Dewatering and drying device for sludge treatment

A drying device and sludge treatment technology, applied in the direction of sludge drying, heating devices, drying solid materials, etc., can solve the problems of uneven heating of sludge, reduce drying effect, affect dehydration effect, etc., to increase practical performance and application flexibility, ensuring efficiency and quality, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

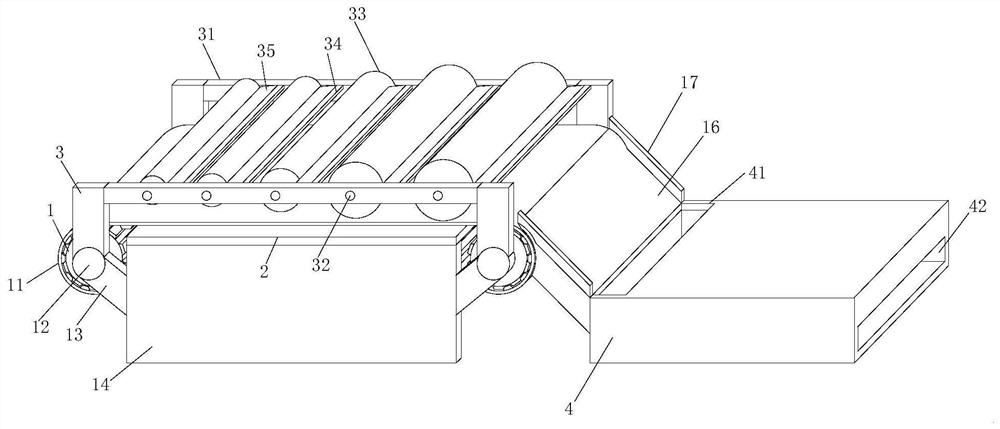

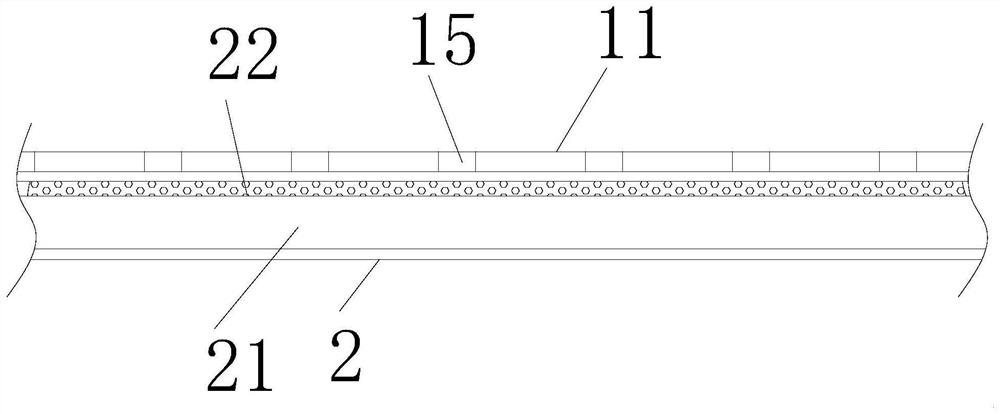

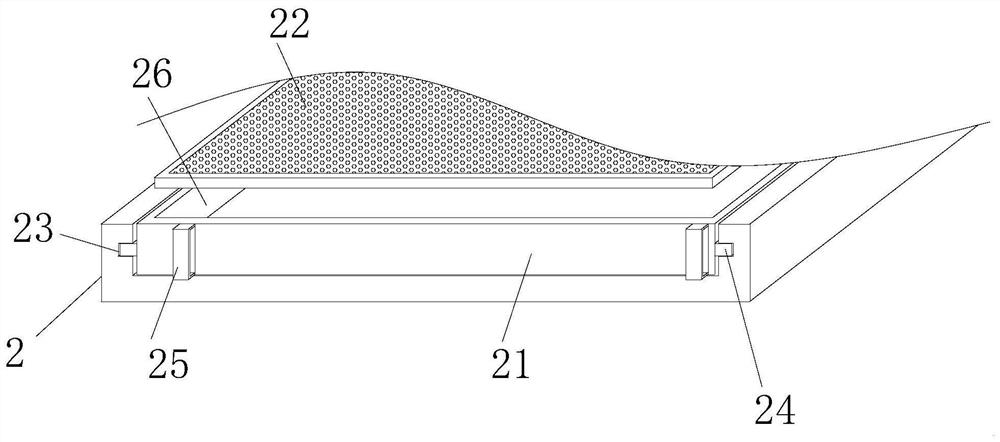

[0027] Such as Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: a dehydration and drying device for sludge treatment, including a conveyor belt 1, a support plate 14 is set up on both sides of the middle of the conveyor belt 1, and a storage platform 2 is connected to the top of the support plate 14, One end of the conveyor belt 1 is provided with a dryer 4, the inside of the dryer 4 is connected with a baking plate 462, and a plurality of pressing rollers 33 are provided above the conveyor belt 1;

[0028] There are multiple pressing rollers 33, and the two ends of each pressing roller 33 are fixedly connected with a rotating shaft 32, and the rotating shaft 32 is rotatably connected with a crossbeam 31. One side of each pressing roller 33 is equipped with a scraper 35, and the scraper 35 One end is fixedly connected with a fixed plate 34, and the fixed plate 34 is fixedly connected to the opposite side walls of the two beams 31 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com