Chain stitch loosing prevention device

A chain stitch and anti-loosening technology, applied in the field of sewing machines, can solve problems such as affecting the appearance and performance, hanging cloth, complex structure, etc., and achieve the effect of solving the appearance of cumbersome, avoiding the loosening of the stitches, and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

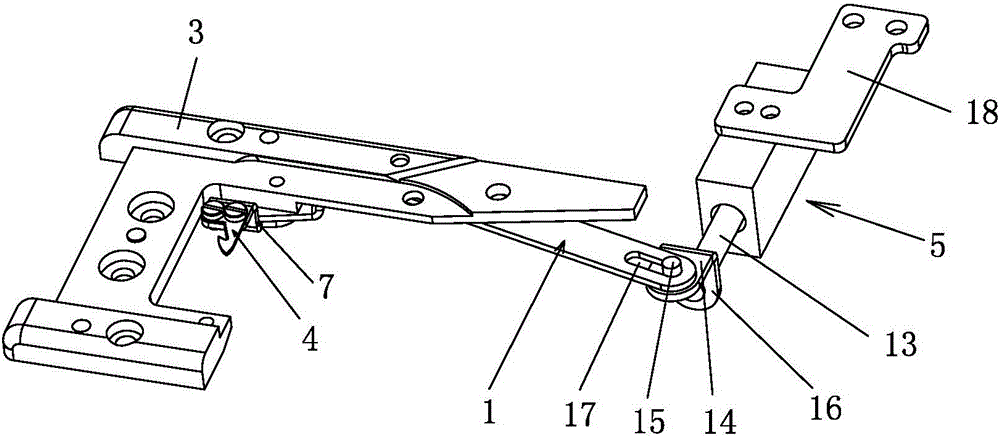

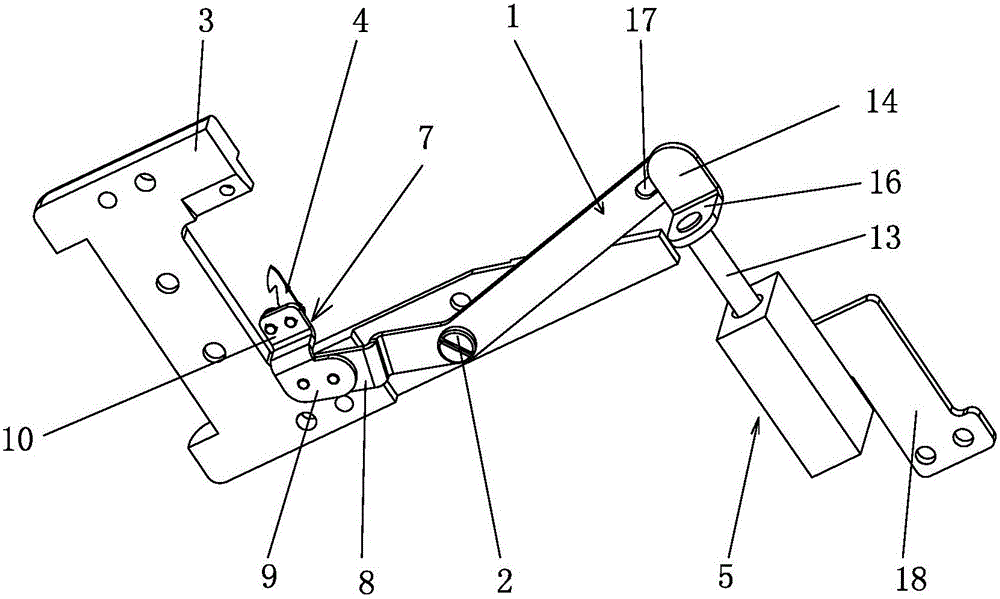

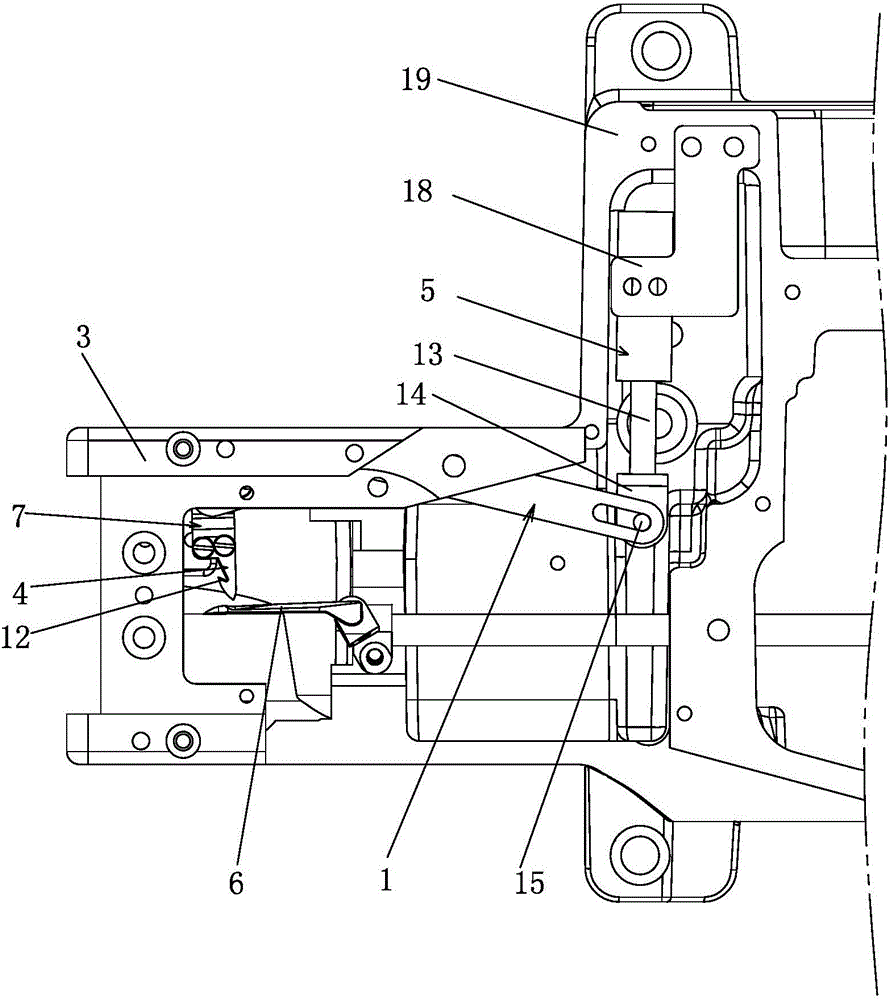

[0022] The present invention will be further described below with specific embodiment, see figure 1 —4:

[0023] A chain stitch anti-loosening device includes a swing rod 1, and the swing rod 1 is installed under a needle board frame 3 through an installation shaft 2. The mounting shaft 2 can be a shaft screw or a pin shaft. What this embodiment adopts is the axial screw. One end of the swing rod 1 is provided with a cutter head 4, and the other end is connected with the drive source 5. Under the action of the drive source 5, the swing rod 1 can swing around the installation shaft 2 and then drive the cutter head 4 away from the looper 6 or toward the top of the looper 6. Movement, the action of the drive source 5 is controlled by the electric control box.

[0024] The cutter head 4 is installed on the cutter head mounting seat 7 , and the cutter head mounting seat 7 is arranged on one end of the swing rod 1 .

[0025] Since the swing rod 1 is located below the needle plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com