Novel construction concrete pipe pile based on anti-penetration technology and its preparation method

A concrete pipe pile, anti-penetration technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of poor anti-seepage performance, affecting mechanical strength, reducing the bearing strength of pouring earthwork, etc., to improve the overall connection degree , Improve mechanical strength, good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

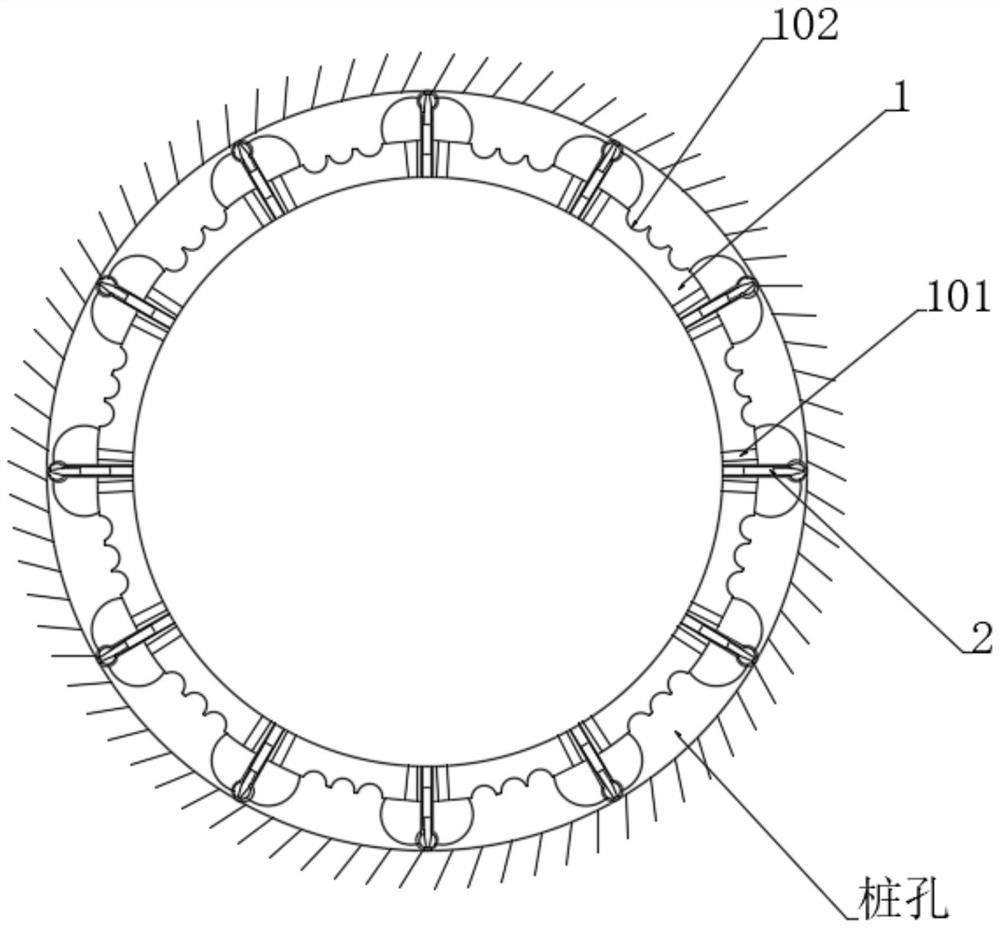

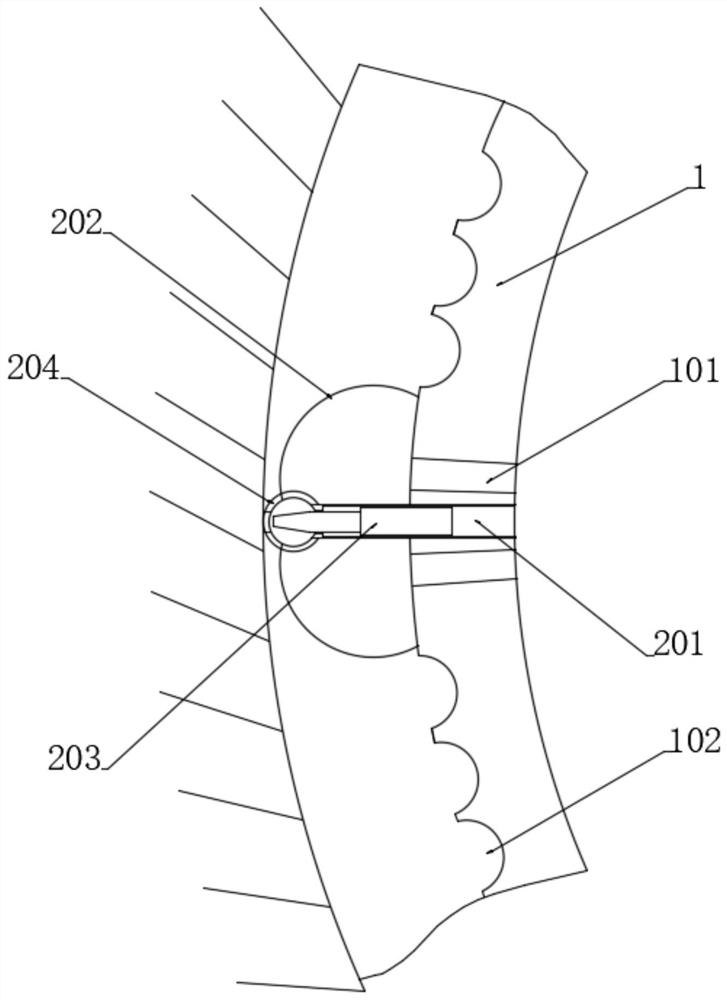

[0044] see Figure 1-4 , a new type of architectural concrete pipe pile based on anti-seepage technology, including a hollow steel bar column 1, a plurality of transverse expansion bodies 2 are annularly distributed on the outer wall of the hollow steel bar column 1, and the inner ends of the transverse expansion bodies 2 are embedded in the hollow steel bar The inner wall of the pipe column 1 communicates with the interior of the hollow reinforced pipe column 1. A plurality of pouring holes 101 corresponding to the positions of the lateral expansion body 2 are opened on the side wall of the hollow steel reinforced pipe column 1. The internal pouring of the hollow steel reinforced pipe column 1 There is a concrete body 3, and an anti-seepage body 4 is poured on the outer part of the hollow reinforced pipe column 1. A plurality of lateral expansion bodies 2 are embedded in the anti-seepage body 4, and a plurality of pouring holes 101 are distributed around the pouring pipe 201 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com