Sizing agent, reinforcing fiber bundle, fiber-reinforced resin forming material, and fiber-reinforced composite material

A technology of reinforcing fiber and sizing agent, applied in the direction of epoxy resin coating, carbon fiber, fiber treatment, etc., can solve the problem that the split tow is not fully integrated, and achieve the effect of excellent cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

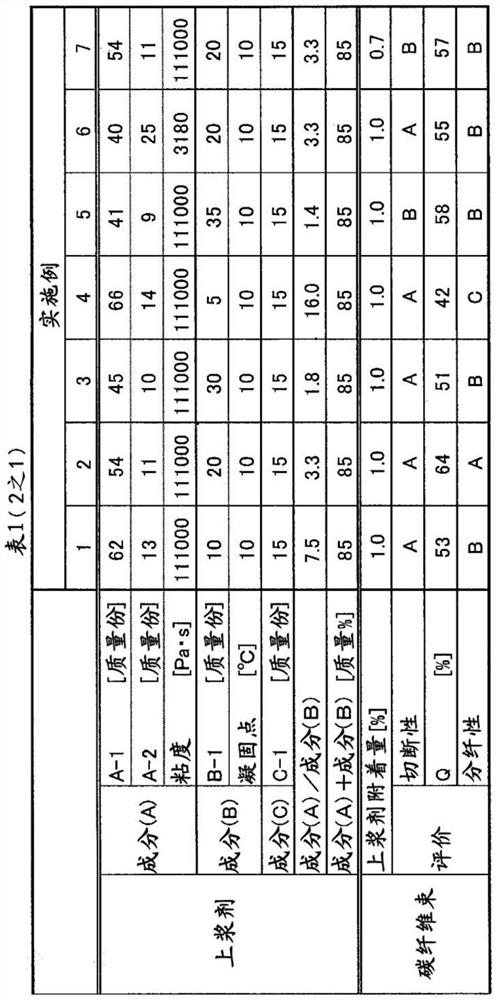

Embodiment 1

[0172]

[0173] Will be mixed with the epoxy resin of the component (A-1) 62 mass parts and component (A-2) 13 mass parts as component (A), component (B-1) 10 mass parts and surfactant (C-1 ) 15 parts by mass were mixed to obtain a sizing agent. Ion-exchanged water was added to the above-mentioned sizing agent, and an aqueous dispersion having a concentration of the sizing agent of 30% by mass was prepared by phase inversion emulsification using a homomixer.

[0174]

[0175] The acrylonitrile-based copolymer was wet spun to obtain a carbon fiber bundle precursor having 3,000 filaments and a total fineness of 3,600 tex, and 5 bundles of the carbon fiber bundle precursor were bundled and wound on a bobbin. The bundled carbon fiber bundle precursor was fired to obtain a carbon fiber bundle including 5 individual tows, a total number of filaments of 15,000, and a total fineness of 1,000 tex. Next, the carbon fiber bundle was electrolytically oxidized using ammonium bicarbona...

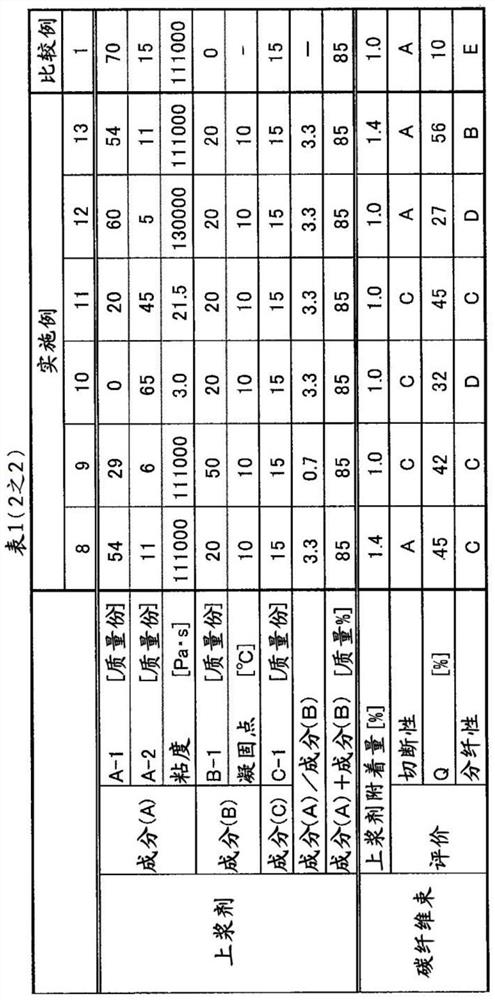

Embodiment 2~12

[0177] Except having changed the composition of a sizing agent and the adhesion amount of a sizing agent as shown in Table 1, it carried out similarly to Example 1, and produced the carbon fiber bundle with a sizing agent. The adhesion amount of the sizing agent is adjusted by adjusting the concentration of the sizing agent in the aqueous dispersion.

Embodiment 13

[0179] A carbon fiber bundle (trade name "TR50S 15L", manufactured by Mitsubishi Chemical Corporation) was used as a continuous fiber bundle. The carbon fiber bundle was intermittently divided so that the length of the undivided part between adjacent sub-filament bundles was 16 mm, and a carbon fiber bundle including 5 sub-bundles with a total filament number of 15,000 and a total fineness of 1,000 tex was obtained. Next, it carried out similarly to Example 2, and produced the carbon fiber bundle with a sizing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com