Independent air chamber jigger

An air chamber and jig technology, applied in the field of jigs, can solve the problems of reducing equipment reliability, affecting valves, affecting sorting effects, etc., and achieving the effects of reducing production costs, improving production efficiency, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

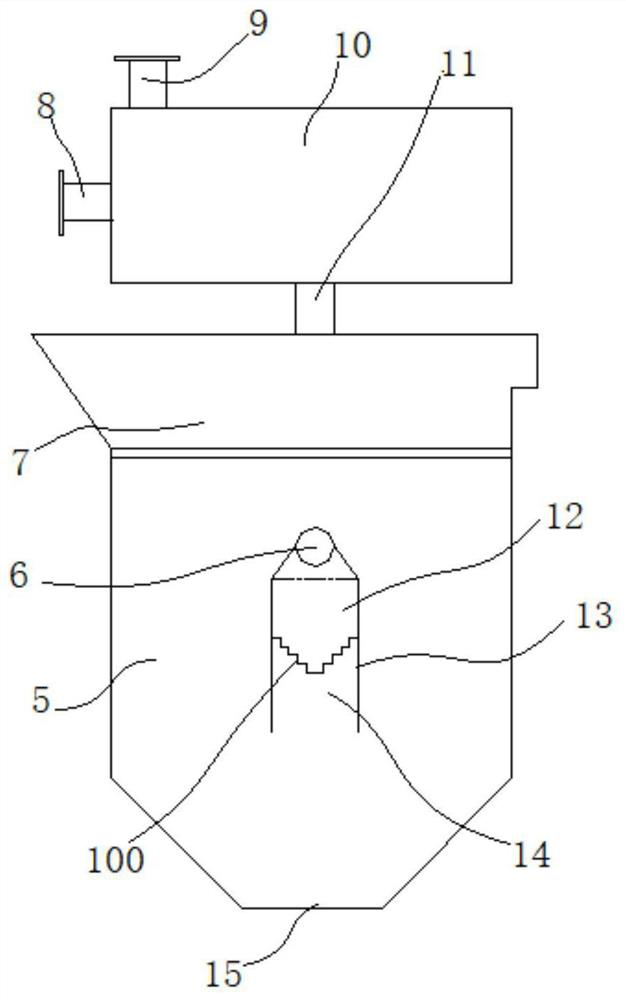

[0040] Such as image 3 with Figure 4 Shown, a kind of independent air chamber jigging machine comprises compressed air source, bellows 10 and the jigging chamber 5 that has screening groove 7 at the top;

[0041] The bellows 10 is provided with an air inlet end 8, an air outlet end 9 and an air supply end 11, an air inlet valve is arranged on the air inlet end 8, an air outlet valve is arranged on the air outlet end 9, and the compressed air source is connected to the air outlet through an air pipe. wind end 8;

[0042] The jigging chamber 5 is provided with a ventilation duct 6, one end of the ventilation duct 6 is blocked, and the other end extends out of the jigging chamber 5, and is connected to the air supply end 11 through the air duct;

[0043] A plurality of independent air chambers 13 are evenly distributed in the jigging chamber 5, each independent air chamber 13 is closed at the top and open at the bottom, and the independent air chamber 13 is provided with a de...

Embodiment 2

[0050] On the basis of Example 1, such as Figure 5 As shown, the bottom of the jigging chamber 5 has a sieve material discharge port 15, and the side wall of the jigging chamber 5 is provided with sorting impurities that are respectively connected to the sieve material discharge port 15 and the discharge end of the screening tank 7. Channel 17, the sorting impurity channel 17 is provided with a discharge device, and the screening tank 7 is provided with a bed thickness detection device, the bed thickness detection device and the discharge device are respectively electrically connected to the controller, and the controller obtains the bed thickness detection device. The bed thickness signal fed back by the device controls the operation of the discharge device, so that the sorted impurities in the jig chamber 5 are discharged through the sorted impurity channel 17 .

[0051] Preferably, the bed thickness detection device adopts a bed thickness sensor 16 .

[0052] Preferably, ...

Embodiment 3

[0055] On the basis of Example 2, such as Figure 6 As shown, a plurality of independent air chambers 13 are distributed side by side in at least two rows in the jigging chamber 5, and each row of independent air chambers 13 is respectively provided with a ventilation duct 6, and the independent air chambers 13 of the same row are connected in parallel to the corresponding ventilation ducts 6, Between the independent air chambers 13 of adjacent columns, a partition 19 whose lower end extends to the bottom of the jigging chamber 5 is arranged.

[0056] In this embodiment, the independent air chambers 13 of each column form a relatively independent jigging space through the partition plate 19, which avoids the mutual influence of the independent air chambers 13 of adjacent columns during the jigging process, and can ensure that the horizontal and vertical directions of the jigging machine are uniform. The pulsating water flow is conducive to the realization of large-scale equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com