Heating element, micro-heater and preparation method of micro-heater

A heating element and micro heater technology, applied in heating elements, heating element materials, ohmic resistance heating parts, etc., can solve problems such as poor stability and short service life, and achieve good high temperature stability, long service life, and cold state. Good resistance value stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

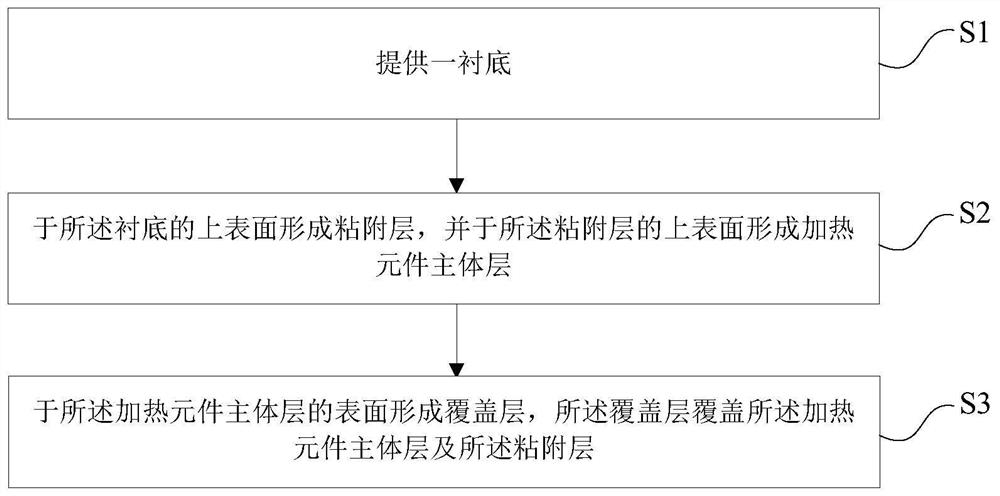

[0062] Please refer to figure 1 , the invention provides a kind of preparation method of heating element, the preparation method of described heating element comprises the following steps:

[0063] 1) providing a substrate;

[0064] 2) forming an adhesive layer on the upper surface of the substrate, and forming a heating element main body layer on the upper surface of the adhesive layer;

[0065] 3) forming a covering layer on the surface of the heating element main body layer, the covering layer covering the heating element main body layer and the adhesive layer.

[0066] In step 1), please refer to figure 1 Step S1 in and figure 2 , providing a substrate 1 .

[0067] As an example, the substrate 1 may include but not limited to a silicon substrate; preferably, the substrate 1 may include an N-type single throw or double throw single crystal silicon substrate; more preferably, in this implementation, the The substrate 1 can be an N-type single-polished or double-polishe...

Embodiment 2

[0081] read on Figure 2 to Figure 4 , the present invention also provides a heating element, the heating element includes: an adhesive layer 2; a heating element main body layer 3, the heating element main body layer 3 is located on the upper surface of the adhesive layer 2; a covering layer 4, the The cover layer 4 covers the adhesive layer 2 and the heating element main body layer 3 .

[0082] As an example, the heating element can be formed on a substrate, and the substrate 1 can include but not limited to a silicon substrate; preferably, the substrate 1 can include an N-type single throw or double throw single crystal silicon substrate More preferably, in this implementation, the substrate 1 may be an N-type single- or double-throw single crystal silicon substrate with (100) or (111) crystal orientation.

[0083] As an example, the material of the adhesion layer 2 may include but not limited to tantalum (Ta). For example, the material of the adhesion layer 2 may be titan...

Embodiment 3

[0091] Please refer to Figure 5 , the present invention also provides a kind of preparation method of micro-heater, the preparation method of described micro-heater comprises:

[0092] 1) Provide a substrate:

[0093] 2) forming a support layer on the upper surface of the substrate;

[0094] 3) forming an adhesive layer on the upper surface of the support layer, and forming a heating element main body layer on the upper surface of the adhesive layer;

[0095] 4) forming a covering layer on the surface of the heating element main body layer, the covering layer covering the heating element main body layer and the adhesive layer;

[0096] 5) forming test electrodes on the upper surface of the support layer and the upper surface of the covering layer;

[0097] 6) Etching the support layer to form a main support layer, a peripheral support layer and a support beam, the peripheral support layer is located at the periphery of the main support layer and has a gap with the main sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com