Movable physicochemical inspection and analysis test bed

An inspection and analysis, test-bed technology, applied in the field of physical and chemical inspection and analysis, can solve the problems of power line collision or external force pulling, power line and circuit board damage, small operating space, etc., to achieve easy maintenance, simple structure, and locking effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

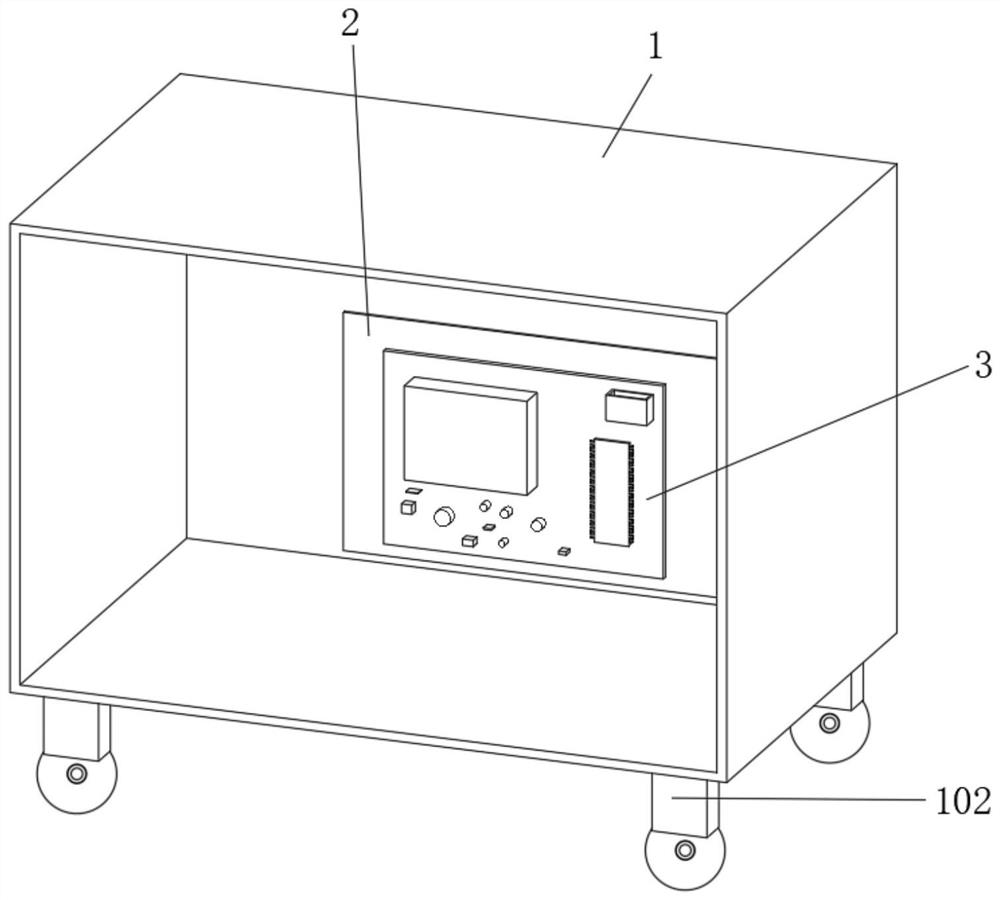

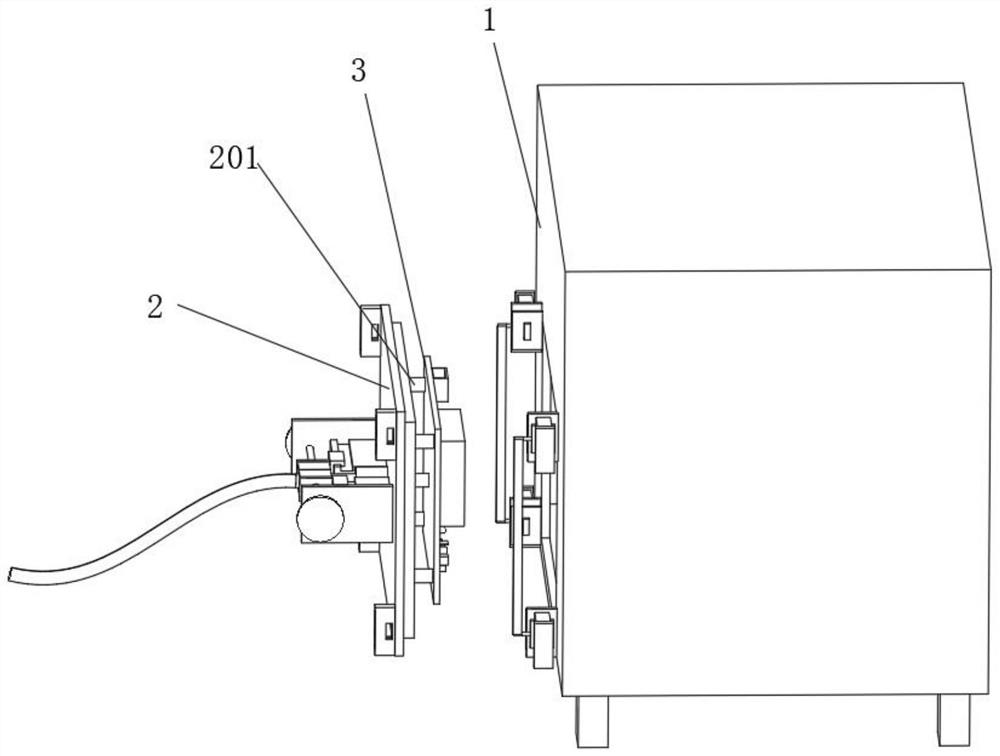

[0031] Embodiments of the present invention provide a mobile physical and chemical inspection and analysis test bench, such as Figure 1-8As shown, it includes the bottom shell 1 of the test bench and the load-bearing mounting plate 2. The back of the bottom shell 1 of the test bench is provided with a backplane opening 101 corresponding to the load-bearing mounting plate 2. The bottom four corners of the bottom shell 1 of the test bench are The universal wheel 102 is fixedly installed at the place, and the front of the load-bearing installation plate 2 is fixedly connected with four sets of fixed columns 201. When it is on the backplane opening 101, the main board main body 3 is located in the inner cavity of the bottom shell 1 of the test bench, and the back of the main board main body 3 is fixedly connected with a connecting wire 301, and the end of the connecting wire 301 away from the main board main body 3 passes through the load-bearing mounting plate 2 and extend outwa...

Embodiment 2

