Coal gas premixing device, and coal gas heat value detection device and method

A gas pre- and gas mixing technology, which is applied in combustion methods, material thermal development, gas fuel burners, etc., can solve the problem that the calorific value measurement method of industrial furnaces and gas pipe networks cannot meet the calorific value measurement of various types of gas. , to achieve the effect of saving equipment investment costs, shortening measurement response time, and rapid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

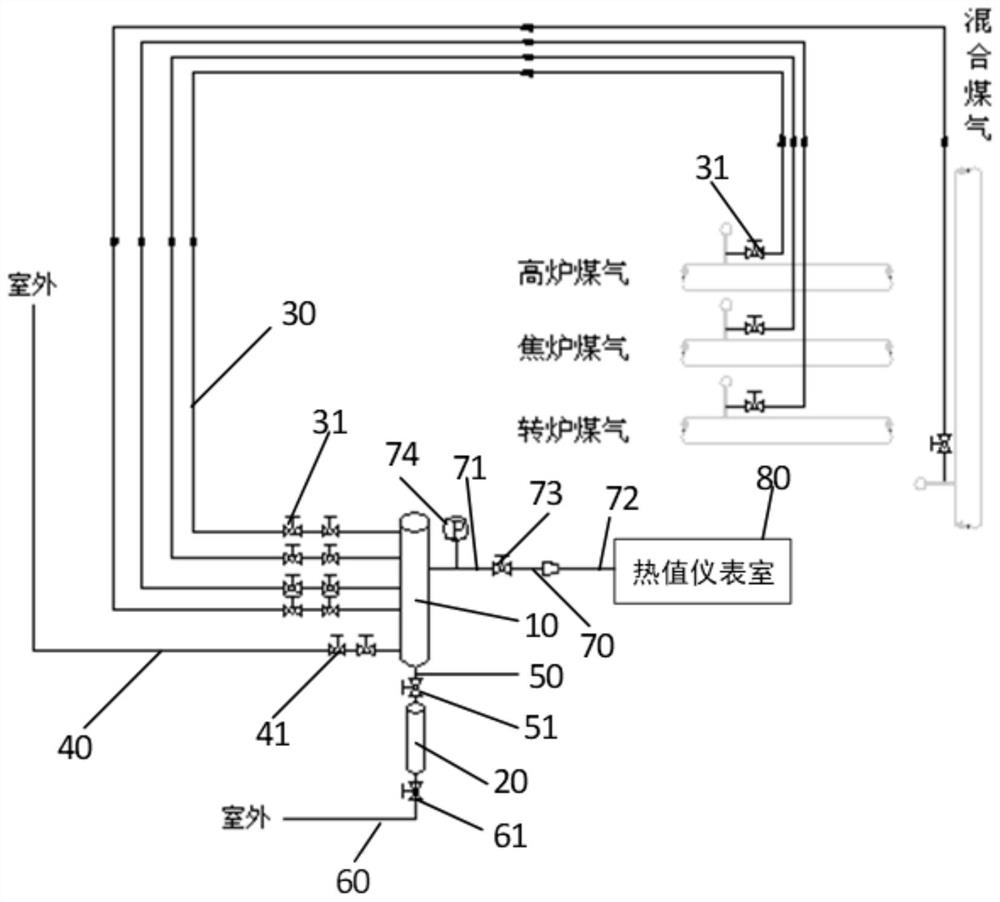

[0043] like figure 1 As shown, the gas premixing device includes a gas mixing tank 10 , a settling sewage tank 20 , a plurality of gas pipes 30 , a discharge pipe 40 , a settling pipe 50 , a sewage pipe 60 and an instrument connecting pipe 70 .

[0044] One end of the plurality of gas pipes 30 is respectively connected to different gas pipelines, and the other end is connected to the gas mixing tank 10 . In this embodiment, the number of gas pipes 30 is four, which are respectively connected to mixed gas pipelines, blast furnace gas pipelines, coke oven gas pipelines, and converter gas pipelines. In other embodiments, the number of gas pipes 30 can also be set to 2, 3, 5, etc., and the gas pipes can also include natural gas pipes, which can be set according to actual conditions, and are not limited here.

[0045] Further, in the plurality of gas pipes 30, the end of each gas pipe 30 connected to the gas pipeline and the end connected to the gas mixing tank 10 are provided wit...

