PCB based on anti-collision protection, and rapid assembling method thereof

A PCB board and assembly method technology, which is applied in the direction of assembling printed circuits, printed circuit components, and electrical components with electrical components, can solve problems such as server board installation collisions, avoid mutual interference, and facilitate stable work. Ensure the effect of signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

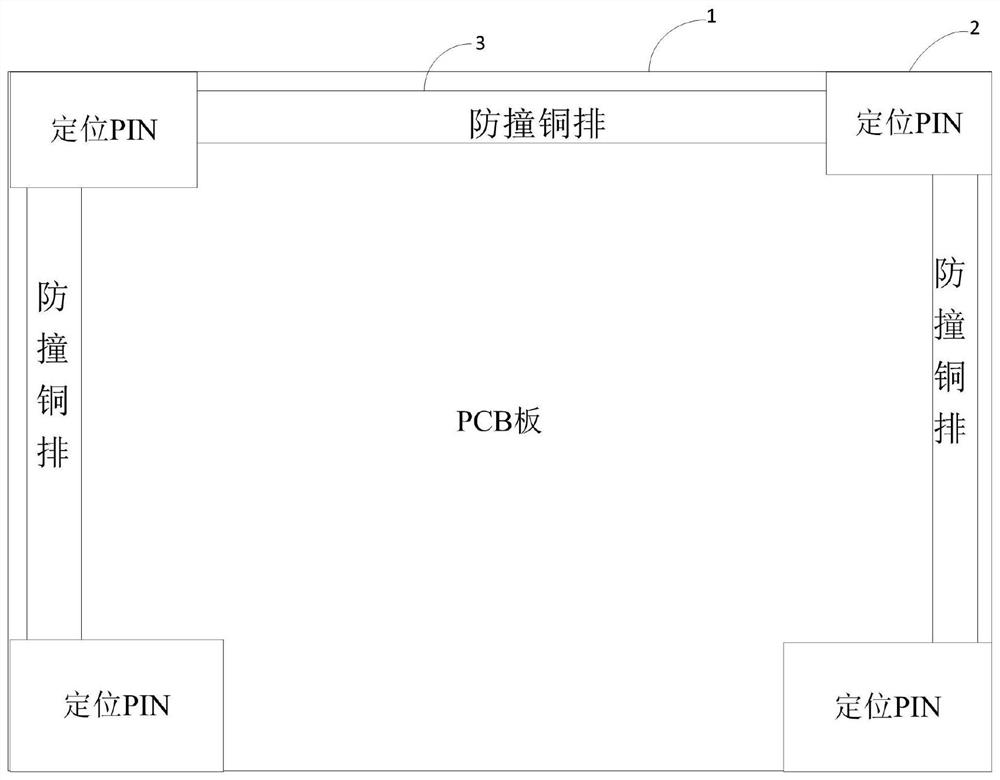

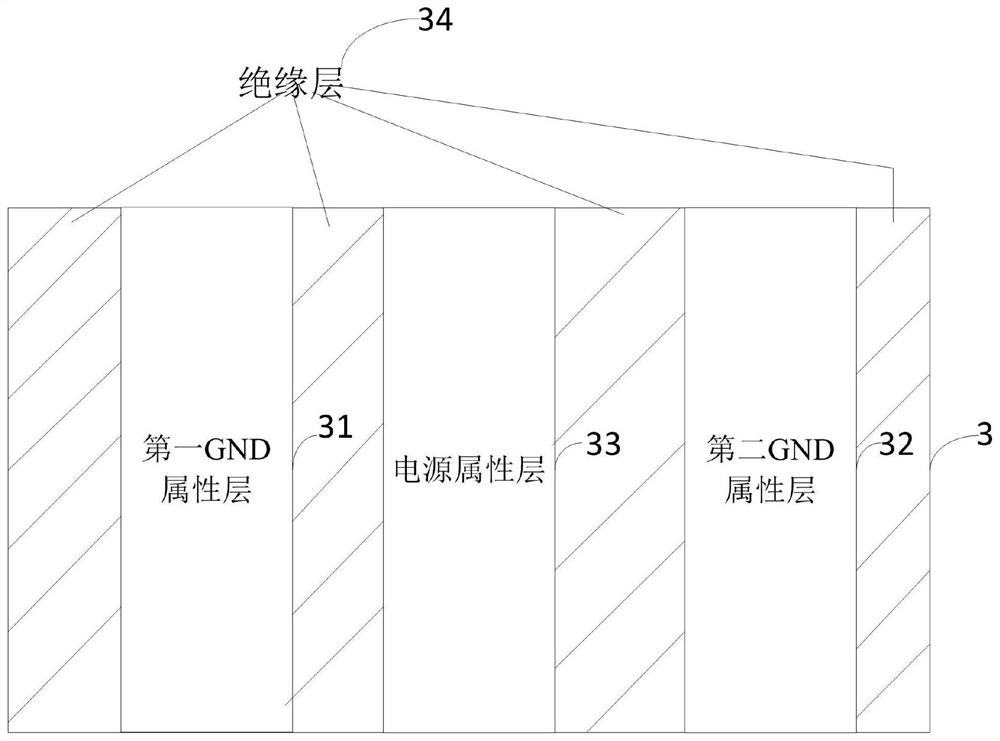

[0037] Such as Figure 1-Figure 2 As shown, the present invention provides a PCB board based on anti-collision protection, which is applied to server boards and includes: PCB board 1, positioning PIN2, anti-collision copper bar 3, positioning PIN2 and anti-collision copper bar 3 are all arranged on At the edge of the PCB board 1 to be protected against collisions, the anti-collision copper bar 3 is connected through the positioning PIN2. The anti-collision copper bar 3 includes a first GND attribute layer 31, a second GND attribute layer 32, a power attribute layer 33, and the first GND attribute layer 32. The attribute layer 31 is located on the top layer of the anti-collision copper bar 3, the second GND attribute layer 32 is located on the bottom layer