Combustion chamber burner structure with heating system and operation method

A heating system and combustion chamber technology, which is applied in the coking field, can solve the problems of low temperature, large heat dissipation in the vertical fire channel of the burner, decrease in the strength of coke at the burner, etc., and achieves the effects of easy operation, saving resources and reducing the cost of coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure and operation method of a combustion chamber burner with a heating system according to the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited to the following embodiments, which are listed for illustrative purposes only and do not limit the present invention in any way.

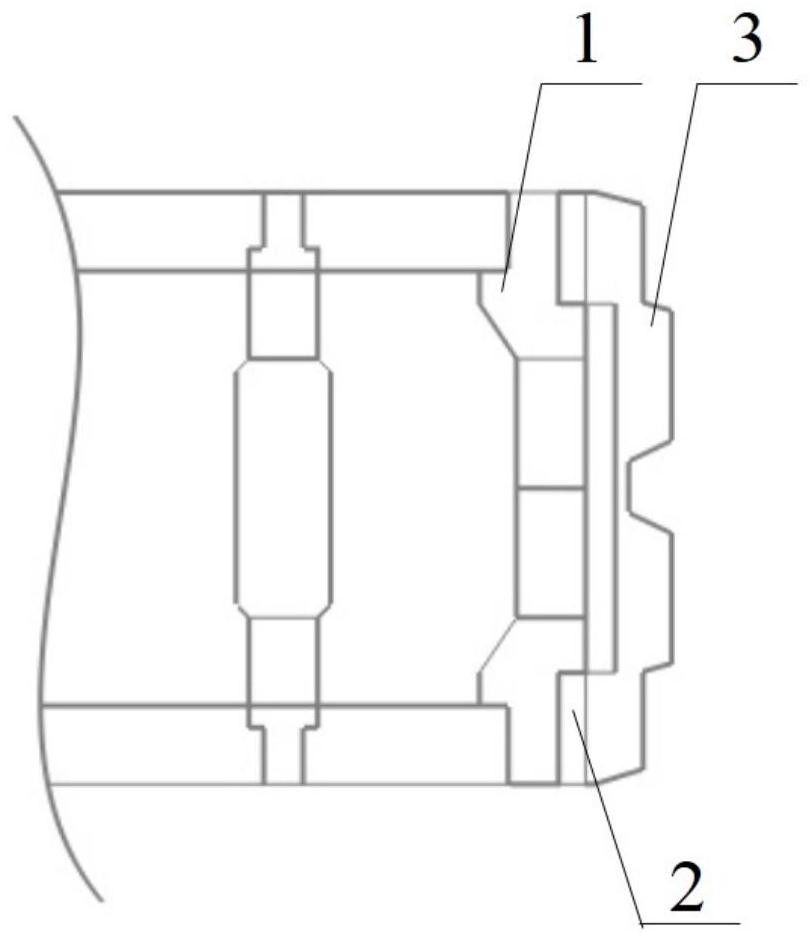

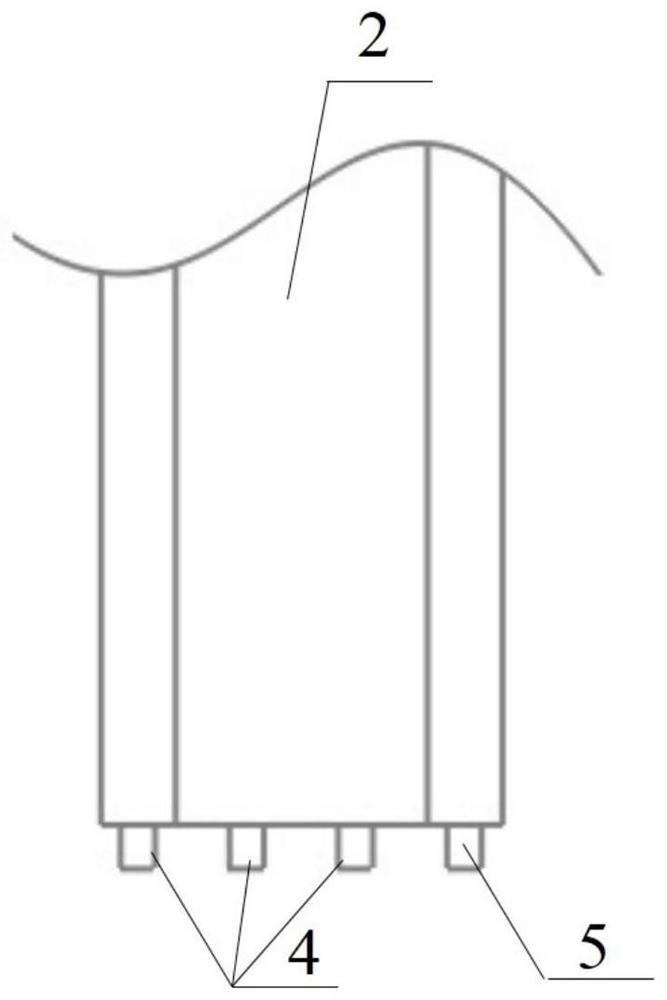

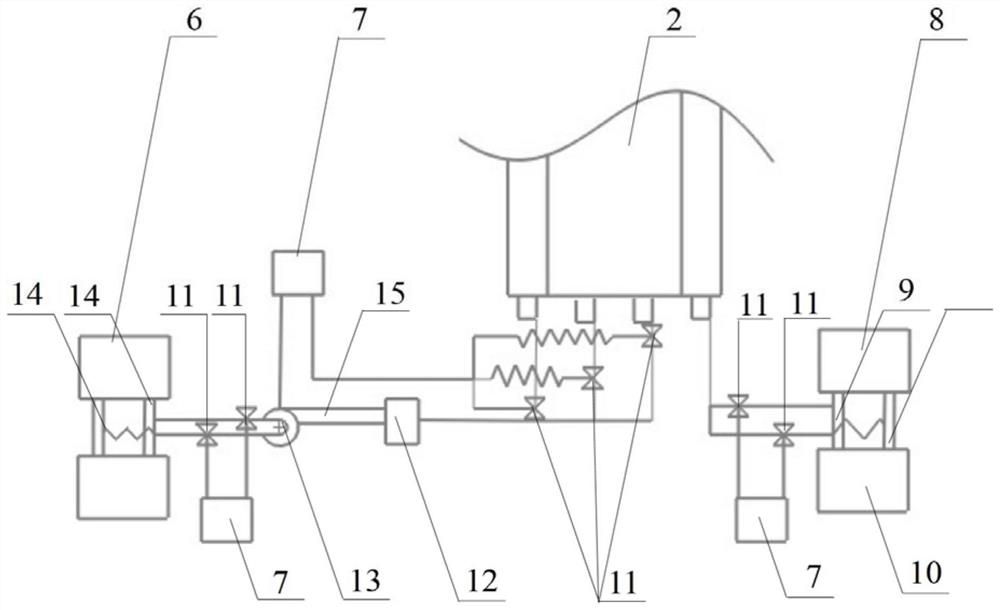

[0027] A combustion chamber furnace head structure with a heating system is characterized in that: a heating system is installed on the machine side and / or the coke side of the coke oven combustion chamber, the heating system includes a metal hollow plate 2, and the metal hollow plate 2 is set Between the inner refractory brick 1 and the outer refractory brick 3 of the furnace head masonry, the metal hollow plate 2 is connected to the inner refractory brick 1 and the inner side of the outer refractory brick 3 is the same, and the metal hollow plate 2 and the inner refractory brick 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com