Self -clean vacuum cleaner and operation of the self -clean vacuum cleaner

A self-cleaning, vacuum cleaner technology, applied in the direction of cleaning filter devices, etc., can solve the problems of high cost, complicated process, complicated circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

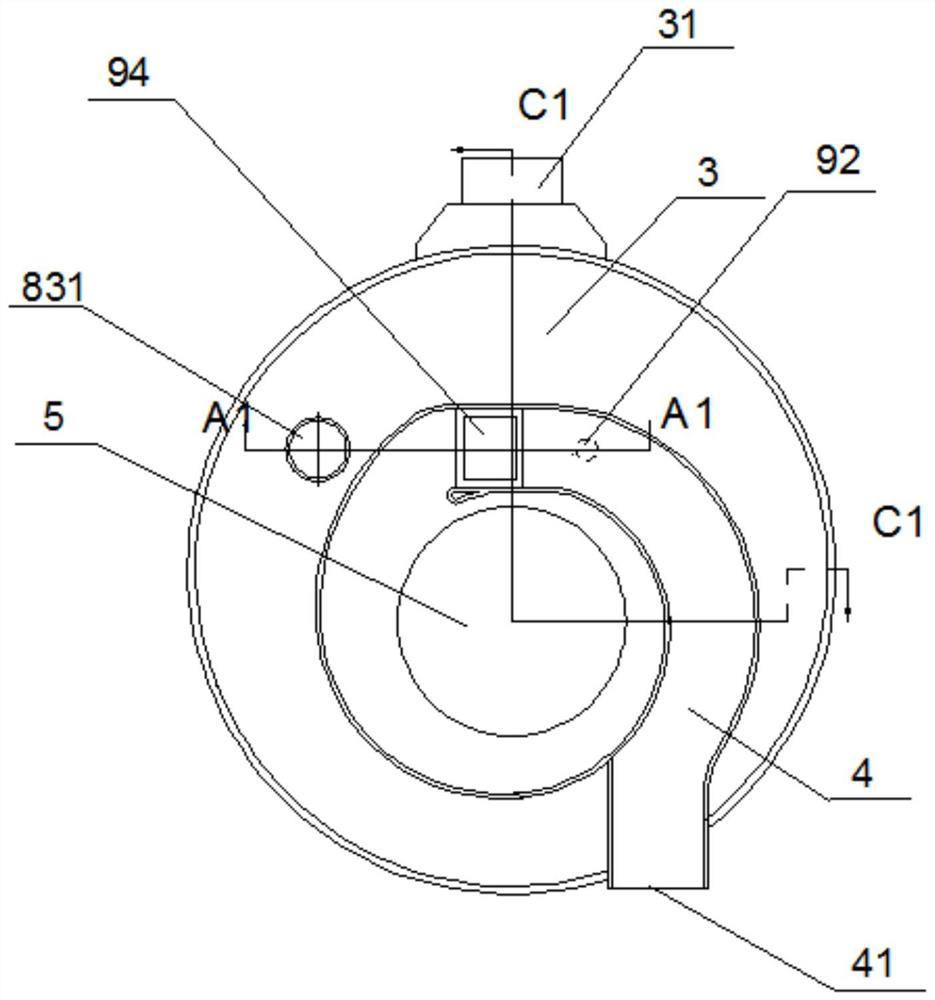

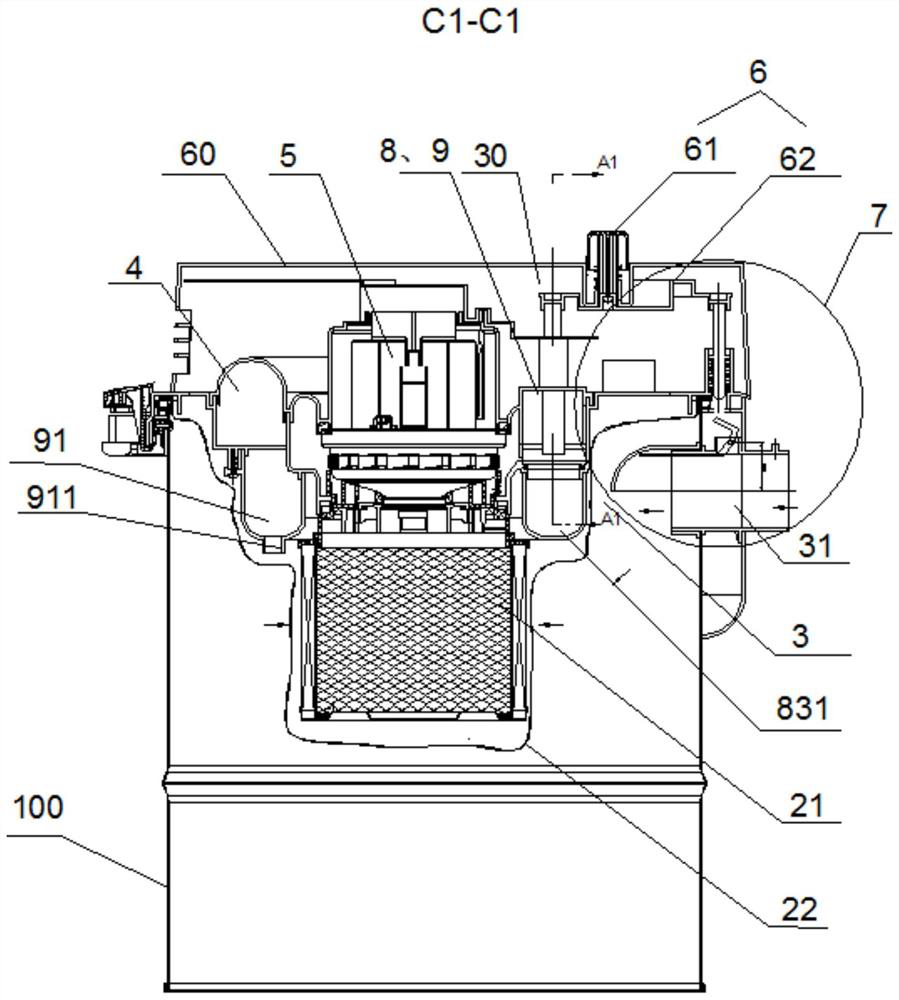

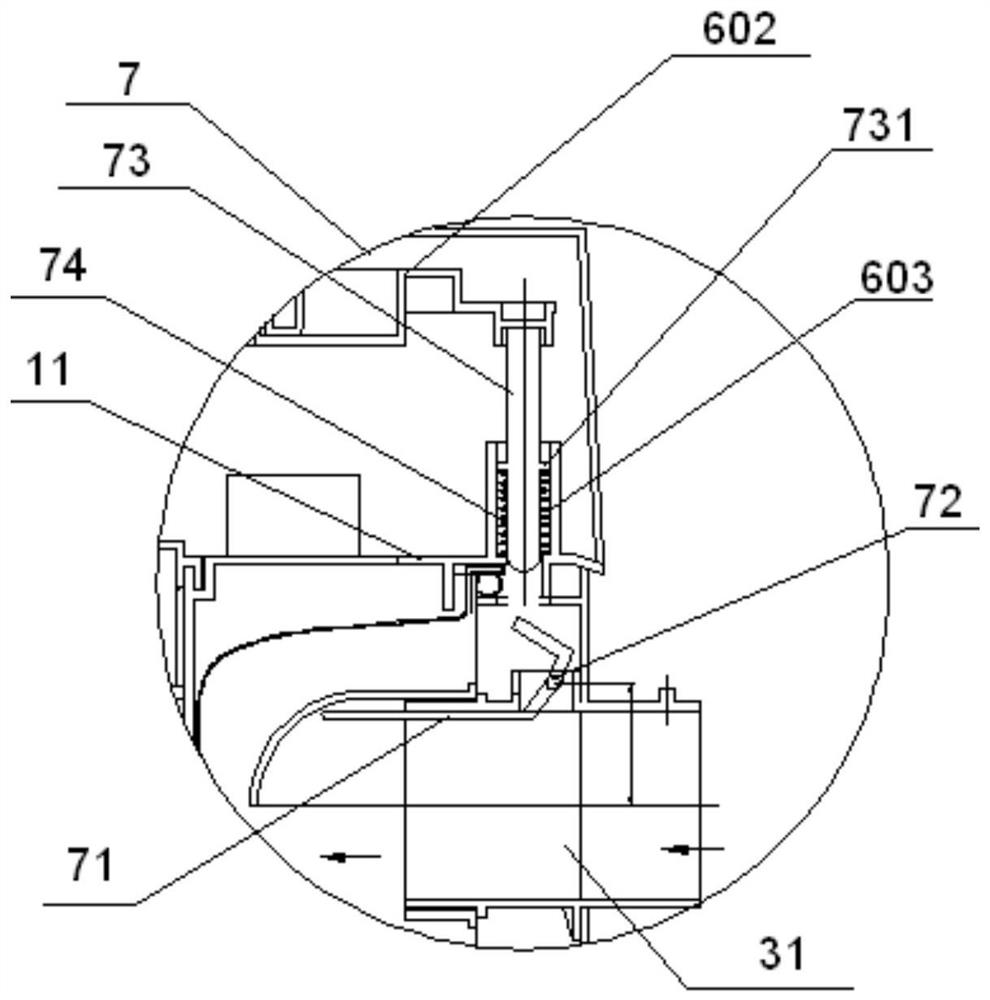

[0069] Embodiment one: if Figures 1 to 2 As shown, the present embodiment provides a self-cleaning vacuum cleaner and a method for operating the self-cleaning vacuum cleaner. The self-cleaning vacuum cleaner in this embodiment includes a machine head assembly and a bucket body 100 for collecting garbage. The bag 21 and the main filter 22 are arranged in the dust bag 21 . The head assembly is provided with an air inlet duct 3, an air outlet duct 4, and a motor 5, wherein the air inlet duct 3 runs through the entire barrel body 100, the air outlet duct 4 is a spiral air duct, and the motor 5 is located at the air inlet Between air duct 3 and outlet air duct 4. The upper part of the head assembly is provided with a cavity 