[0036] Embodiments of the present invention provide a mobile physical and chemical inspection and analysis test bench, such as Figure 1-8 As shown, it includes the bottom shell 1 of the test bench and the load-bearing mounting plate 2. The back of the bottom shell 1 of the test bench is provided with a backplane opening 101 corresponding to the load-bearing mounting plate 2. The bottom four corners of the bottom shell 1 of the test bench are The universal wheel 102 is fixedly installed at the place, and the front of the load-bearing installation plate 2 is fixedly connected with four sets of fixed columns 201. When it is on the backplane opening 101, the main board main body 3 is located in the inner cavity of the bottom shell 1 of the test bench, and the back of the main board main body 3 is fixedly connected with a connecting wire 301, and the end of the connecting wire 301 away from the main board main body 3 passes through the load-bearing mounting plate 2 and extend outw...

Embodiment 3

[0043] Embodiments of the present invention provide a mobile physical and chemical inspection and analysis test bench, such as Figure 1-8 As shown, it includes the bottom shell 1 of the test bench and the load-bearing mounting plate 2. The back of the bottom shell 1 of the test bench is provided with a backplane opening 101 corresponding to the load-bearing mounting plate 2. The bottom four corners of the bottom shell 1 of the test bench are The universal wheel 102 is fixedly installed at the place, and the front of the load-bearing installation plate 2 is fixedly connected with four sets of fixed columns 201. When it is on the backplane opening 101, the main board main body 3 is located in the inner cavity of the bottom shell 1 of the test bench, and the back of the main board main body 3 is fixedly connected with a connecting wire 301, and the end of the connecting wire 301 away from the main board main body 3 passes through the load-bearing mounting plate 2 and extend outw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com