Paper inserting machine of card issuing motor iron core

A paper inserter and iron core technology, applied in the direction of laying solid insulation, etc., can solve the problems of blocking the embedding groove, bending or wrinkling of insulating paper, etc., and achieve the effect of avoiding deformation, solving bending deformation or wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

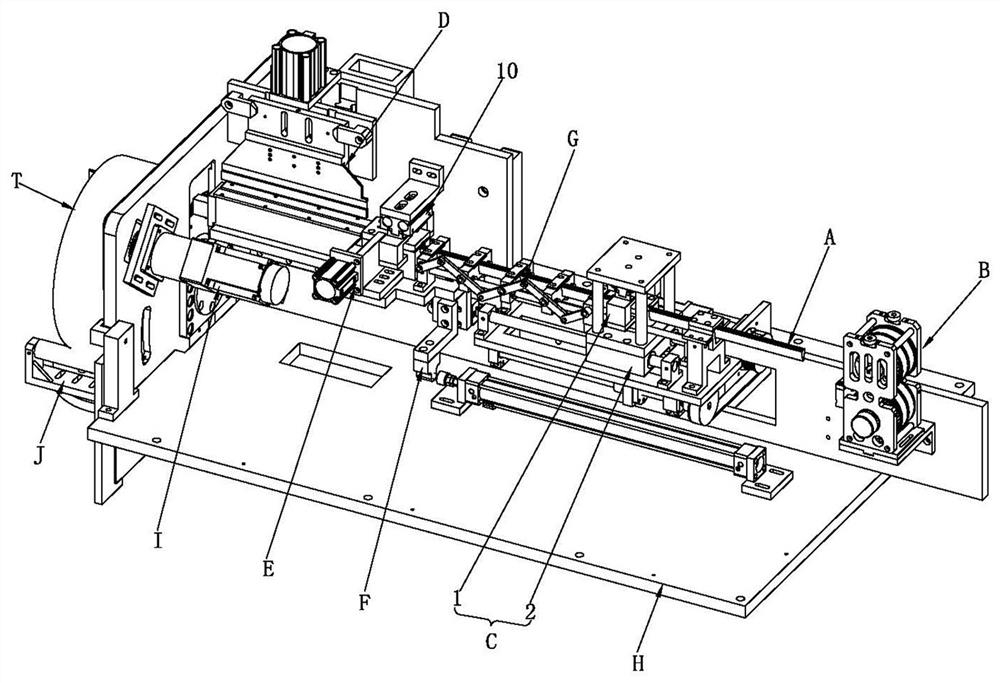

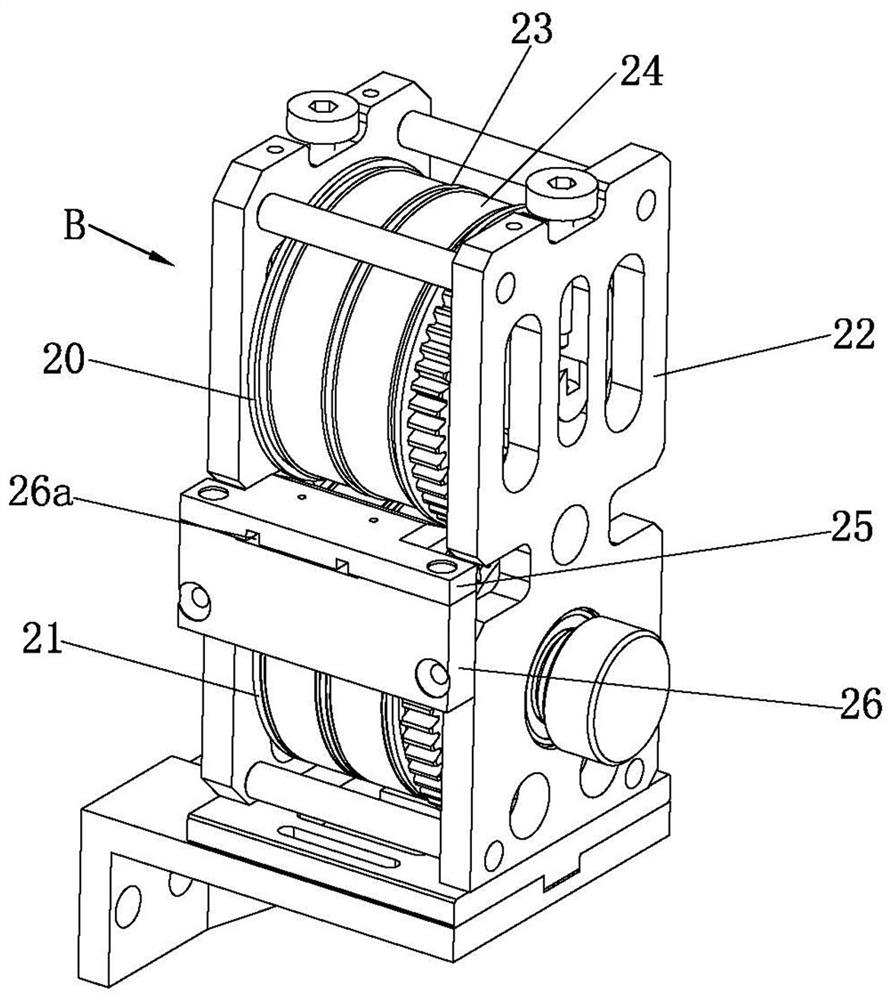

[0028] like figure 1 and figure 2 The paper inserting machine for the iron core of the card issuing motor shown in this embodiment is used for inserting insulating paper into the iron core of the card issuing motor stator, for example. In this embodiment, the paper inserting machine for the iron core of the card-generating motor includes a paper folding mechanism B, a paper feeding mechanism C, a forming mechanism D, a paper cutting mechanism E, and a paper pushing mechanism F. The paper folding mechanism B makes the insulating paper passing through the paper folding mechanism B Creases are formed on the surface of A. The forming mechanism D shapes the insulating paper A into a shape that matches the wire groove of the iron core T. The paper cutting mechanism E is located between the paper feeding mechanism C and the forming mechanism D and is used to cut the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com