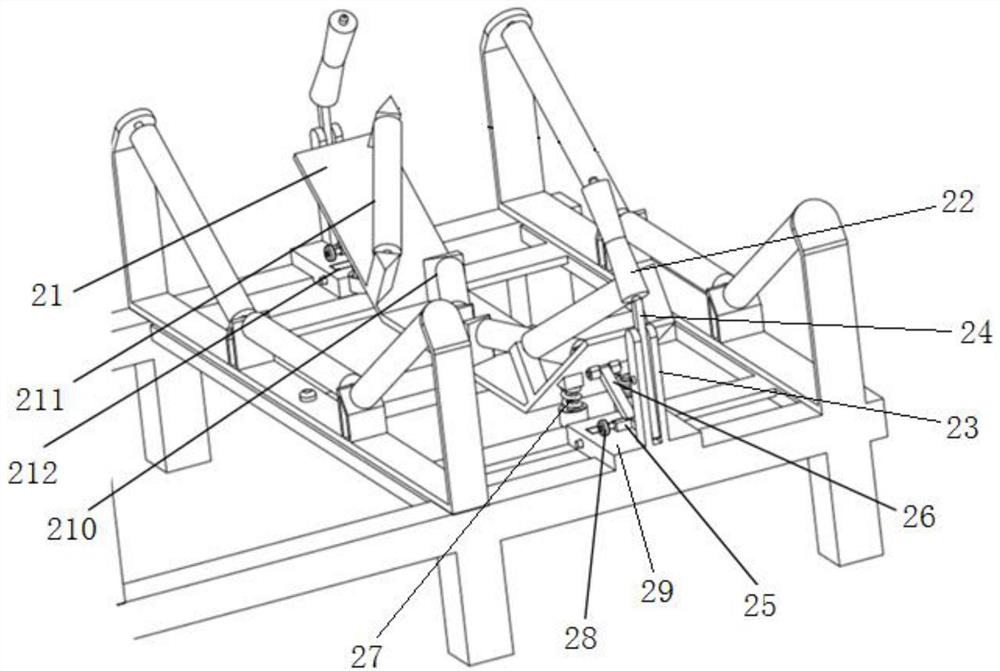

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a multi-stage automatic deviation correction device for a thermal power plant coal conveying belt provided in an embodiment of the present invention, such as figure 1 , Figure 6 As shown, the device includes a coal-scraping deviation correction mechanism 1, a flipping deviation correction mechanism 2, and a forced deviation correction mechanism 3 arranged in sequence along the running direction of the belt 8; Multi-stage automatic deviation correction of the belt.

[0037] The coal scraping correction mechanism 1 is used to correct the deviation of the belt due to the incorrect coal drop point; specifically, as figure 2As shown, the coal scraping and deviation correction mechanism 1 includes two sets of coal scraping assemblies formed on both sides of the belt 8 and arranged oppositely on the frame 4 . The coal scraping assembly includes a spring base 11, a spring 12, a slide table 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com