30 , the cavity 30 retains gas when the vacuum cleaner is working, and this part of the gas is used as compensating wind for self-cleaning of the dust bag 21 during self-cleaning. The barrel body 100 is provided with a main air inlet 31 , and the air outlet ...

Embodiment 2

[0089] Embodiment two: if Figure 8 , 9 As shown in and 14, the present embodiment provides a self-cleaning vacuum cleaner and a method for operating the self-cleaning vacuum cleaner. The self-cleaning vacuum cleaner in this embodiment includes a machine head assembly and a bucket body 100 for collecting garbage. The bag 21 and the main filter 22 are arranged in the dust collecting bag 21 . The head assembly is also provided with an air inlet duct 3, an air outlet duct 4 and a motor 5, wherein the air inlet duct 3 runs through the entire barrel body 100, the air outlet duct 4 is a spiral air duct, and the motor 5 is positioned at the inlet air duct. Between channel 3 and air outlet channel 4. The upper part of the head assembly is provided with a cavity 30 , the cavity 30 retains gas when the vacuum cleaner is working, and this part of the gas is used as compensating wind for self-cleaning of the dust bag 21 during self-cleaning. The barrel body 100 is provided with a main...

Embodiment 3

[0117] Embodiment three: as Figures 19 to 20 As shown, the present embodiment provides a self-cleaning vacuum cleaner and a self-cleaning method for operating the self-cleaning vacuum cleaner. The self-cleaning vacuum cleaner in this embodiment includes a machine head assembly and a bucket body 100 for collecting garbage. The bag 21 and the main filter 22 are arranged in the dust bag 21 . The head assembly is also provided with an air inlet duct 3, an air outlet duct 4 and a motor 5, wherein the air inlet duct 3 runs through the entire barrel body 100, the air outlet duct 4 is a spiral air duct, and the motor 5 is positioned at the inlet air duct. Between channel 3 and air outlet channel 4. The upper part of the head assembly is provided with a cavity 30 , the cavity 30 retains gas when the vacuum cleaner is working, and this part of the gas is used as compensating wind for self-cleaning of the dust bag 21 during self-cleaning. The barrel body 100 is provided with a main a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com