Fluoride-free waterproof finishing agent and preparation method thereof

A fluorine-free water-repellent and finishing agent technology, used in fiber treatment, fiber types, textiles and papermaking, etc., can solve problems such as poor application prospects, achieve stable water-repellent effect, high washing resistance, and no deterioration in hand feel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a preparation method of a fluorine-free waterproof finishing agent, comprising the following steps:

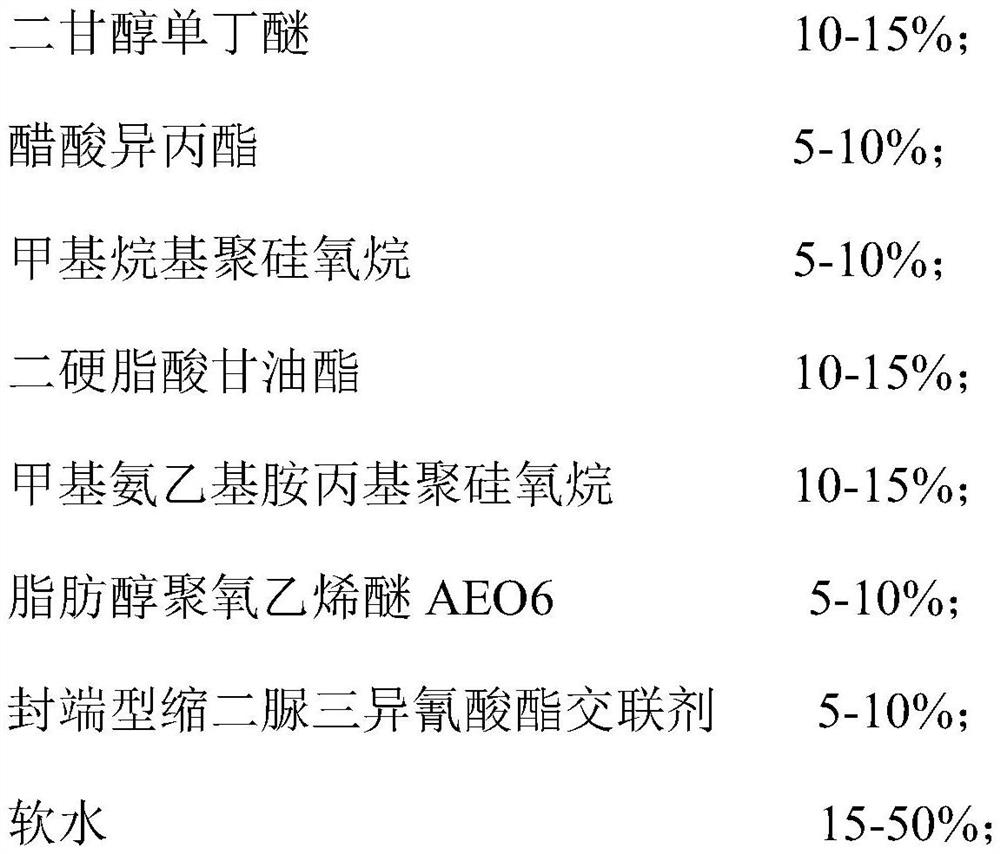

[0029] S1), fluorine-free waterproof finishing agent formula:

[0030]

[0031]

[0032] S2) preparation process:

[0033] Into a 1000ml stainless steel reaction kettle with a high-speed shearing device, 100g of diethylene glycol monobutyl ether, 50g of isopropyl acetate, 50g of methyl alkyl polysiloxane, and 100g of glyceryl distearate were injected successively. Mix well with 100g of methylaminoethylaminopropyl polysiloxane, stir for 20 minutes, inject 50g of fatty alcohol polyoxyethylene ether AEO6, stir for 15 minutes, turn on the high-shear emulsification equipment, slowly inject 500g of soft water, and emulsify After 1 hour, the system turned into a milky white liquid. Stop the emulsification device, turn on the ordinary stirring device, slowly add 50 g of blocked biuret triisocyanate crosslinking agent, and stir for 20 minutes to o...

