Cleaning device and method for deep hole of engine cylinder block

A technology for engine cylinders and cleaning devices, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, and dry gas arrangement, which can solve the problems affecting the assembly accuracy of engine cylinders, the inability to completely remove burrs, and the impact on engine performance and service life and other issues, to achieve the effect of improving performance and service life, reducing production costs, and improving removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

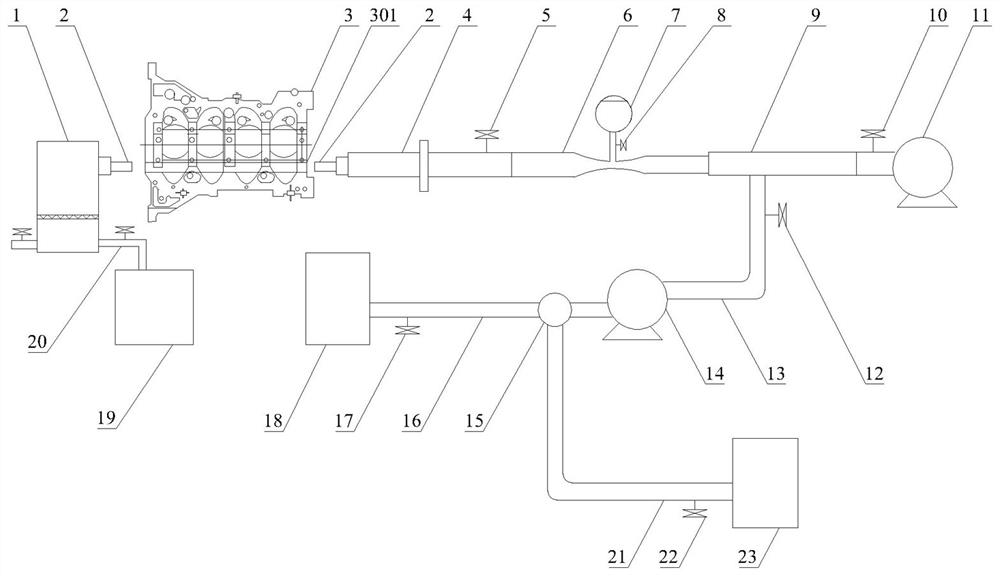

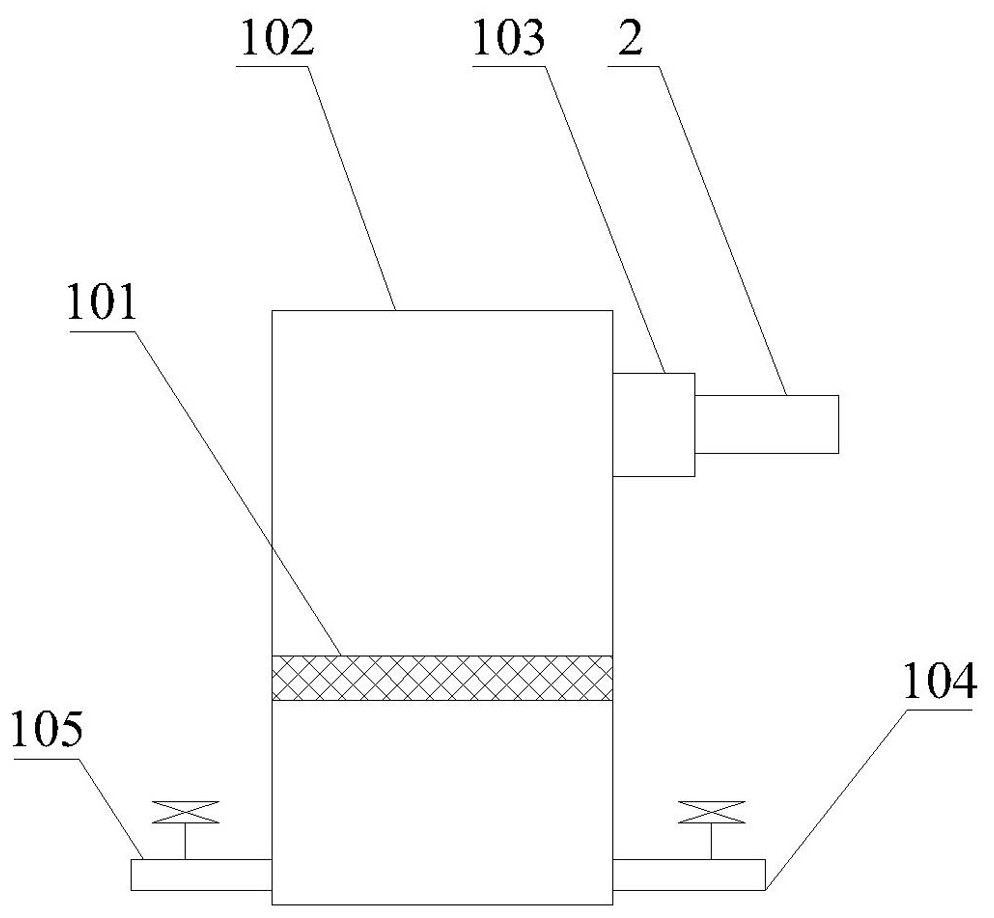

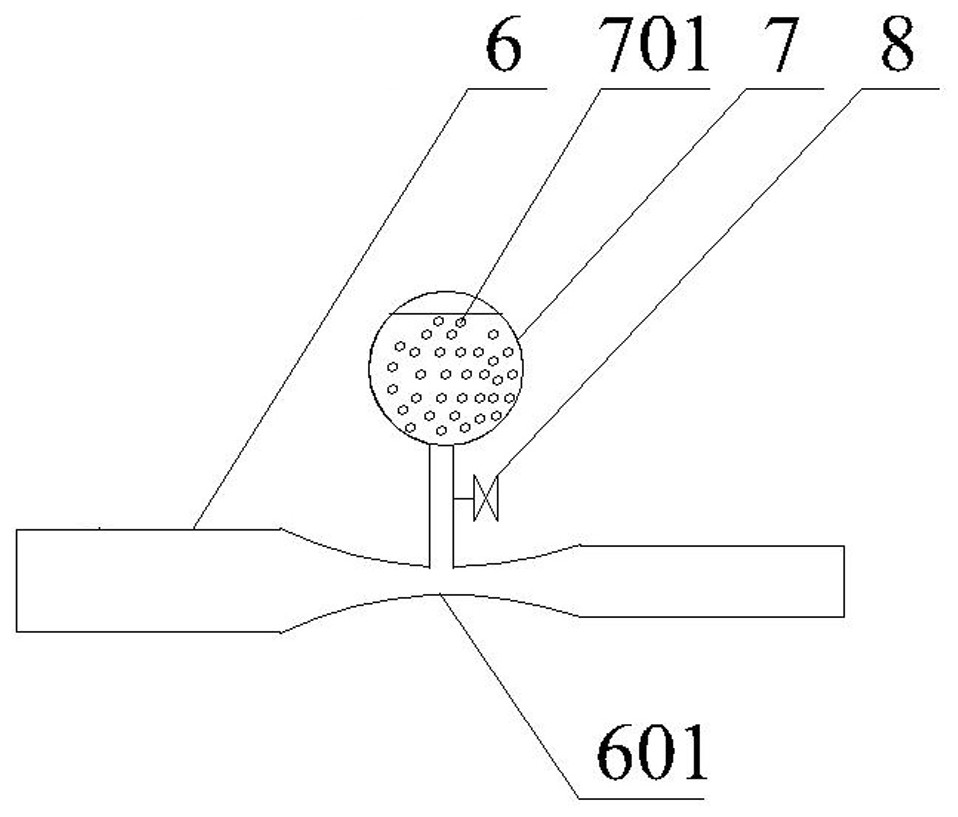

[0035] A deep hole cleaning device for an engine block, comprising a connecting pipe 4, a compressed air pump 11, a cleaning device and a nylon sand feeding device, the connecting pipe 4 is provided with a first cleaning valve 5, and one end of the connecting pipe 4 is provided with a Connect the joint 2 of the engine oil passage hole 301. In practice, the joint 2 matches the engine oil passage hole 301 of the engine block 3, and the connecting pipe 4 can be set in a telescopic structure, so that the joint can be better connected during use. 2 communicate with the engine oil passage hole 301.

[0036] The outlet of the compressed air pump 11 is connected with a blowing pipe 9, and the outlet of the compressed air pump 11 is provided with an air valve 10, and the compressed air pump 11 can be selected to have a working pressure of 0.5MPa-0.6MPa;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com