Supercritical water oxidation reactor and supercritical water oxidation system

A supercritical water oxidation and reactor technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of large consumption of sacrificial layers, complicated operation, hidden safety hazards, etc., to avoid Local enrichment, intensifying heat and mass transfer, and preventing local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

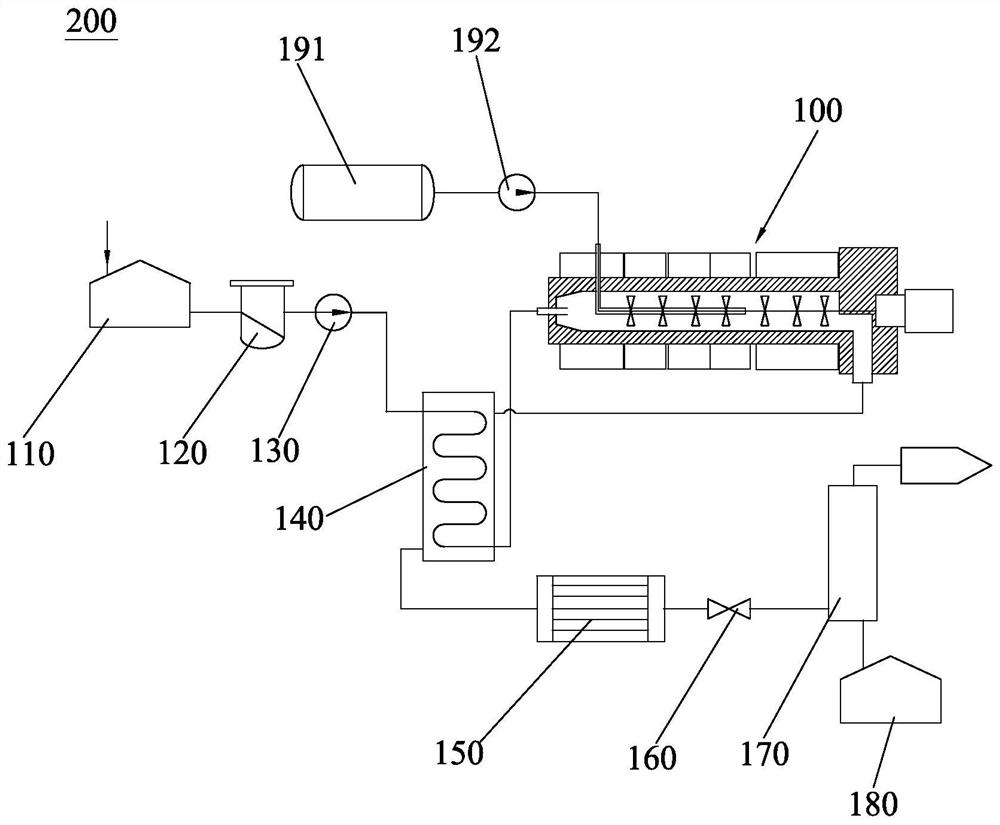

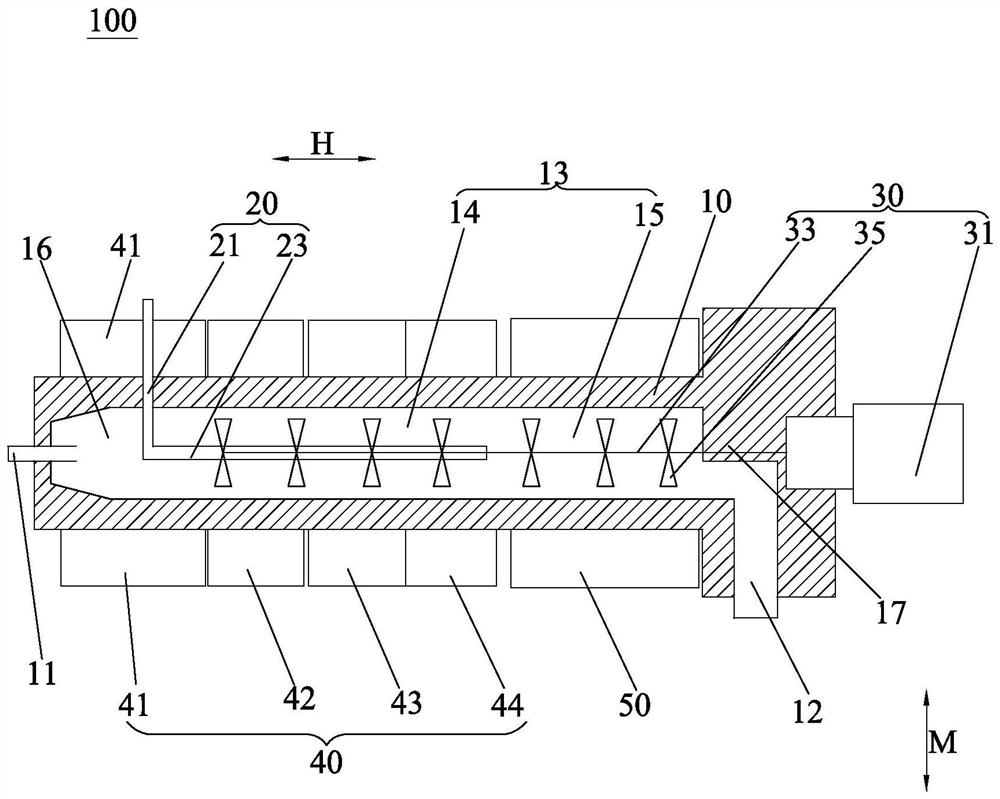

[0024] Please refer to Figure 1-Figure 2 , The supercritical water oxidation system 200 of the present application includes a supercritical water oxidation reactor 100, a feed liquid temporary storage tank 110 connected in sequence, a filter 120, a high-pressure plunger pump 130, a heat exchanger 140, a condenser 150, a back pressure Valve 160, gas-water separator 170 and inorganic waste liquid tank 180, gas-water separator 170 includes a pipeline and a shell side, the outlet of the pipeline is connected to the feed liquid inlet 11, the feed liquid outlet 12 is connected to the inlet of the shell side, and the shell side The outlet communicates with the condenser 150 . Specifically, the organic waste liquid to be treated and the soft water are firstly mixed in a material liquid temporary storage tank 110 according to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com