Embodiment 2

[0035] This embodiment provides a preparation method of a fluorine-free waterproof finishing agent, comprising the following steps:

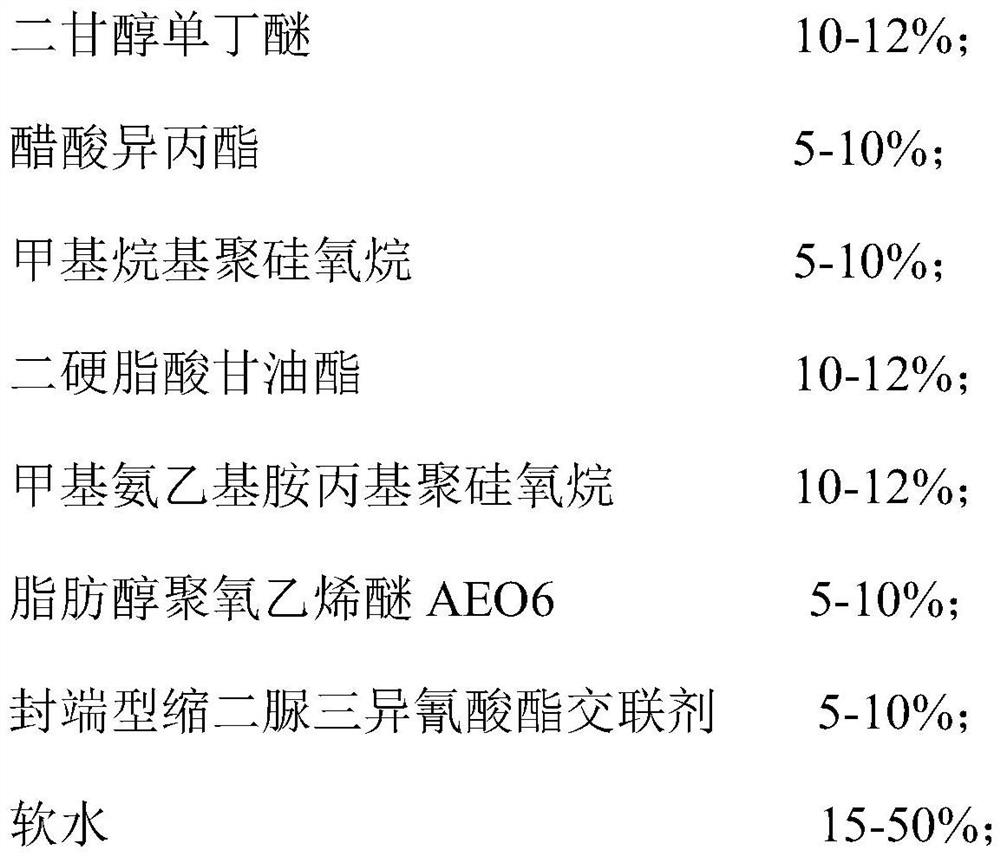

[0036] S1), fluorine-free waterproof finishing agent formula:

[0037]

[0038] S2), preparation process:

[0039] 125g of diethylene glycol monobutyl ether, 75g of isopropyl acetate, 75g of methyl alkylpolysiloxane, 125g of glyceryl distearate and methyl Mix 125g of aminoethylaminopropylpolysiloxane thoroughly, stir for 20 minutes, inject 75g of fatty alcohol polyoxyethylene ether AEO6, stir for 15 minutes, turn on the high-shear emulsification equipment, slowly inject 325g of soft water, and emulsify for 1 hour, the system Turn into a milky white liquid, stop the emulsification device, turn on the ordinary stirring device, slowly add 75g of blocked biuret triisocyanate crosslinking agent, and stir for 20 minutes to obtain the fluorine waterproof finishing agent.

