Button surface heat treatment forming equipment

A technology of surface heat treatment and forming equipment, which is applied in heat treatment equipment, heat treatment furnaces, presses for material forming, etc., can solve the problems of low work efficiency, laborious, troublesome, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

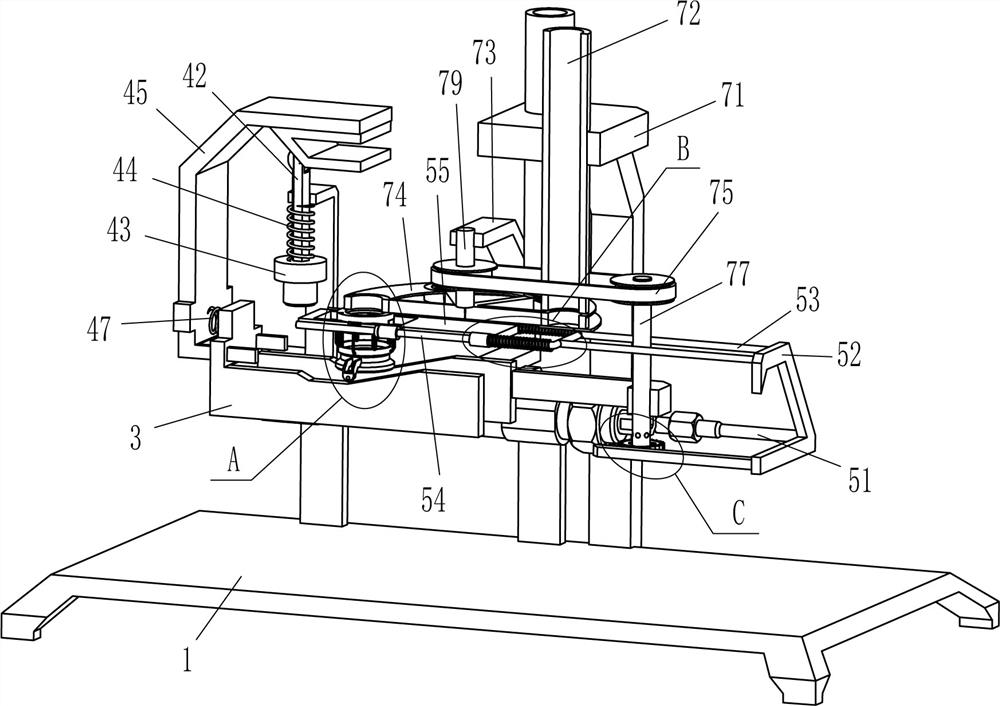

[0027] A button surface heat treatment forming equipment, such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 As shown, it includes a base 1, an L-shaped plate 2, a special-shaped plate 3, a stamping mechanism 4, a driving mechanism 5 and a placement mechanism 6. Two L-shaped plates 2 and four A special-shaped plate 3 is fixedly connected between the inner ends of the L-shaped plates 2, and the left part of the special-shaped plate 3 is provided with a stamping mechanism 4, and a drive mechanism 5 is provided between the inner side of the four L-shaped plates 2 and the special-shaped plate 3, and the drive mechanism 5 is connected to the special-shaped plate 3. The stamping mechanism 4 cooperates, and the driving mechanism 5 is provided with a placement mechanism 6, which contacts and cooperates with the special-shaped plate 3.

[0028]Stamping mechanism 4 includes n-type plate 41, movable slide bar 42, stamping head 43, first spring 44, special-shaped slide ...

Embodiment 2

[0036] On the basis of Example 1, such as figure 1 , figure 2 and Figure 7 As shown, a blanking mechanism 7 is also included, and the blanking mechanism 7 includes a fixed frame 71, a discharge pipe 72, a mounting frame 73, a porous placement plate 74, a transmission assembly 75, a mounting block 76, a rotating rod 77, and a gap plate 78 , rotating shaft 79, ratchet wheel 710 and ratchet bar 711, mounting frame 73 is fixedly connected between the upper part of the right side of the front and rear sides of the special-shaped plate 3, the rotating shaft 79 is connected in the middle of the mounting frame 73 top, and the bottom end of the rotating shaft 79 is fixedly connected There is a porous disc 74, and a notch disc 78 is fixedly connected between the upper and lower sides of the mounting frame 73. The gap of the notch disc 78 is matched with the annular block 61, and the top of the notch disc 78 is in contact with the bottom of the porous disc 74. 3. A mounting block 76 ...

