Wiring method for erecting all-dielectric self-supporting optical cable based on double angle steel main material iron tower

A self-supporting optical cable, all-dielectric technology, applied in the direction of optical fiber/cable installation, tower, building type, etc., to achieve the effect of high precision, stable method, smooth operation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

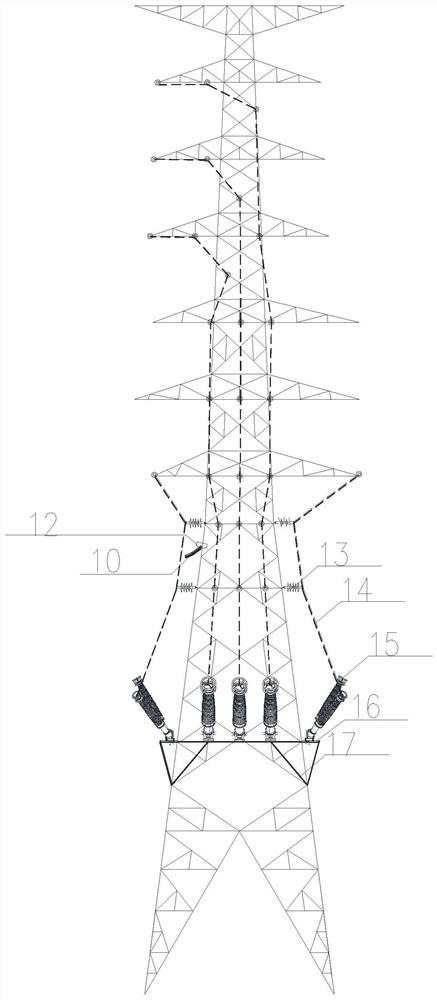

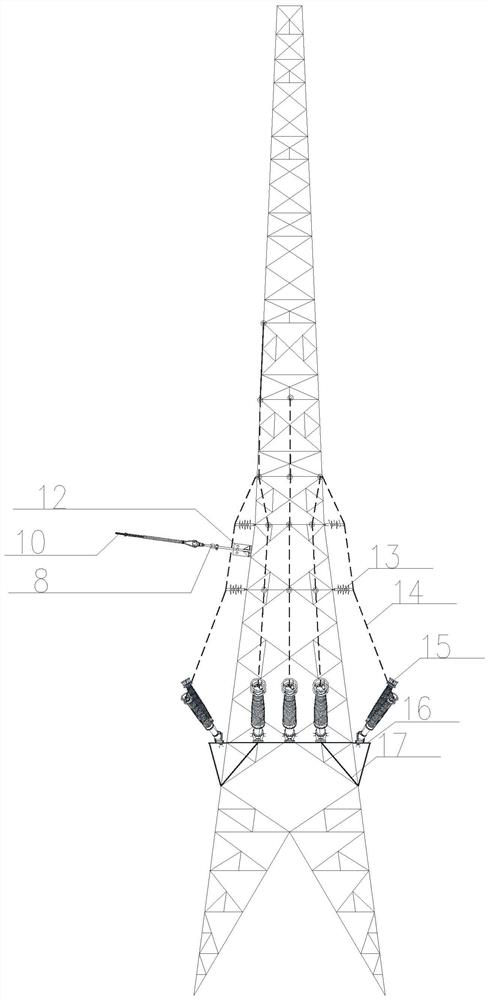

[0042] The present invention will be further described below with reference to the accompanying drawings.

[0043] see Figure 1 to Figure 4 As shown, the present invention provides an embodiment: a method for erecting an all-dielectric self-supporting optical cable based on a double angle steel main material iron tower includes the following steps:

[0044] Step S1, selecting the hanging point position of the all-dielectric self-supporting optical cable 10 according to the distribution of the electromagnetic field intensity and the distribution position of the cable drain wire 14;

[0045] Step S2, by selecting the special ADSS splint 12 of the cross-type double-joint angle steel main material iron tower, it is used for the hanging of the tower body double-joint angle steel main material 9 below the lower rung, thereby solving ADSS in the cross-type double-joint angle steel main material iron tower the hanging problem;

[0046] Step S3, hanging the all-dielectric self-suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com