Abnormal-sound-proof high-temperature-resistant mechanical bushing

A high-temperature, mechanical technology, applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of increased vehicle noise, increased friction coefficient, abnormal friction noise, etc. The effect of tension force, reduction of deformation, and increase of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

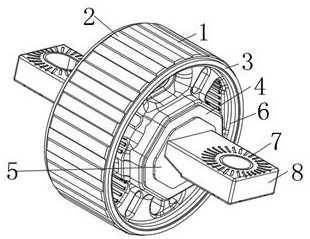

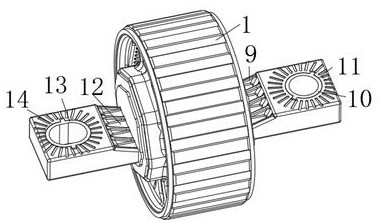

[0041] Example: Reference Figure 1-8 The shown anti-abnormal noise and high temperature resistant mechanical bushing includes a first outer sleeve 1, which may be a metal pipe body in the prior art.

[0042] A second outer sleeve 3 is fixedly connected inside the first outer sleeve 1, and the second outer sleeve 3 may be a metal pipe body in the prior art.

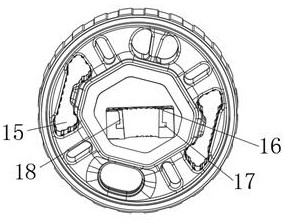

[0043] The second outer sleeve 3 is fixedly connected with a rubber sleeve 6, and the rubber sleeve 6 is fixedly connected with an inner sleeve 4. The inner sleeve 4 can be a metal pipe body in the prior art, and the rubber sleeve 6 and the second outer sleeve 3 can be It is a vulcanization integral molding process in the prior art.

[0044] The inner sleeve 4 is fixedly connected with an inner sleeve 5, and the inner sleeve 5 may be a metal cylinder in the prior art.

[0045] Both sides of the inner sleeve column 5 are fixedly connected with mounting seats 8, one side of the rubber sleeve 6 is provided with four first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com