Oil-in-water sunscreen lotion and preparation method thereof

A sunscreen and oil-in-water technology, which is applied in pharmaceutical formulations, cosmetic preparations, dressing preparations, etc. It can solve the problems of water resistance and sun protection index, reduce the UV protection function of sunscreen products, and the loss of UV protection agents. and other problems, to achieve the effect of excellent compatibility, safe use, and not easy to crystallize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0115] The second aspect of the present invention provides a method for preparing the above-mentioned oil-in-water sunscreen, comprising the following steps:

[0116] S1: Add the water phase components of Group A into the emulsification pot, heat to 80-85°C, stir to make them completely dissolved;

[0117] S2: Add the oil phase components of group B into the oil phase pot, heat to 80-85°C, stir to dissolve completely;

[0118] S3: adding the oil phase component of Group B after S2 treatment to the water phase component of Group A after S2 treatment, homogenize and emulsify evenly, stir and cool to 55-65°C to obtain Mixture 1;

[0119] S4: Add the components of group C to the mixture 1 obtained in S3, stir and homogenize until completely dissolved, and continue cooling to 40-50°C to obtain mixture 2;

[0120] S5: Mix and dissolve the components of group D completely, then put them into the mixture 2 obtained in S4, stir and mix until completely dissolved, and obtain mixture 3;...

Embodiment 1

[0134] Embodiment 1 provides an oil-in-water sunscreen, in parts by weight, the oil-in-water sunscreen includes 45 parts of water phase components of group A, 35 parts of oil phase components of group B, and 0.5 parts of components of group C , 0.5 parts of group D components, 15 parts of group E components;

[0135] The water phase components of the group A include water, glycerin, butylene glycol, carbopol, xanthan gum, sodium hyaluronate; the water, glycerin, butylene glycol, carbopol, xanthan gum, sodium hyaluronate The mass ratio is 30:4:3:0.1:0.1:0.01; the butanediol is 1,2-butanediol; the carbomer is TR-1, purchased from Lubrizol; the xanthan The grade of glue is XGN, purchased from Xin'an Chemical Co., Ltd.; the brand name of the sodium hyaluronate is HybloomTM sodium hyaluronate (HA-T), purchased from Huaxi Biotechnology Company;

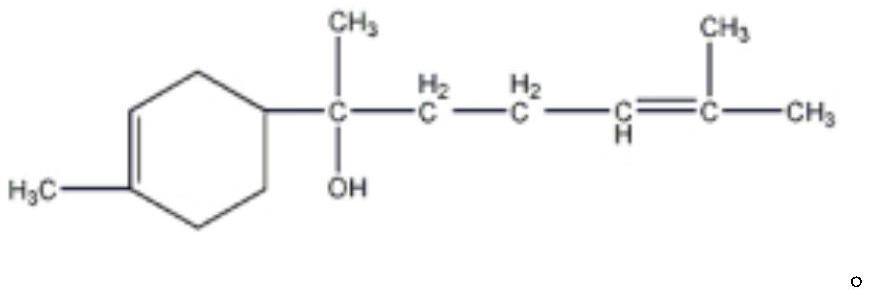

[0136] The oil phase component of the group B is a mixture of organic sunscreens, oils, skin feel modifiers, emulsifiers, and antioxida...

Embodiment 2

[0148] Example 2 provides an oil-in-water sunscreen, in parts by weight, the oil-in-water sunscreen includes 60 parts of the water phase component of group A, 45 parts of the oil phase component of group B, and 0.8 parts of the component of group C , 1.5 parts of group D components, 20 parts of group E components;

[0149] The water phase components of group A are the same as in Example 1, except that the mass ratio of water, glycerin, butylene glycol, carbopol, xanthan gum, and sodium hyaluronate is 40:4:5:0.2 :0.3:0.03;

[0150] The oil phase components of Group B are the same as in Example 1, except that the mass ratio of the organic sunscreen, oil, skin feel regulator, emulsifier, and antioxidant is 26:12:0.1:5:0.15;

[0151] The C group components are the same as in Example 1;

[0152] The D group components are the same as in Example 1;

[0153] The E group components are the same as in Example 1, except that the mass ratio of phenoxyethanol, dipotassium glycyrrhizina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com