Sulfur-containing natural gas sampling system

A sampling system and natural gas technology, applied in the field of sulfur-containing natural gas sampling systems, can solve the problems of poor desulfurization effect, environmental pollution, unfavorable sampling operation safety, and smooth development, etc., and achieves low sulfur content, good desulfurization effect, and guaranteed desulfurization. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

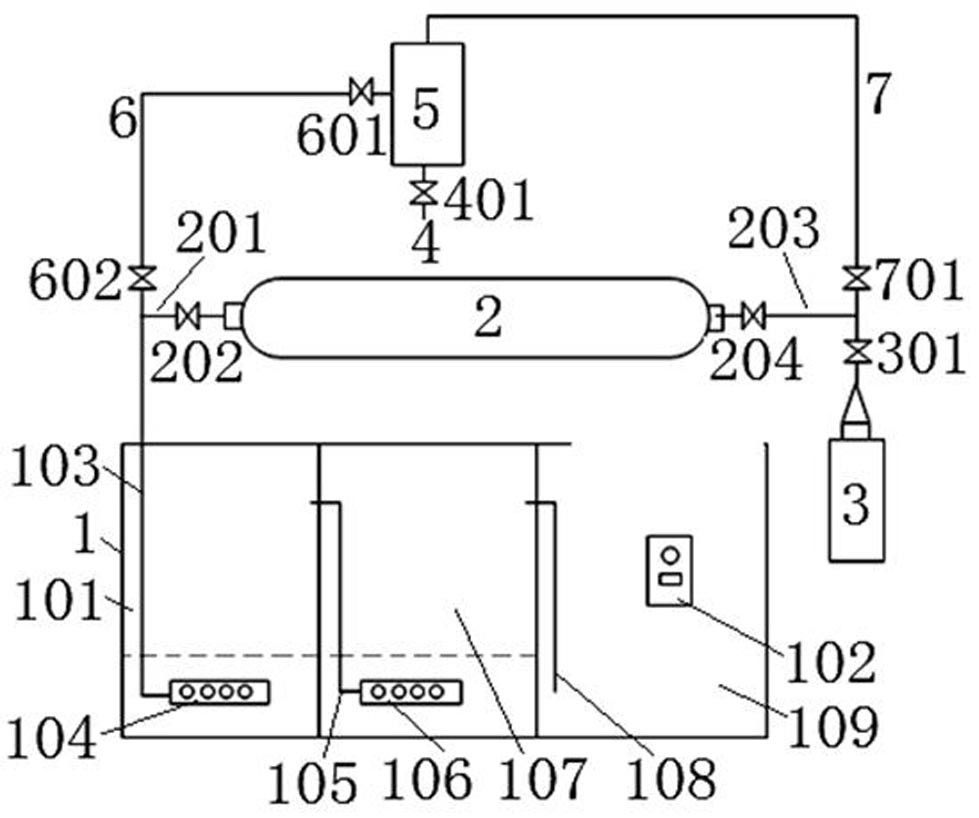

[0020] The present invention relates to a sampling system for gas detection, in particular to a sampling system for sulfur-containing natural gas. figure 1 The main technical content of the present invention will be described in detail.

[0021] What needs to be specially explained here is that the drawings of the present invention are schematic, and unnecessary details have been simplified in order to clarify the technical purpose of the present invention, so as to avoid obscuring the technical solutions that the present invention contributes to the prior art.

[0022] The present invention is a sampling system for sour natural gas sampling operations, see figure 1 As shown, the present invention includes a neutralization tank 1 , a sampling container 2 , an air pump 3 and a tee joint 5 .

[0023] Wherein, the neutralization box 1 is a box-type container structure, and the inside has a venting chamber 109 and two neutralization chambers—that is, a neutralization chamber one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com