Low-filtration-loss long-seam forming clean fracturing process

A technology of clean fracturing and clean fracturing fluid, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of restricting the popularization and application of clean fracturing fluid, poor reusability of fracturing flowback fluid, Clean the problems of fracturing fluid such as large filtration loss, achieve good sand-carrying performance, good temperature resistance and shear resistance, and reduce reservoir damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A clean fracturing process for long fractures with low fluid loss. The process combines weakly acidic clean fracturing fluid with high-efficiency fluid loss reducer, and uses high-efficiency fluid loss reducer to reduce the filtration rate of weakly acidic clean fracturing fluid in the reservoir. It improves the fracture creation performance of weakly acidic clean fracturing fluid and realizes the creation of fractures.

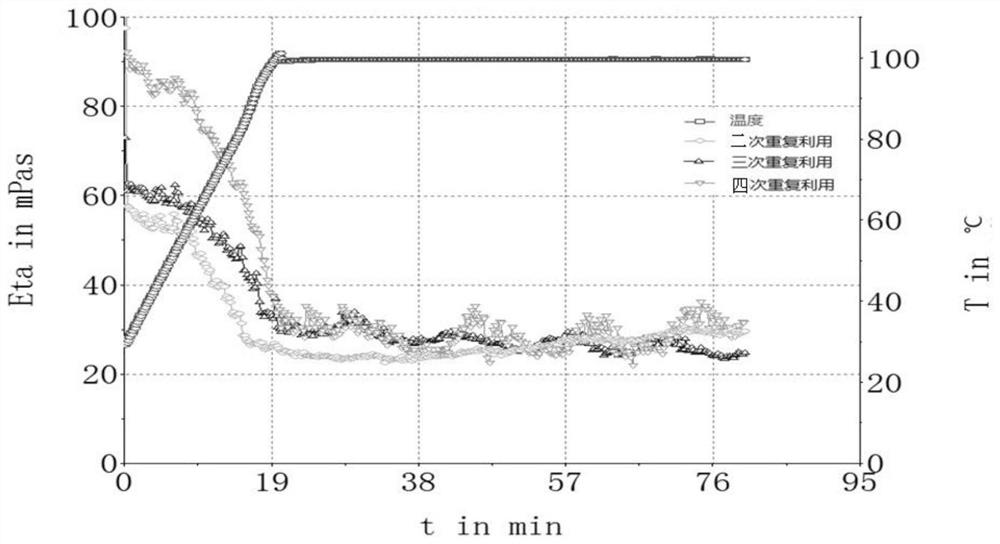

[0025] The weakly acidic clean fracturing fluid used in the process of the present invention has the characteristics of low residue, low damage, good temperature resistance, shear resistance, and sand-carrying performance, and can be ready-to-use on site and continuously mixed. The combination of clean fracturing fluid and a new high-efficiency fluid loss reducer greatly reduces the fluid loss of the clean fracturing fluid and improves its fracture-making performance, forming a system that can effectively reduce the In addition, it can reduce the fluid...

Embodiment 2

[0027] Further, a low fluid loss long fracture clean fracturing process, the construction process of the process at least includes the following stages:

[0028] In the first stage, a small amount of weakly acidic clean fracturing fluid is first pumped to increase the displacement, and at the same time, the formation is fractured to form certain initial fractures. After the fractures are opened, high-efficiency fluid loss additives are added at a mass rate of 0.1%-1.0% Compared with the addition of high-efficiency fluid loss reducer (the better the porosity and permeability of the reservoir, the higher the addition ratio), the liquid volume in the first stage of the special reservoir that is difficult to press open should not be lower than the displacement fluid volume;

[0029] In the second stage, continue to add high-efficiency fluid loss reducer at a ratio of 0.1%-1.0%. At the same time, pump weakly acidic clean fracturing fluid and add 40-70 mesh fine silt or fine Ceramsi...

Embodiment 3

[0055] On the basis of Example 2, preferably, the weakly acidic cleaning fracturing fluid is composed of 3.0% oligoaminosuccinic acid fatty acid fatty acid salt, 2.0% potassium chloride, 0.3% industrial formic acid and 94.7% water according to the above The mass ratio is mixed.

[0056] Preferably, the molecular formula of the oligomeric aminosuccinic acid fatty acid fatty acid salt: (C 7 h 8 o 7 N + NR 2 ) n Cl - , where R is C 12~20 , n is 1-4.

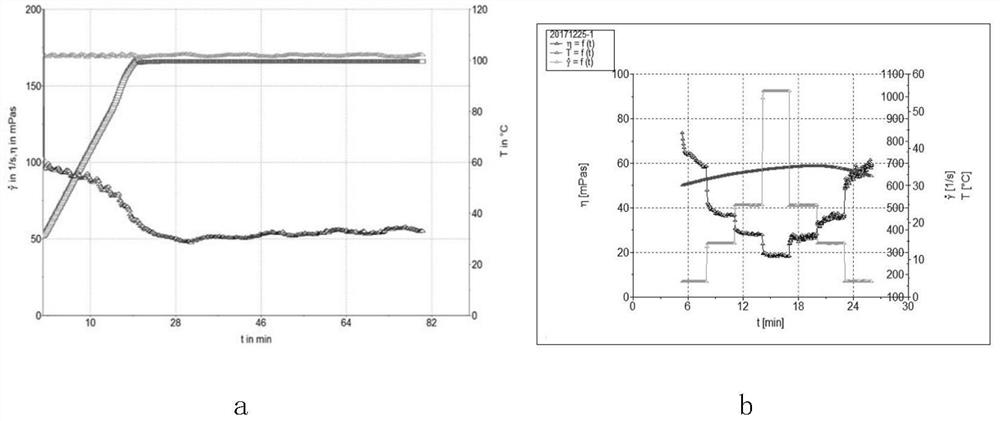

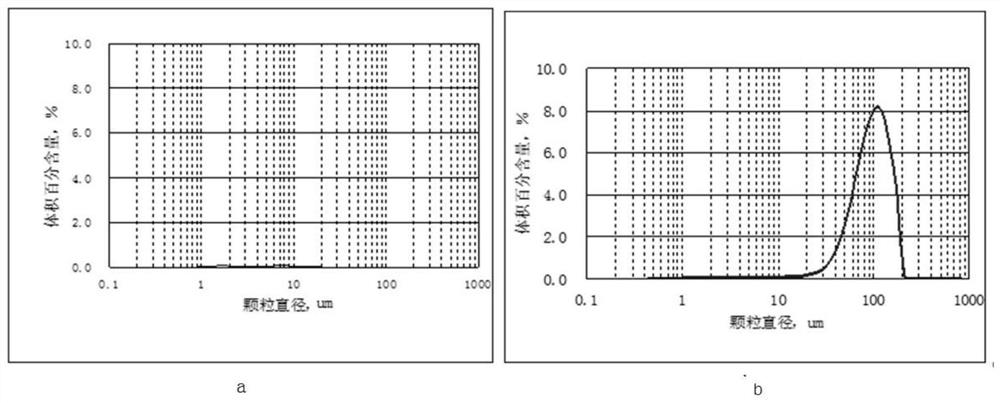

[0057] The weakly acidic clean fracturing fluid has a gel breaking fluid residue content of 0.67mg / L, a resistance reduction rate of ≥70%, and meets the construction requirement of 45% sand ratio. The test data results are as follows:

[0058] (1) Determination of the residue of the gel breaking fluid of this fracturing fluid system. According to the experimental results, when the crude oil is broken at high temperature, the residue content of the gel breaking fluid is 0.67mg / L, which is the residue in the industrial produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com