Polyamide nanofiltration membrane with pattern surface and preparation method

A polyamide and nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of increasing the complexity of the membrane-making process, the complex chemical synthesis process, and the large amount of chemicals. The effect of improving water flux and salt selectivity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention has the preparation method of the polyamide nanofiltration membrane of pattern surface, it comprises the following steps:

[0036] The first step is to prepare aqueous phase and organic phase solutions: prepare an aqueous phase solution containing polyamines, the solvent of the aqueous phase solution is deionized water, and the concentration of monomers in the aqueous phase is 0.2 to 3.0% (w / v); prepare at least An acid chloride organic phase solution containing two reactive acid chloride groups, the organic phase monomer concentration is 0.01 to 2.0% (w / v);

[0037]The second step, interfacial polycondensation reaction: wash the supporting base film with deionized water and dry the surface moisture of the base film moderately, then immerse it in the aqueous phase solution prepared in the first step, dip coating at room temperature for 10s to 10min, remove the base film after taking it out The water phase solution remains on the surface; then immer...

Embodiment 1

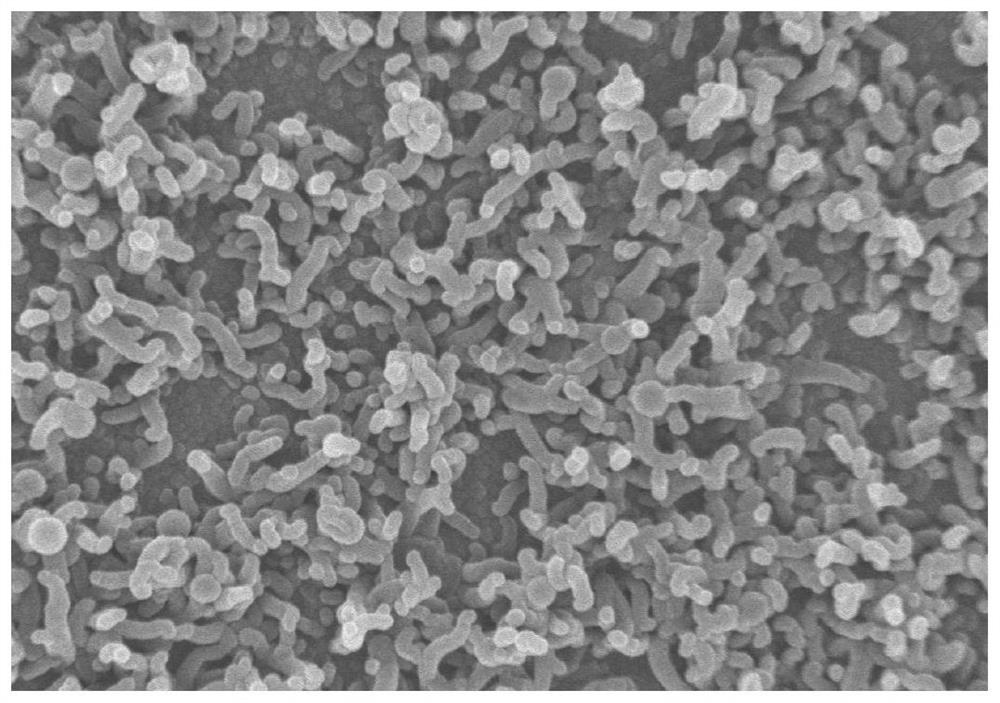

[0047] Soak the polyvinyl chloride hollow fiber ultrafiltration membrane as the base membrane in the piperazine aqueous phase solution with a concentration of 0.2% (w / v) for 30s, then remove the excess aqueous phase solution with absorbent filter paper and dry it in the air for 300s, then The base film was immersed in a 0.1% (w / v) n-decane-trimesoyl chloride organic solution to react for 10 seconds, and the temperature of the organic phase solution was 0°C. After the reaction, the first polyamide nanofiltration membrane with a tubular topography pattern surface was obtained, such as figure 1 shown. The polyamide nanofiltration membrane with the surface of the tubular topography pattern was left to stand in the air for 15 minutes, and then washed with deionized water to be tested. The polyamide nanofiltration membrane with a tubular topography pattern surface obtained under this condition has a negative effect on Na 2 SO 4 The rejection rate is 92.6%, the rejection rate of N...

Embodiment 2

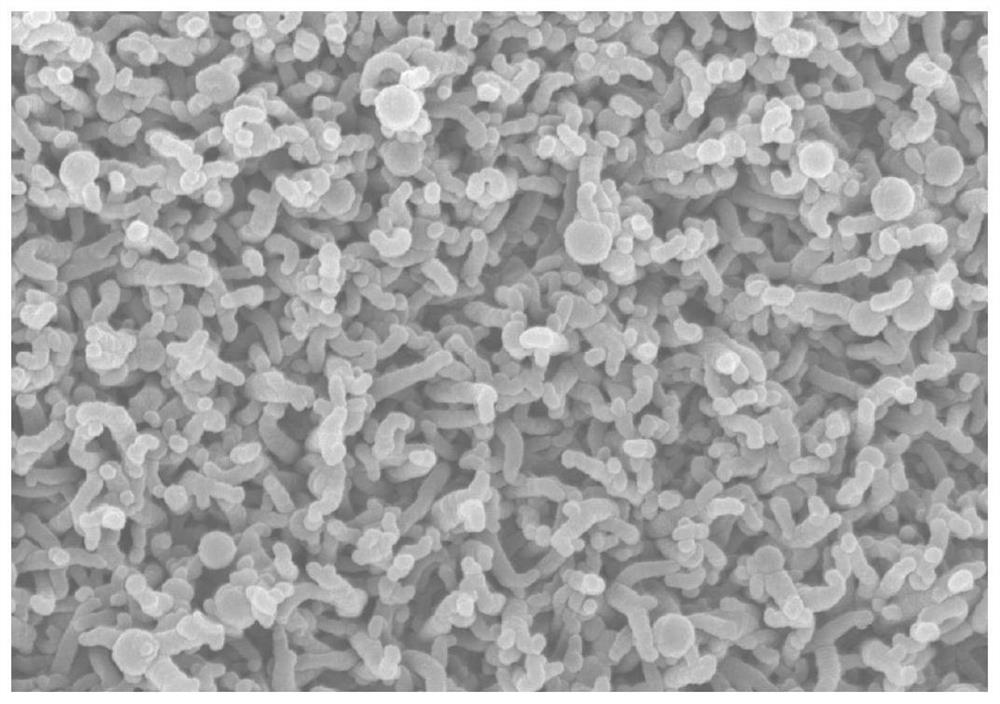

[0049] Soak the polyvinyl chloride hollow fiber base membrane in the piperazine aqueous phase solution with a concentration of 0.8% (w / v) for 5 minutes, then remove the excess aqueous phase solution with absorbent filter paper, dry it in the air for 30 seconds, and then immerse the base membrane in Reaction in the n-heptane-trimesoyl chloride organic solution with a concentration of 0.1% (w / v) for 2 minutes, the temperature of the organic phase solution is 0°C, and the second polyamide nanofiltration with a tubular topography pattern surface is obtained after the reaction film, such as figure 2 shown. The polyamide nanofiltration membrane with the surface of the tubular topography pattern was taken out, placed in the air for 15 minutes, and then washed with deionized water to be tested. The polyamide nanofiltration membrane with a tubular topography pattern surface obtained under this condition has a negative effect on Na 2 SO 4 The rejection rate is 95.2%, the rejection r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water flux | aaaaa | aaaaa |

| Inner and outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com