Composite cathode material and preparation method and application thereof, and lithium ion battery

A composite cathode material, lithium-ion battery technology, applied in the direction of positive electrode, battery electrode, secondary battery, etc., can solve the problems of poor battery cycle performance and low lithium replenishment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

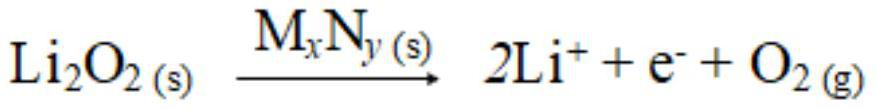

AI Technical Summary

Problems solved by technology

Method used

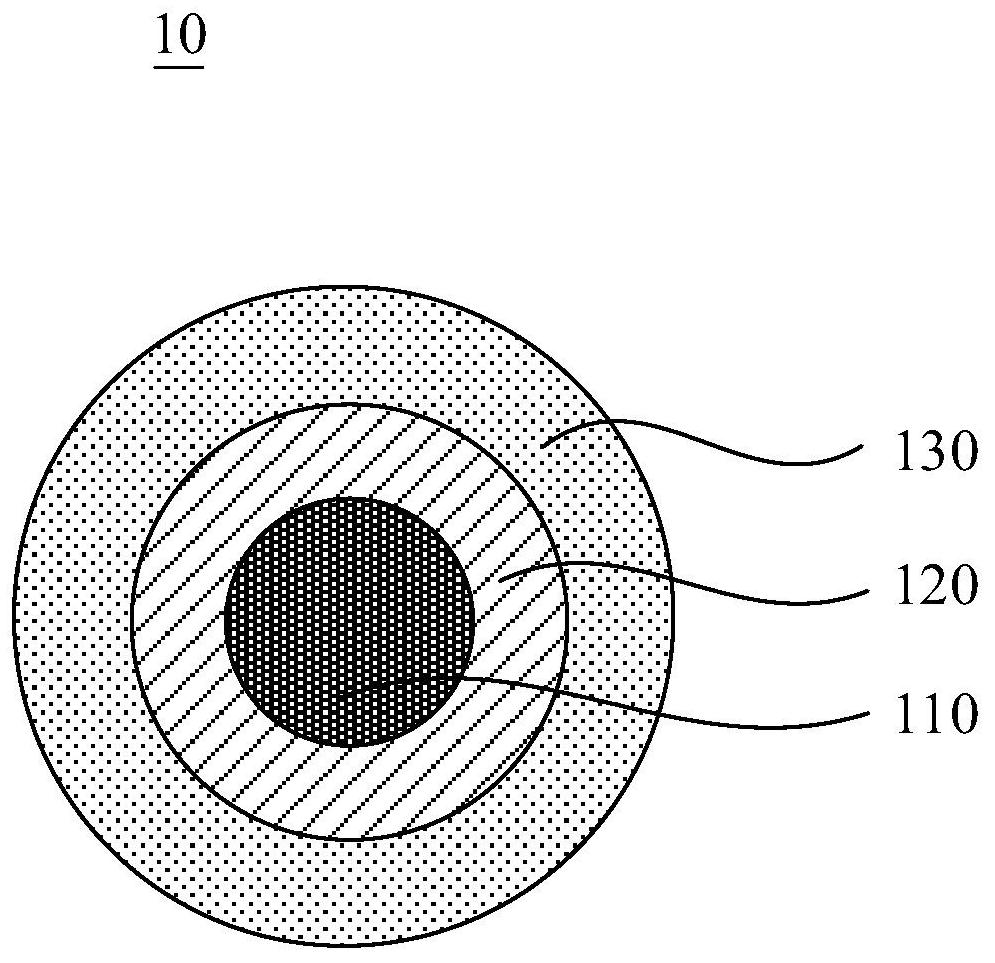

Image

Examples

preparation example Construction

[0035] A preparation method of a composite positive electrode material is one of the preparation methods of the above composite positive electrode material, and the preparation method of the composite positive electrode material comprises the following steps:

[0036] Step S210: ball milling and mixing the positive electrode material and the metal compound to obtain a coating.

[0037] Wherein, after ball milling, the surface of the positive electrode material is coated with a layer of metal compound to form a metal compound layer, that is, the coating is the positive electrode material whose surface is coated with the metal compound.

[0038] Further, in the step of ball milling and mixing the positive electrode material and the metal compound, the rotational speed of the ball mill is 200 rpm to 600 rpm, and the time of ball milling is 30 min to 50 min. Specifically, a ball mill is used for ball milling. More specifically, the mass ratio of the ball milling beads to the posi...

Embodiment 1

[0053] The preparation steps of the composite cathode material of this embodiment are as follows:

[0054] LiCoO 2 Cathode material and NiF 2 At the same time, it was added to a ball mill and ball milled for 30 minutes at a speed of 200 rpm to obtain NiF 2 Coated LiCoO 2 Cathode material, among them, NiF 2 accounted for LiCoO 2 With a mass fraction of 0.2wt%, the ball-milled beads with LiCoO 2 The mass ratio is 10:1.

[0055] Then, the NiF 2 Coated LiCoO 2 Cathode material added Li 2 o 2 In methanol solution, stirred at a temperature of 80°C and a stirring speed of 400rpm until the solvent was completely evaporated, and the solid was dried at 120°C for 12h to obtain Li 2 o 2 and NiF 2 Double-coated composite cathode materials, in which Li 2 o 2 accounted for LiCoO 2 The mass fraction of is 1wt%.

Embodiment 2

[0057] The preparation steps of the composite cathode material of this embodiment are as follows:

[0058] LiMn 2 o 4 Cathode material and CoF 2 At the same time, it was added to a ball mill and ball milled for 40 minutes at a speed of 400rpm to obtain CoF 2 Coated LiMn 2 o 4 Cathode materials, among which, CoF 2 accounted for LiMn 2 o 4 The mass fraction is 0.1wt%, and the ball-milled beads with LiMn 2 o 4 The mass ratio is 15:1.

[0059] Then, the CoF 2 Coated LiMn 2 o 4 The material is added to Li 2 o 2 In the isopropanol solution, stir at a temperature of 60°C and a stirring speed of 500rpm until the solvent is completely evaporated. After the solid is dried at 120°C for 12h, the obtained Li 2 o 2 and CoF 2 Double-coated composite cathode materials, in which Li 2 o 2 accounted for LiMn 2 o 4 The mass fraction of is 2wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com