Embodiment 3

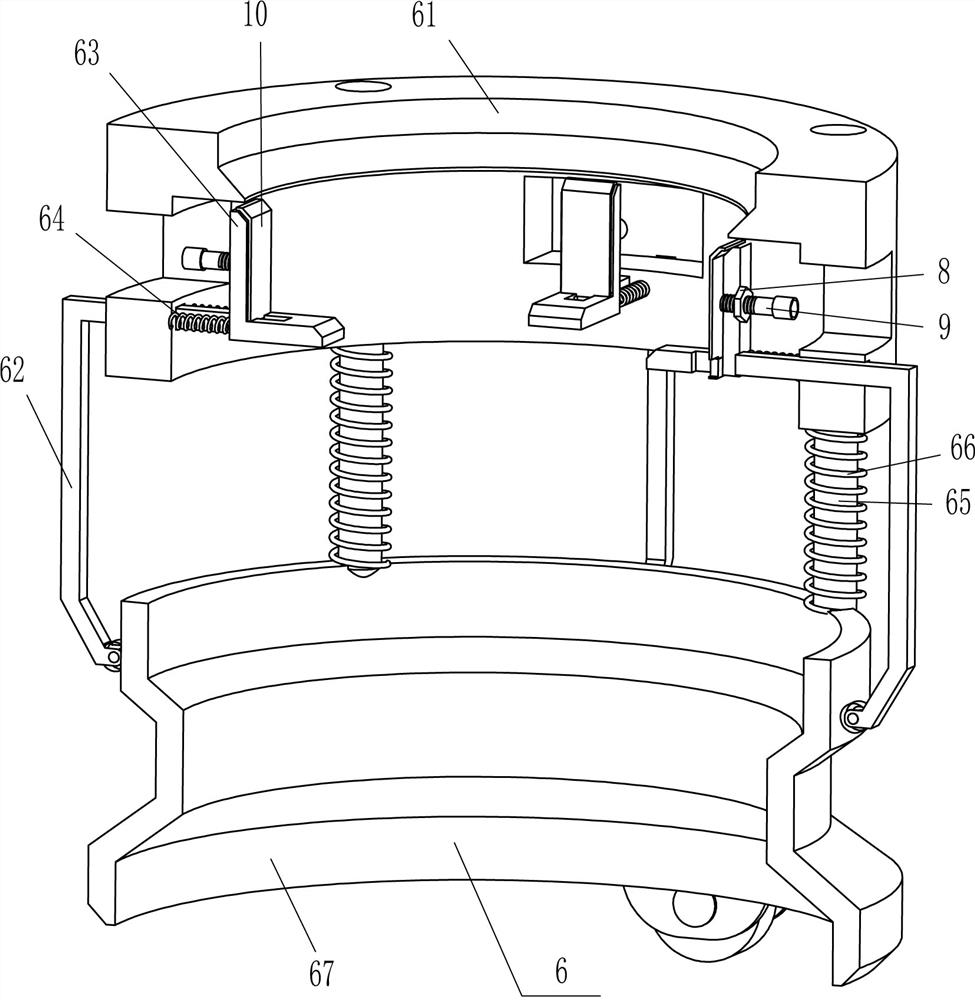

[0039] On the basis of embodiment 1 and embodiment 2, such as figure 2 , image 3 , Figure 4 and Figure 7 As shown, it also includes a nut 8, a screw rod 9 and a movable plate 10, the upper middle of the outer surface of the L-shaped placement plate 63 is fixedly connected with a nut 8, the screw rod 9 is threaded on the nut 8, and the inner end of the screw rod 9 runs through the L-shaped placement plate 63 The movable plate 10 is connected with the rotary type, and the bottom of the movable plate 10 is slidably matched with the inner bottom of the L-shaped placing plate 63 .

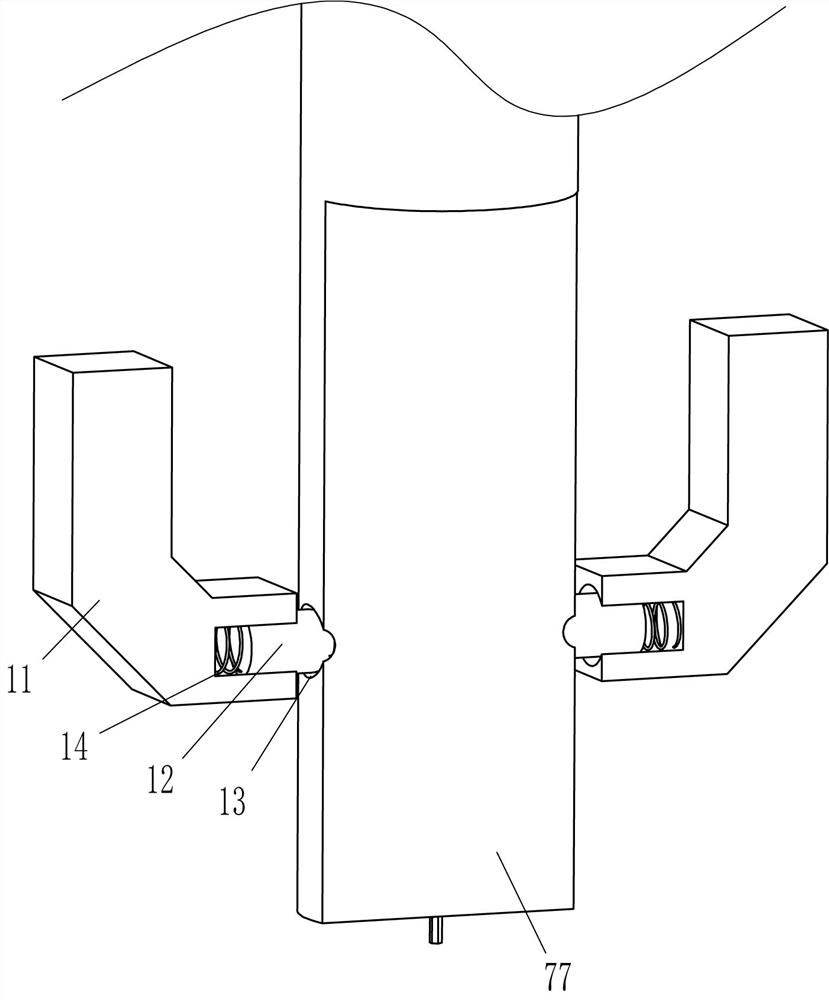

[0040] It also includes an L-shaped block 11, a clamping rod 12 and a sixth spring 14, six clamping holes 13 are evenly spaced around the lower part of the rotating rod 77, and an L-shaped block 11 is fixed symmetrically on the right side of the bottom of the mounting block 76. , the inner ends of the L-shaped blocks 11 on the front and rear sides are slidably placed with clamping rods 12, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com