A self-heating type power adapter

A technology of power adapter and self-heating, which is applied in the direction of electrical components, chemical instruments and methods, and power electronics modification, can solve the problems of increasing the size of the power adapter, reducing the dust resistance of the power adapter, and reducing the portability of the power adapter, etc., to achieve Improve heat absorption, improve dustproof ability, increase the effect of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

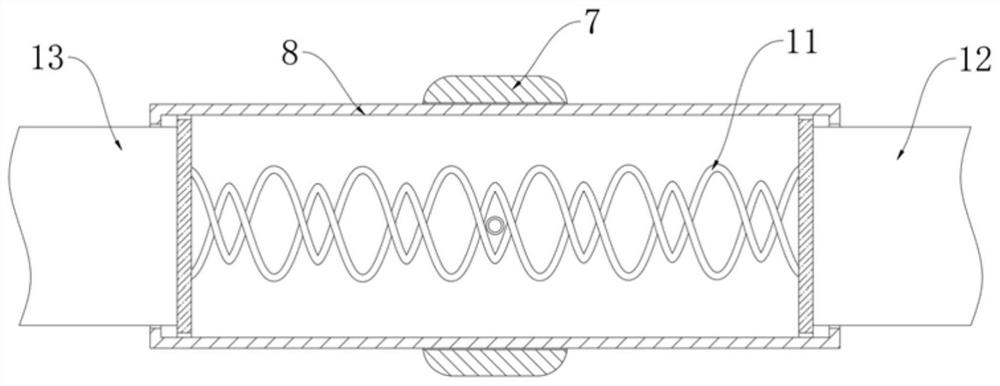

[0027] refer to Figure 1-5 , a self-radiating power adapter, including a housing 1, a heat dissipation hole 10 is opened through the side wall of the housing 1, a straight cylinder 8 is fitted in the heat dissipation hole 10 through a fixing part 7, and a thermal deformation is provided in the straight cylinder 8. 11, and the middle part of the heat-deformable part 11 is elastically connected with the inner wall of the straight cylinder 8. The heat-deformable part 11 is made of a memory alloy. When the temperature reaches the transformation temperature of the memory alloy, the heat-deformable part 11 will change from a contracted state to a stretched state , both ends of the thermally deformable member 11 are respectively fixedly connected with a first heat conduction rod 12 and a second heat conduction rod 13, and both the first heat conduction rod 12 and the second heat conduction rod 13 are slidingly connected with the straight cylinder 8;

[0028] The outer side of the ho...

Embodiment 2

[0035] refer to Figure 6-7 The difference between this embodiment and Embodiment 1 is that two sealing grooves 14 are symmetrically opened in the side wall of the housing 1, and a sliding plug 15 is arranged for sealing and sliding in each sealing groove 14, and each sealing groove 14 is close to One end of the cooling hole 10 is communicated with the cooling hole 10 through the air duct 16;

[0036] One end of the air duct 16 close to the heat dissipation hole 10 is arc-shaped, and is inclined to the outside of the heat dissipation hole 10 .

[0037] In this embodiment, each sealing groove 14 is provided with an expansion medium, and the expansion medium is located on the side of the corresponding slide plug 15 away from the cooling hole 10, and each air duct 16 is provided with a pressure valve. Dust-proof nets are clamped in the air ducts 16 to improve the dust-proof capability of the air ducts 16 .

[0038] When used in this embodiment, the expansion medium can be a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com