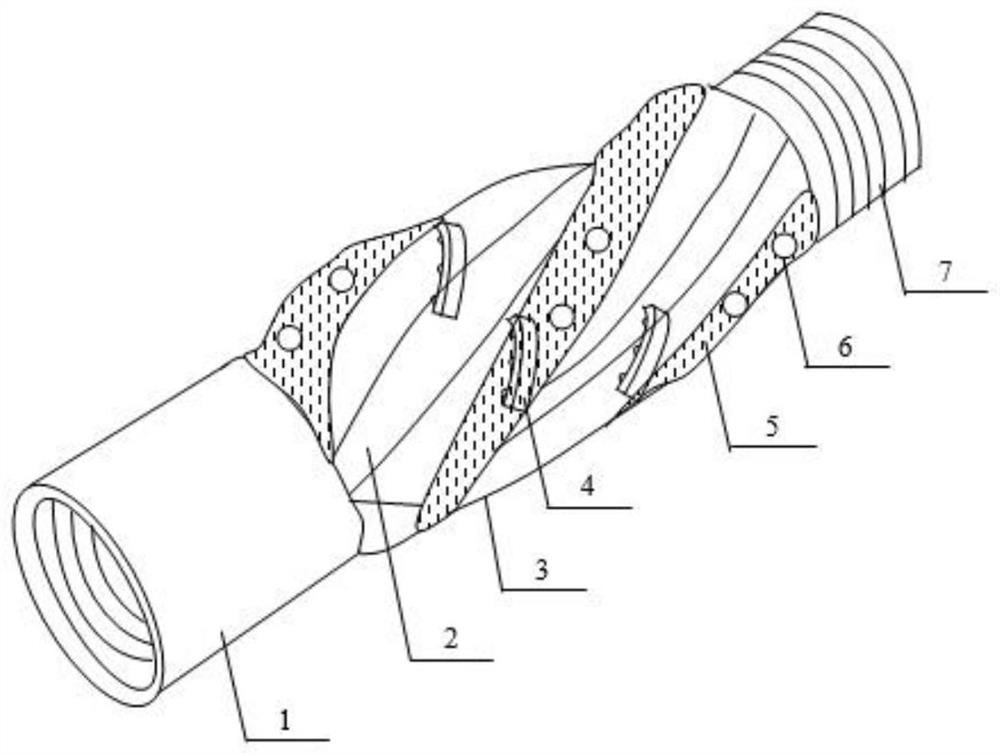

Irregular shaft cleaning and drifting device based on deflection angle flow dividing and drifting method

An irregular, well-passing technology, used in cleaning equipment, wellbore/well components, earth-moving drilling and other directions, can solve the problems of obstruction during tripping, low wellbore cleanliness, etc., and achieve improved and reduced cleanliness. The effect of a collapse accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] (1) WY29-4HF well

[0029] 1) Borehole size: φ311.2mm

[0030] 2) The reason for the irregular well section: 764-986m, the air drilling process was used, and then it was converted to the conventional drilling fluid process. The hole expansion rate caused by the air drilling process was 10% higher than that of the conventional drilling fluid, so a pot belly occurred in this well section borehole. Drilling cuttings accumulate in the belly section, making it difficult to circulate out of the wellbore, which may easily cause downhole complications.

[0031] 3) Well drilling tool assembly: φ311.2mm cone bit + back pressure valve + 1 piece of 203.2mm helical drill collar + well body + 5 pieces of 203.2mm helical drill collar + 15 pieces of 139.7mm heavy drill pipe + 139.7mm drill pole.

[0032] 4) Drilling process: Drill down to the depth of the well, adopt the method of active reaming to the depth of 986m, and circulate the cuttings.

[0033] 5) Condition of the wellbore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com