Mildew-proof antibacterial water-based ink for printing packaging carton and production method of mildew-proof antibacterial water-based ink

A carton printing, anti-mildew and anti-bacterial technology, which is applied in the field of anti-mold and anti-bacterial packaging carton printing water-based ink and its production field, can solve the problems of reducing the performance of water-based ink, damage to the ink system, and poor anti-bacterial effect, so as to improve anti-bacterial performance, Good inhibitory ability and strong ability to kill mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

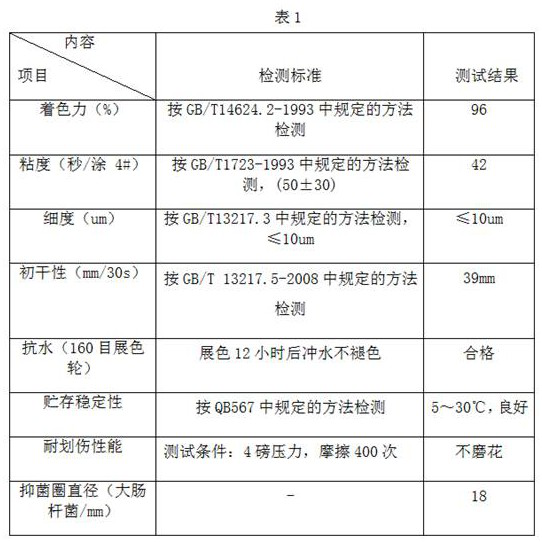

Image

Examples

Embodiment 1

[0026] A water-based ink for mildew-proof and antibacterial packaging carton printing, comprising the following raw materials in parts by weight: 60 parts of water-soluble acrylic resin; 25 parts of water-based pigment; 2 parts of isopropanol; 0.3 part of chitosan; 0.6 part of cinnamon oil; 0.5 parts of antibacterial agent octyl-isothiazolinone; 3 parts of triethanolamine buffer with a pH value of 8.5; 0.2 parts of sodium lauryl sulfate; 0.2 parts of GPE defoamer; 3 parts of propylene glycol alginate; 45 parts of water ;

[0027] The production method of the water-based ink for mildew-proof and antibacterial packaging carton printing comprises the following steps:

[0028] (1) Take the raw materials according to the parts by weight for later use, first add water to the reaction kettle, control the temperature of the reaction kettle at 80°C, then slowly add water-soluble acrylic resin, isopropanol and GPE defoaming under stirring conditions agent, keep warm for 50 minutes, mix...

Embodiment 2

[0033] A water-based ink for mildew-proof and antibacterial packaging carton printing, comprising the following raw materials in parts by weight: 65 parts of water-soluble acrylic resin; 27 parts of water-based pigment; 3 parts of isopropanol; 0.2 part of chitosan; 0.5 part of cinnamon oil; 0.7 parts of antibacterial agent octyl-isothiazolinone; 4 parts of dimethylacetamide buffer with a pH value of 8.5; 0.3 parts of sodium lauryl sulfate; 0.3 parts of GPE defoamer; 4 parts of propylene glycol alginate; 50 parts of water;

[0034] The production method of the water-based ink for mildew-proof and antibacterial packaging carton printing comprises the following steps:

[0035] (1) Take the raw materials according to the parts by weight for later use, first add water into the reactor, control the temperature of the reactor at 85°C, and then slowly add water-soluble acrylic resin, isopropanol and GPE defoaming under stirring conditions agent, keep warm for 45 minutes, mix and stir...

Embodiment 3

[0040] A water-based ink for mildew-proof and antibacterial packaging carton printing, comprising the following raw materials in parts by weight: 68 parts of water-soluble acrylic resin; 27 parts of water-based pigment; 3.5 parts of isopropanol; 0.25 parts of chitosan; 0.8 parts of cinnamon oil; 0.8 parts of antibacterial agent octyl-isothiazolinone; 4.5 parts of triethanolamine buffer with a pH value of 8.5; 0.35 parts of sodium lauryl sulfate; 0.35 parts of GPE defoamer; 4.5 parts of propylene glycol alginate; 52 parts of water ;

[0041] The production method of the water-based ink for mildew-proof and antibacterial packaging carton printing comprises the following steps:

[0042] (1) Take the raw materials according to the parts by weight for later use, first add water to the reaction kettle, control the temperature of the reaction kettle between 80°C and 90°C, then slowly add water-soluble acrylic resin, isopropyl Alcohol and GPE defoamer, keep warm for 45 minutes, mix a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com