Character erasing device for license plate manufacturing

A technology for license plates and mounting plates, which is applied in the direction of grinding drive devices, manufacturing tools, grinding workpiece supports, etc., can solve the problems of manpower consumption, low work efficiency, cumbersome operation process, etc., and achieve improved work efficiency, simple operation, and saving human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

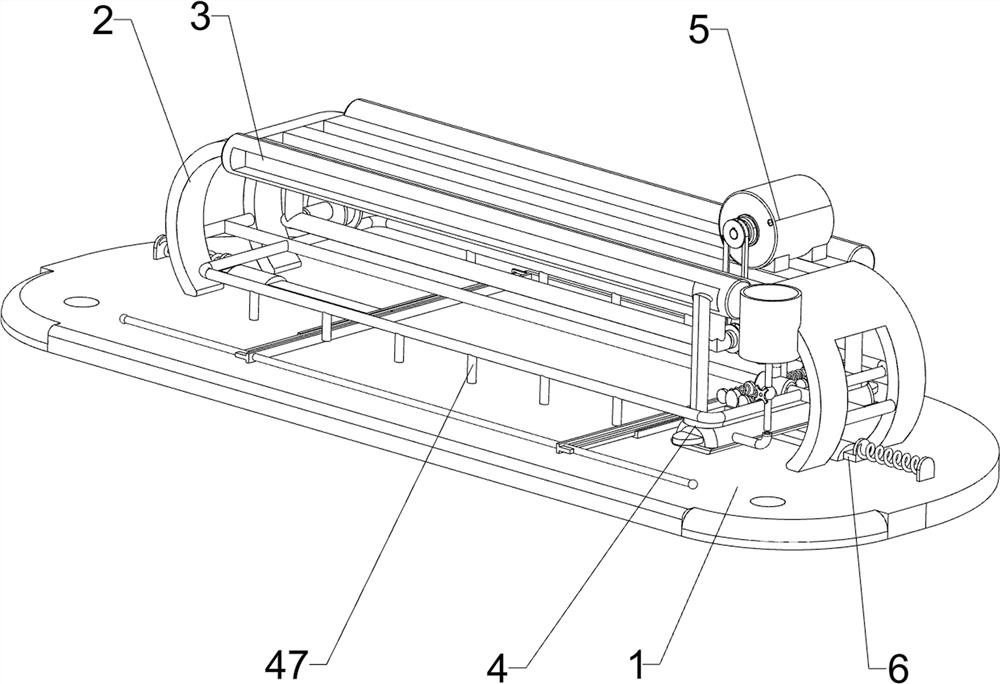

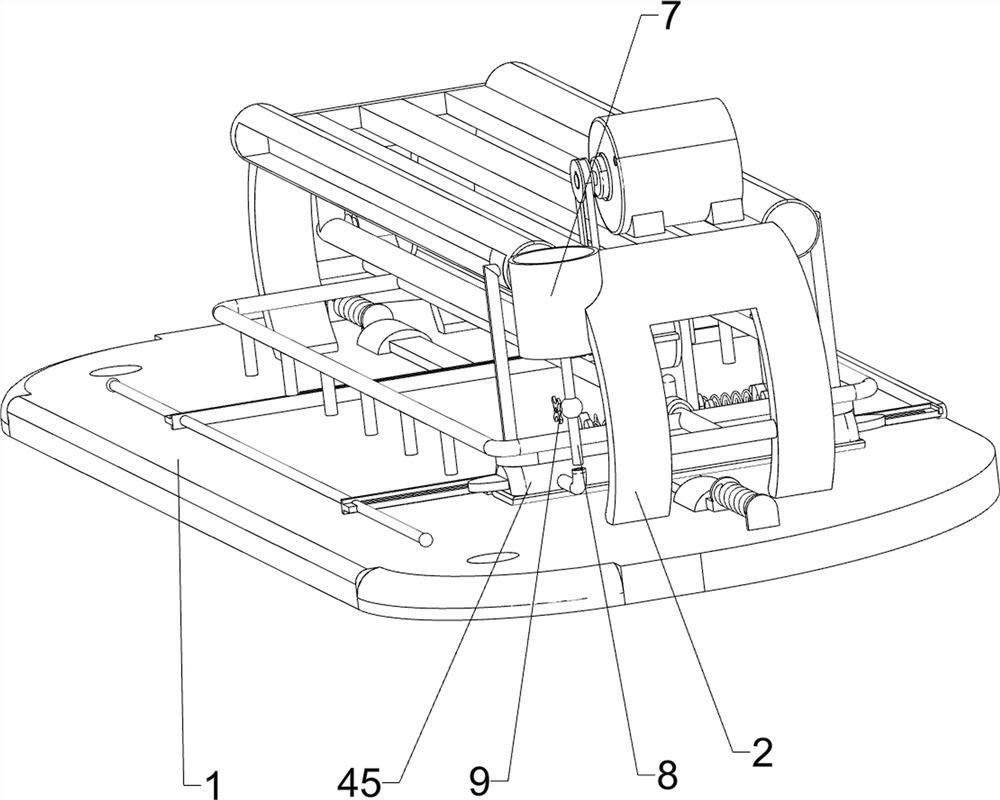

[0025] A word erasing device for license plate production, such as Figure 1-2 As shown, it includes a chassis 1, a mounting plate 2, and a guide rail 3. The top of the chassis 1 is connected to the mounting plate 2, and the front and rear sides of the mounting plate 2 are connected to the guide rails 3. It also includes a friction mechanism 4 and a transmission mechanism 5. The mounting plate 2 A friction mechanism 4 is provided between the guide rail 3 , and a transmission mechanism 5 is provided on the mounting plate 2 , and the transmission mechanism 5 and the friction mechanism 4 are connected in transmission.