Embodiment 2

[0054] Based on the same inventive concept, the present application also provides a coal gas calorific value detection device, which includes the gas premixing device and the calorific value instrument room 80 in the first embodiment.

[0055] Through the gas calorific value detection device provided by this application, various types of gas calorific value measurements developed for burners can be realized, which solves the problem that the calorific value measurement methods of industrial furnaces and gas pipeline networks in the prior art cannot meet the requirements developed for burners. Technical issues of calorific value measurement of various types of gas.

Embodiment 3

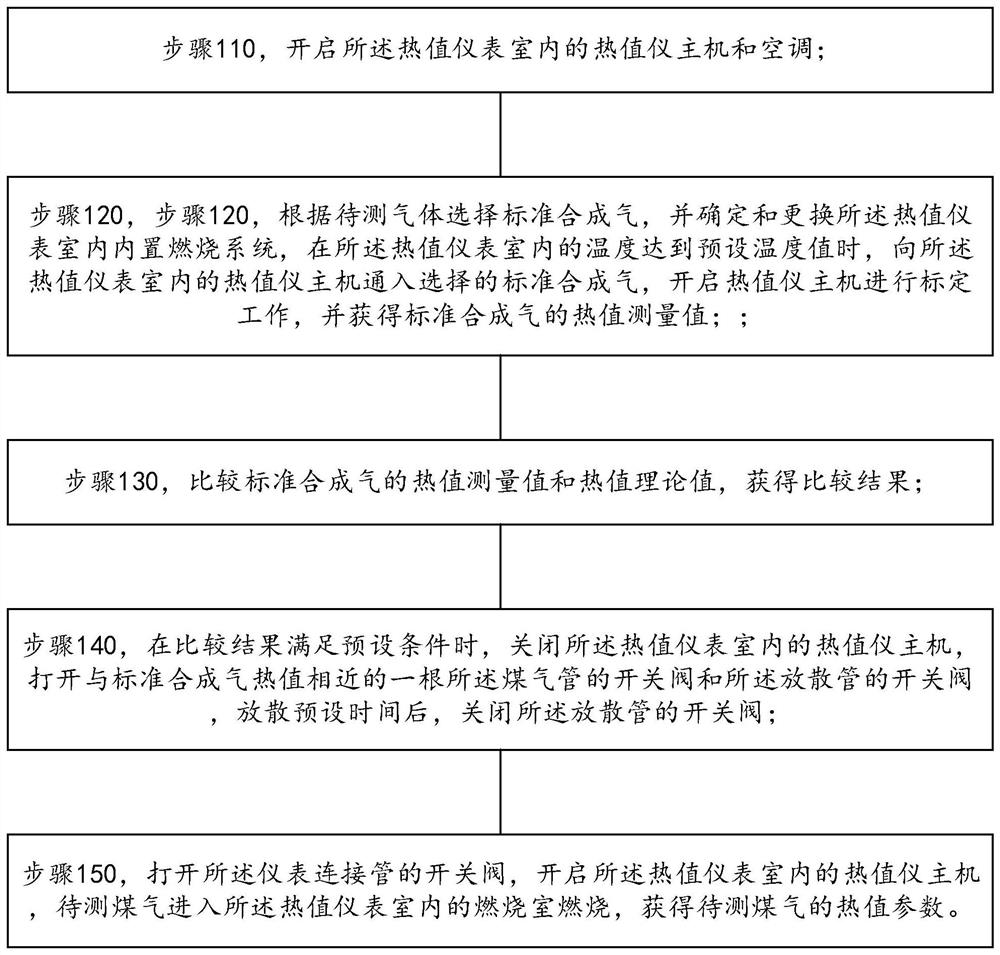

[0057] Based on the same inventive concept, the present application also provides a gas calorific value detection method, such as figure 2 As shown, the gas detection method is applied to a gas calorific value detection device, and the detection method includes:

[0058] Step 110, turn on the calorific value meter host and the air conditioner in the calorific value meter room 80 .

[0059] Through the cooling or heating of the air conditioner, the temperature in the calorific value instrument room reaches the preset temperature value, and the temperature fluctuation is guaranteed not to exceed 1-2°C / h. Specifically, in this embodiment, the preset temperature value is specifically 20° C., which can be adjusted as required.

[0060] In addition, since an exhaust fan and an alarm are also arranged in the calorific value instrument room 80, the exhaust fan and the alarm can be turned on at the same time. The exhaust fan is used for gas ventilation in the calorific value instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com