Evaporator for snowflake ice maker

A technology for evaporators and ice machines, which is applied to evaporators/condensers, ice making, ice making, etc. It can solve problems such as the complex sealing structure of evaporators, and achieve the effect of simple structure, simple structure, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

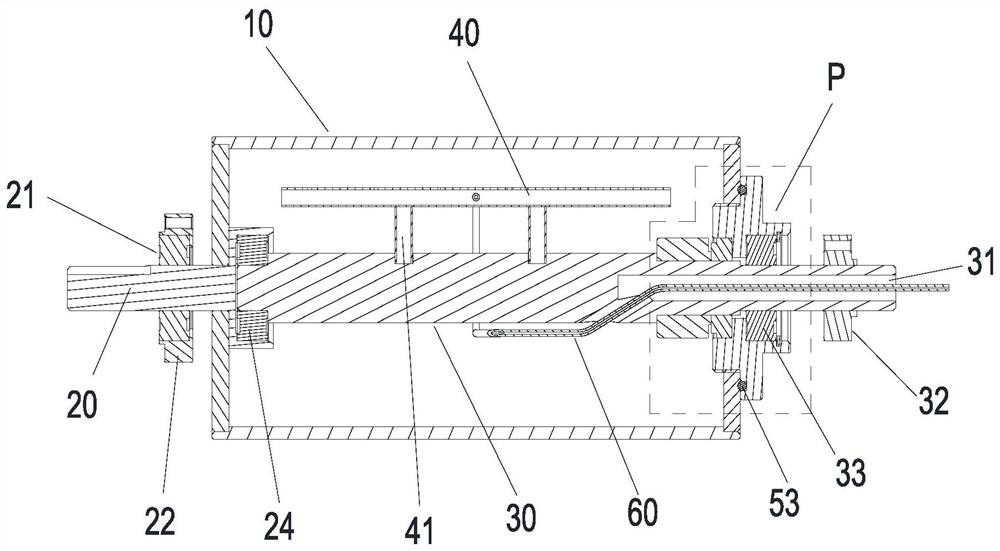

[0044] like figure 1 and figure 2 As shown, the evaporator for the snowflake ice machine of this embodiment includes:

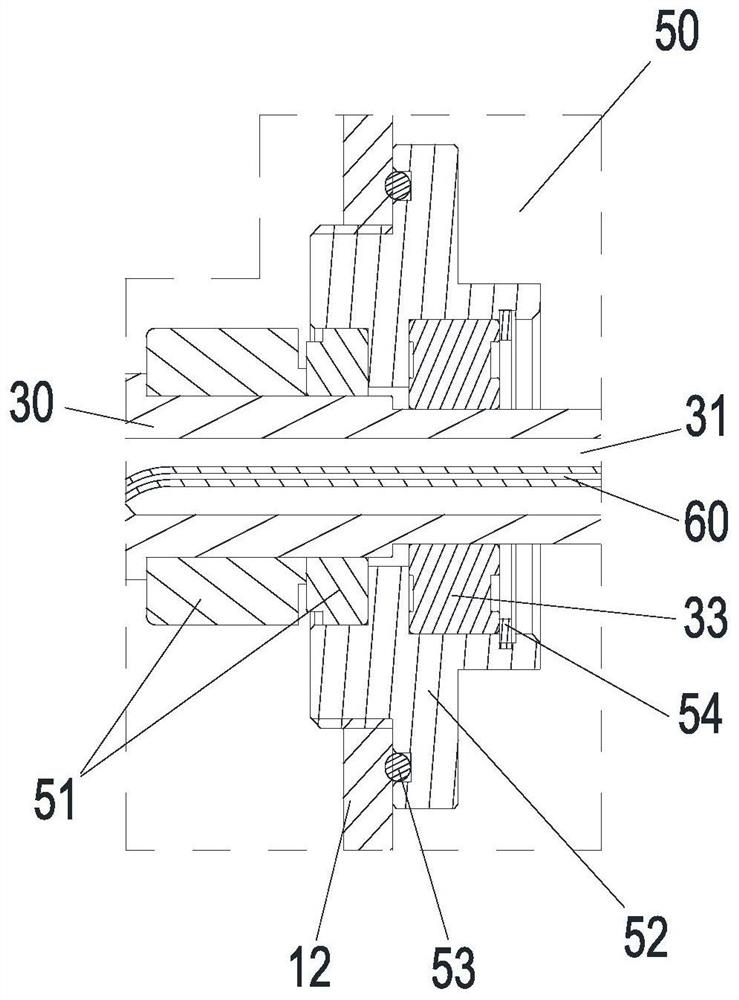

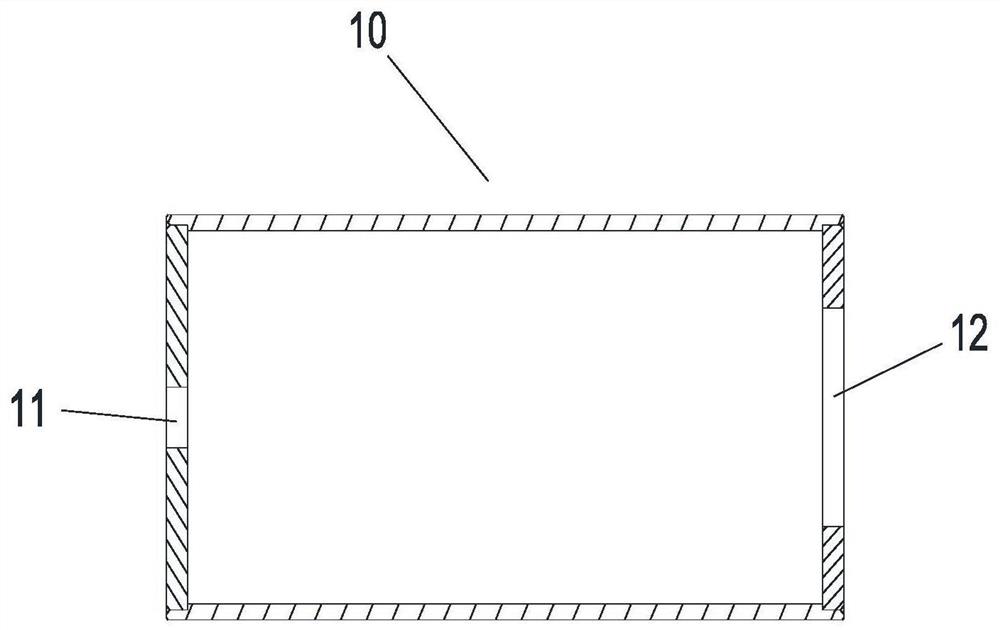

[0045] Cylinder 10, combined image 3 As shown, a fixed shaft 30 is pierced inside, and a first through hole 11 is formed on one side of the cylinder 10 and a drive shaft 20 is formed on one side of the cylinder 10, and a second through hole 12 is formed on the other side of the cylinder 10. The second through hole 12 is formed on the other side of the cylinder 10. A sealing mechanism 50 is arranged in the through hole 12;

[0046] drive shaft 20, combined with Figure 4 As shown, one end is provided with a cup-shaped opening 23, and this end is sleeved inside the cylinder 10 through the first through hole 11 of the cylinder 10, and a first bearing 24 is sleeved in the cup-shaped opening 23. , the drive shaft 20 is located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com