Composite flanging mechanism of stamping die

A stamping die and flanging technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing mold development and equipment purchase costs, repeating operation steps, and affecting production efficiency, so as to reduce repeated installation and Effects of operation steps, reduction of manufacturing cost, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

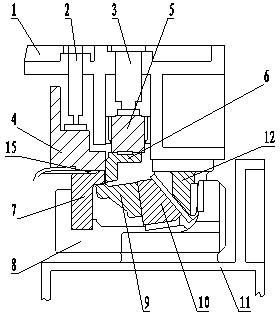

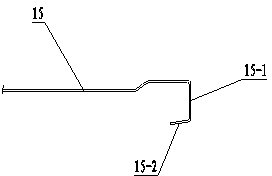

[0018] Referring to Fig. 1, the present invention comprises a vertical flanging part, a side flanging part, a pressing device, an upper mold base 1 and a lower mold base 11, and its special feature is that the vertical flanging and side flanging molds are combined in Together, they share a set of pressing device, and the vertical flange part is arranged between the pressing device and the side flange part.

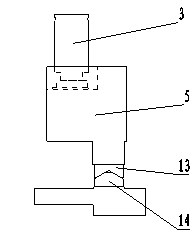

[0019] see figure 1 , figure 2 , the vertical flanging part in the composition of the present invention comprises a small binder core nitrogen spring 3, a small binder core 5, a vertical flanging insert 6, a concave balance weight 13 and a convex balance weight 14, and the small binder core nitrogen spring 3. The upper end is fixed on the upper mold base 1 of the mold, and the lower end is fixedly connected with the small binder core 5, and the top of the small binder core 5 is fixedly connected with the vertical flanging insert 6. A concave balance weight 13 matched wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com