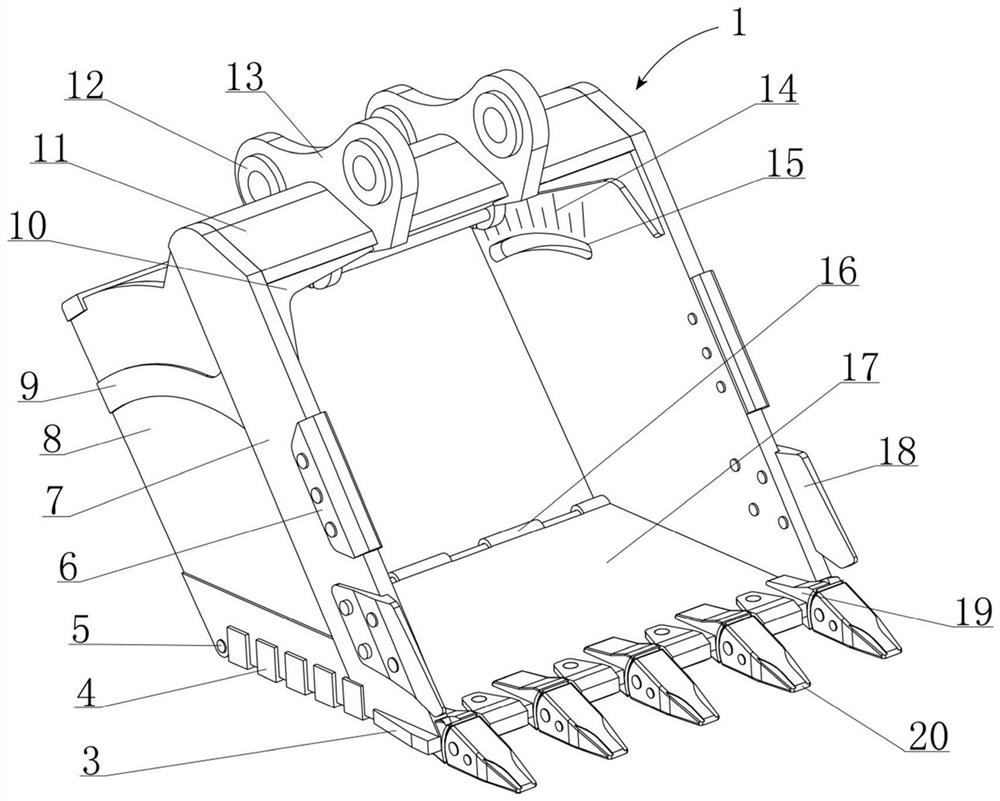

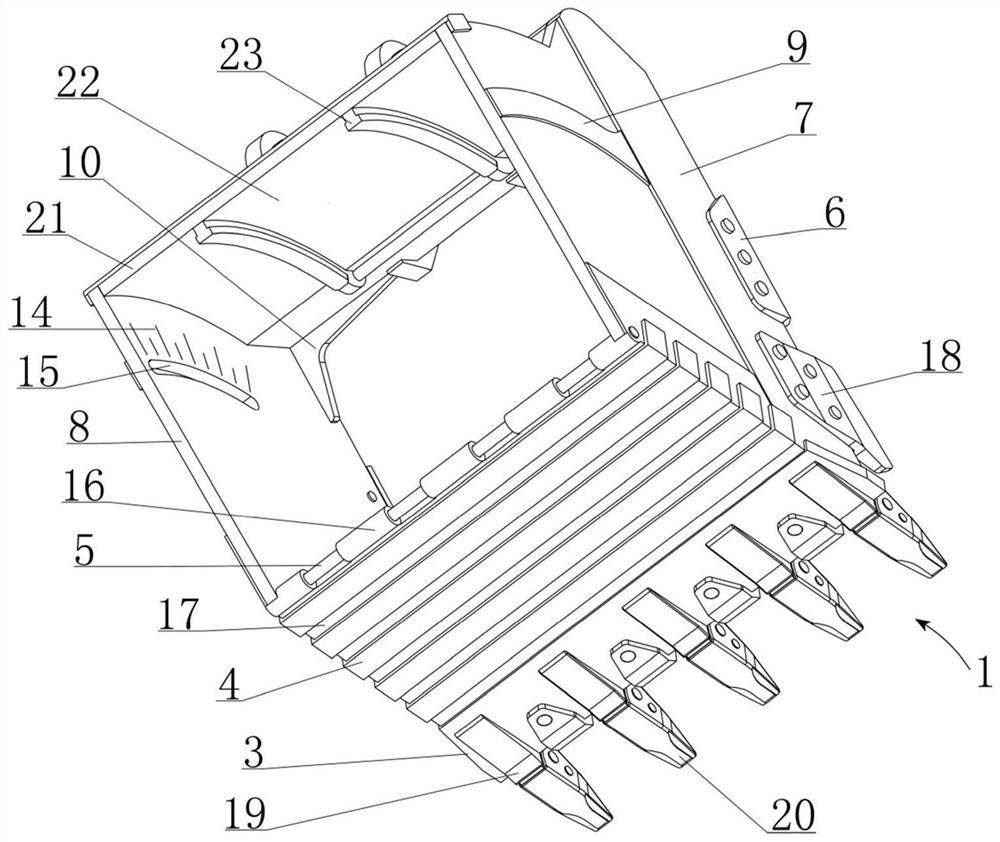

Excavator bucket with adjustable bucket capacity

An excavator technology with adjustable bucket capacity, applied to mechanically driven excavators/dredgers, earth movers/shovelers, construction, etc., can solve the problem of adjusting the bucket capacity to the optimal value, which is not scientific and reasonable, Time-consuming and labor-intensive issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

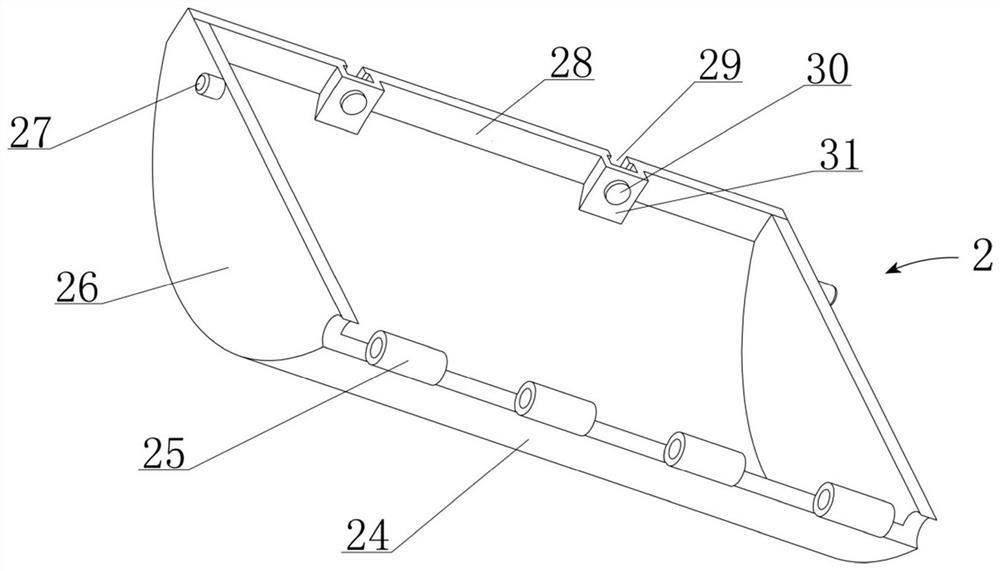

[0049] see Figure 4 , 5 As shown, in the excavator bucket, the locking mechanism can be implemented in a variety of ways. The implementation based on the locking bolt 30 has been listed above, but in practical applications, the locking mechanism provided by the locking bolt 30 The locking effect is not stable enough, and it is necessary to frequently check whether the locking bolt 30 is loose; for this reason, the present invention also provides another embodiment of the locking mechanism, and the specific structure is:

[0050] see Figure 12 , 13 As shown, the guide rail 23 is a T-shaped rail, and the slider 31 is provided with a T-shaped groove 29 matching with the guide rail 23; The tooth groove 36, a tooth plate 39 installed in the slider 31, a locking bolt 37 installed on the slider 31, the bottom of the tooth groove 36 is evenly distributed with positioning teeth 35, the teeth The plate 39 stretches into the tooth groove 36 and is provided with a locking tooth 38 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com