Embodiment 3

[0041] Embodiment provides a kind of preparation method of fluorine-free waterproof finishing agent, comprises the following steps:

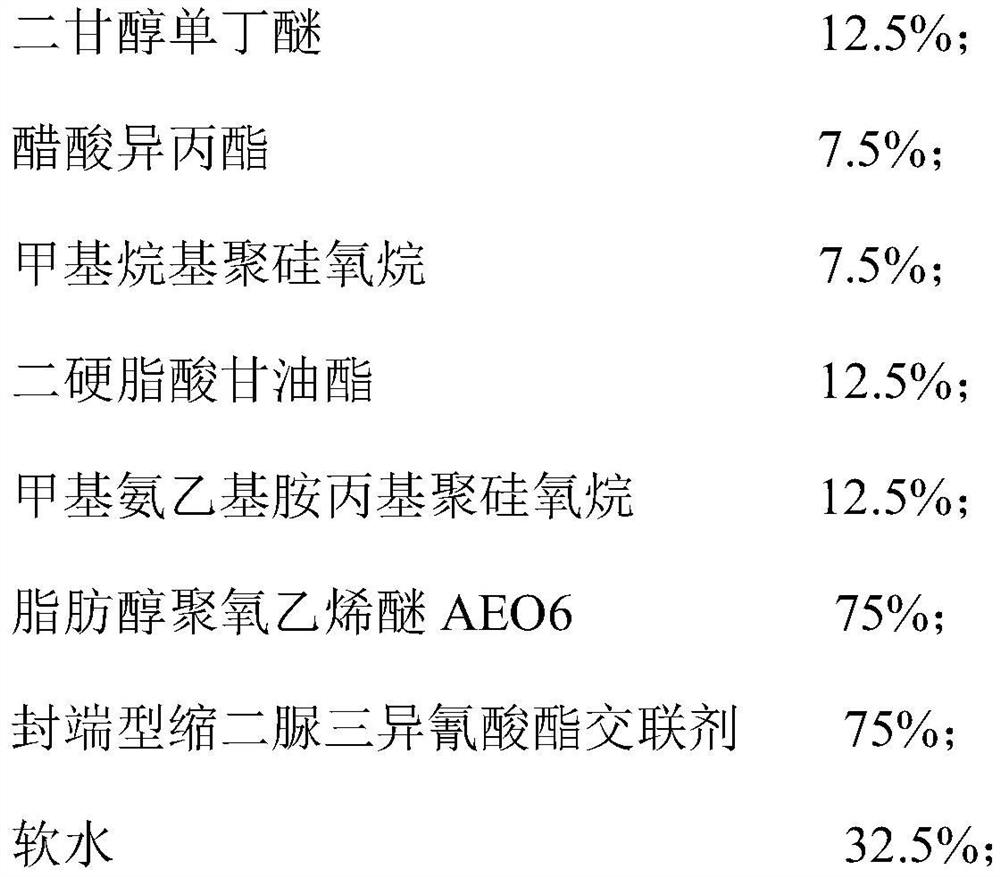

[0042] S1), fluorine-free waterproof finishing agent formula:

[0043]

[0044] S2), preparation process

[0045] 150g of diethylene glycol monobutyl ether, 100g of isopropyl acetate, 100g of methyl alkylpolysiloxane, 150g of glyceryl distearate and methyl Mix 20g of aminoethylaminopropyl polysiloxane thoroughly, stir for 20 minutes, inject 100g of fatty alcohol polyoxyethylene ether AEO6, stir for 15 minutes, turn on the high-shear emulsification equipment, slowly inject 150°C soft water, and emulsify for 1 hour, the system Turn into a milky white liquid, stop the emulsifying device, turn on the ordinary stirring device, slowly add 100 g of blocked biuret triisocyanate crosslinking agent, stir for 20 minutes, and obtain the fluorine waterproof finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com