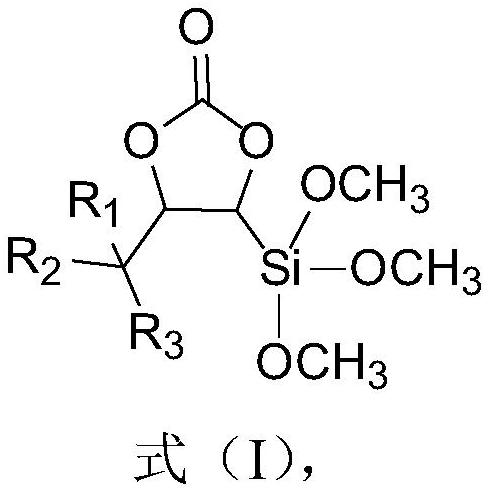

High-voltage additive as well as preparation method and application thereof

A high-voltage, additive technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as increasing electrode interface impedance, and achieve the effects of good water removal, excellent performance, and good high-voltage resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

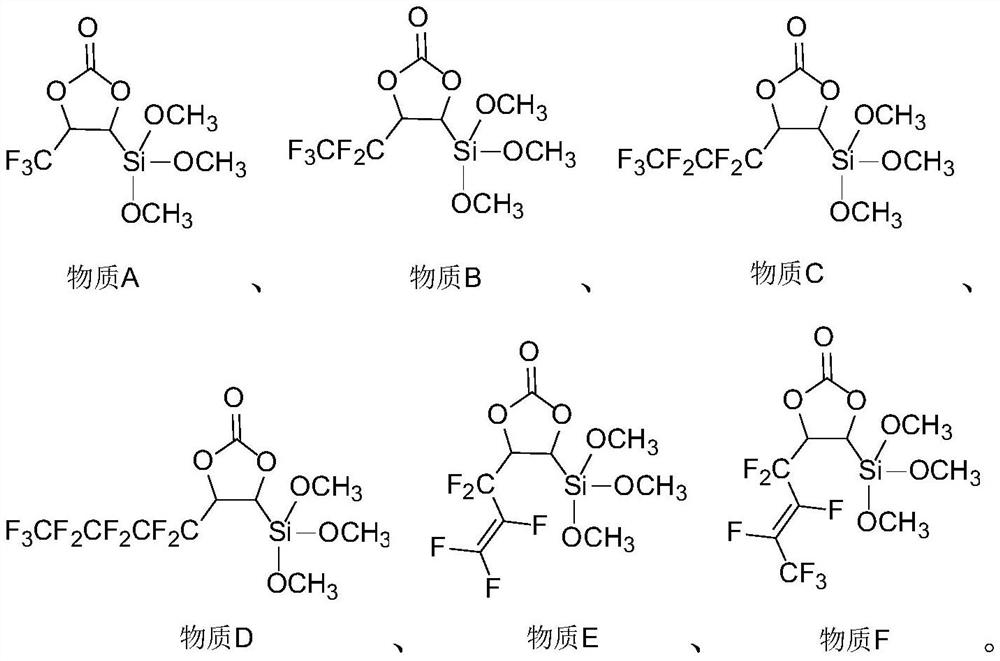

[0037] The preparation method of substance A, comprises the steps:

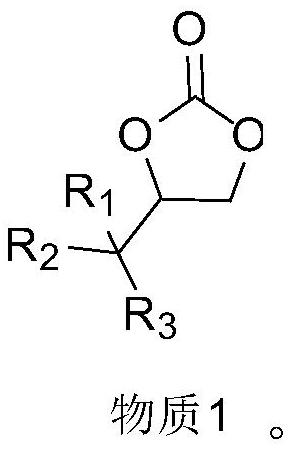

[0038] Dissolve 20g of 4-methylethylene carbonate (that is, substance 2) in 100ml of tetraethylene glycol dimethyl ether, control the temperature at 35°C, slowly add potassium fluoride and stir for 6 hours, take the reaction liquid and distill it under reduced pressure to obtain about 15g 4-trifluoromethylethylene carbonate (i.e. Substance 1);

[0039] Mix 30g of trimethylchlorosilane, 10g of 4-trifluoromethylethylene carbonate, and 10ml of tetrahydrofuran, and react under reflux at 60°C for 10h, take the reaction liquid and undergo rectification three times, and collect fractions with a rectification temperature of 180-200°C , which is substance A, and its purity reaches above 96.5%.

Embodiment 2

[0041] The preparation method of substance B: replace 4-methyl ethylene carbonate with 4-ethyl ethylene carbonate, collect the distillate with a rectification temperature of 200-220° C. to be substance B, and the others are the same as in Example 1.

Embodiment 3

[0043] The preparation method of substance C: replace 4-methyl ethylene carbonate with 4-propyl ethylene carbonate, collect the fraction with a rectification temperature of 190-230° C. to be substance C, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com