[0026] The friction mechanism 4 includes a slide bar 41, a base plate 42, a cross bar 43, a sleeve pipe 44, a wiper block 45, a back-moving spring 46, a push rod 47 and a wedge block 48, and the slide bar 41 is slidably connected on the guide rail 3, and both sides slide A base plate 42 is connected between the bottoms of the rods 41, a cross bar 43 is connected t...

Embodiment 2

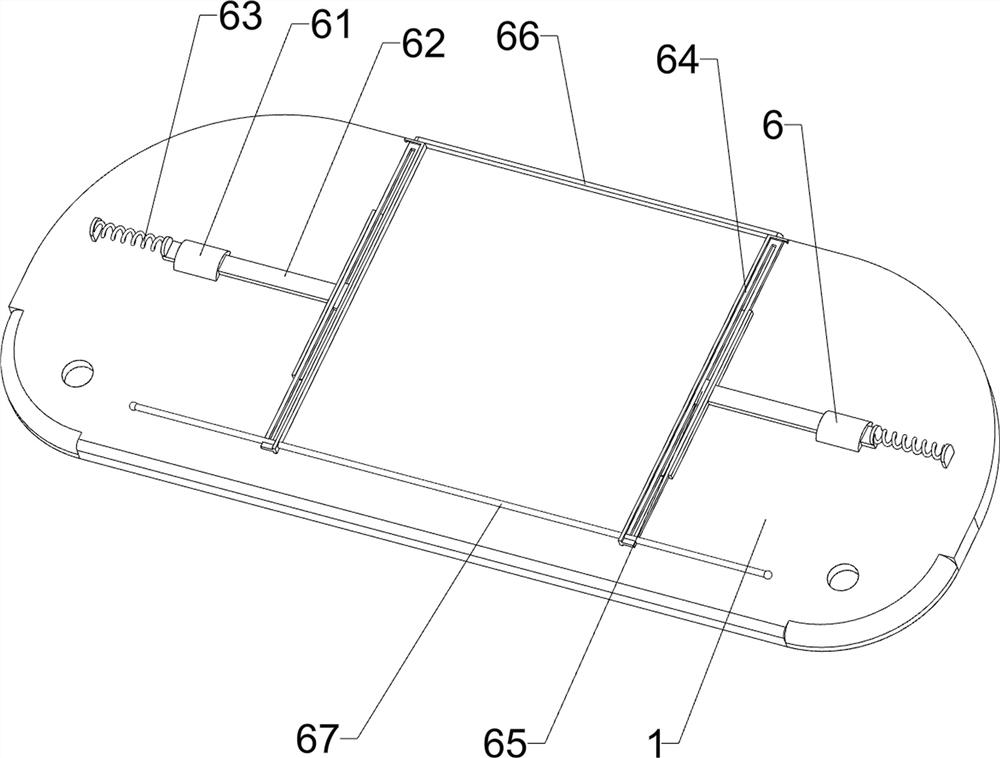

[0030] On the basis of Example 1, such as image 3 As shown, a clamping mechanism 6 is also included. The clamping mechanism 6 includes a sliding sleeve 61, a T-shaped slide plate 62, a pressure spring 63, a counter plate 64, a limit block 65, a baffle plate 66 and a pull rod 67. The left and right sides of the top of the chassis 1 Sliding sleeves 61 are connected to both sides, and a T-shaped slide plate 62 is slidably connected to the inside of the slide sleeve 61. A pressure spring 63 is connected between the T-shaped slide plate 62 and the chassis 1, and the sides of the T-shaped slide plates 62 on both sides slide. The T-shaped slide plate 62 is connected with a limit block 65, and the limit block 65 is used to limit the position of the support plate 64. A pull rod 67 is connected between the front sides of the two support plates 64, and the two sides of the support plates Baffle plate 66 is connected between 64 rear sides.

[0031] When placing the license plate, you ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com