of the anti-collision copper bar 3, and the power attribute layer 33 is located on the middle layer of the anti-collision copper bar 3, which is used to prevent the components on the PCB board 1 from colliding. , and supply p...

Embodiment 2

[0052] Such as Figure 7 As shown, the technical solution of the present invention also provides a method for quickly assembling PCB boards based on anti-collision protection, which is realized on the basis of Embodiment 1, including:

[0053] S1, set several positioning PINs during PCB board design;

[0054] S2, after the production of PCBA (Printed Circuit Board Assembly, PCB empty board through the upper part, or through the entire process of plug-in), on the edge of the PCB board to be protected against collision, pass a number of anti-collision copper bars through the positioning PIN The mounting holes in the device are connected to the pre-set positioning PIN.

[0055] Wherein, the anti-collision copper bar includes a first GND attribute layer, a second GND attribute layer, and a power source attribute layer. The attribute layer is located in the middle layer of the anti-collision copper bar.

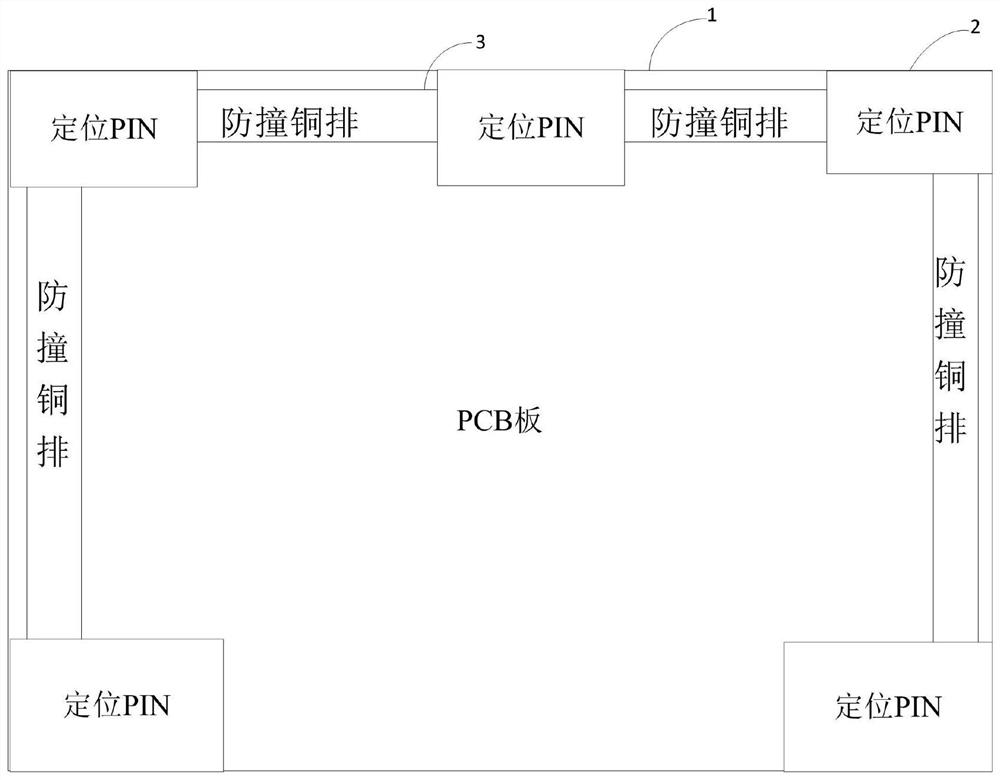

[0056] Further, when the PCB is a plurality of assembled boards, the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com