Neodymium-iron-boron magnetic part automatic grinding mechanism and grinding method thereof

A technology of grinding mechanism and magnetic parts, applied in the direction of grinding frames, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of poor grinding quality of NdFeB magnetic parts, improve grinding fluency and save money Space, the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

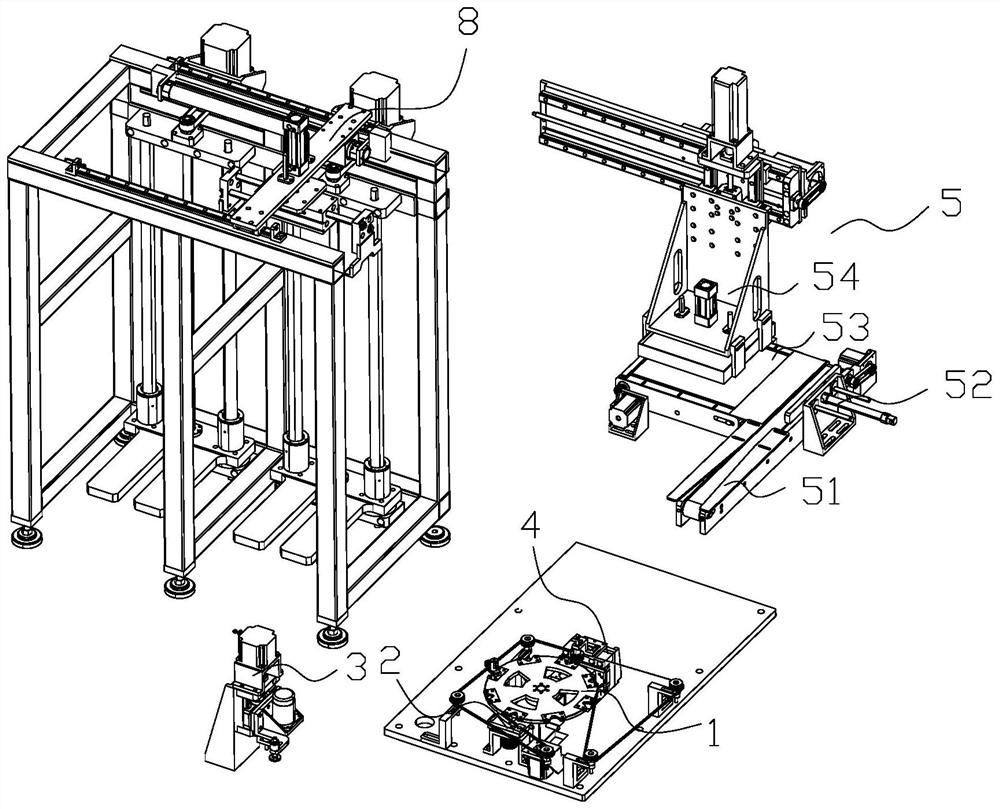

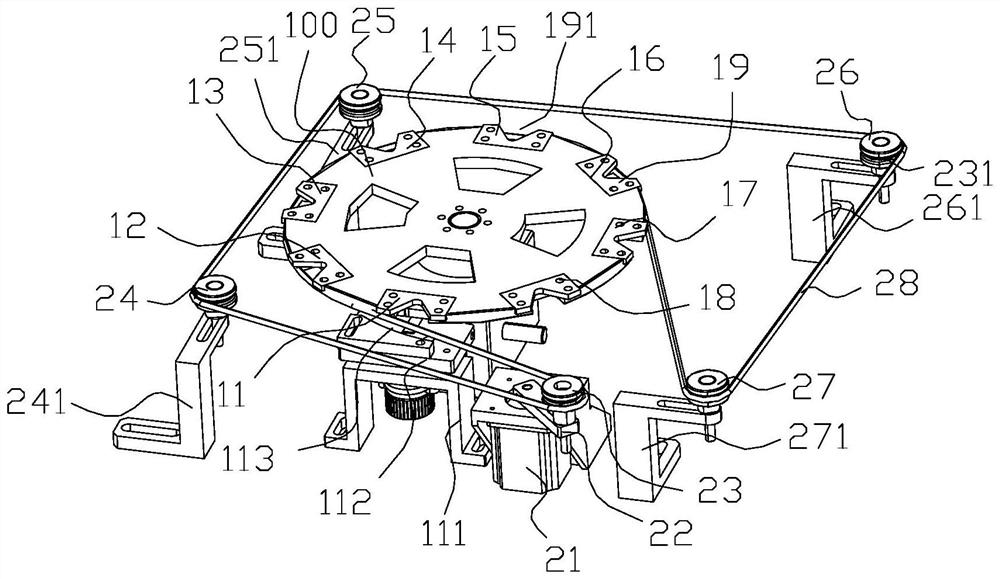

[0029] Such as figure 1 As shown, an automatic production equipment for NdFeB magnetic parts, the equipment includes a frame and an indexing device 1 on it, a magnetic part clamping device 2, a first grinding device 3, a second grinding device 4, a conveying transfer Device 5 and discharge device 8; the index plate 100 of index plate device 1 is provided with first station, second station 12, third station 13, fourth station 14, fifth station 15, The sixth station 16, the seventh station 17 and the eighth station 18; the magnetic part clamping device 2 is located on the outer ring of the indexing plate device 1; the magnetic part clamping device 2 is used for the indexing plate device 1 The first station 11, the second station 12, the third station 13, the fourth station 14, the fifth station 15, and the clamping limit of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com