Variable-angle synchronous phase shift interference measurement method for gear tooth surface shape errors

A technology of interferometric measurement and synchronous phase shift, which is applied in the field of optical measurement, can solve the problems of low precision and inability to realize full-field measurement, achieve the effects of large measurement range, increased anti-interference ability, and simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

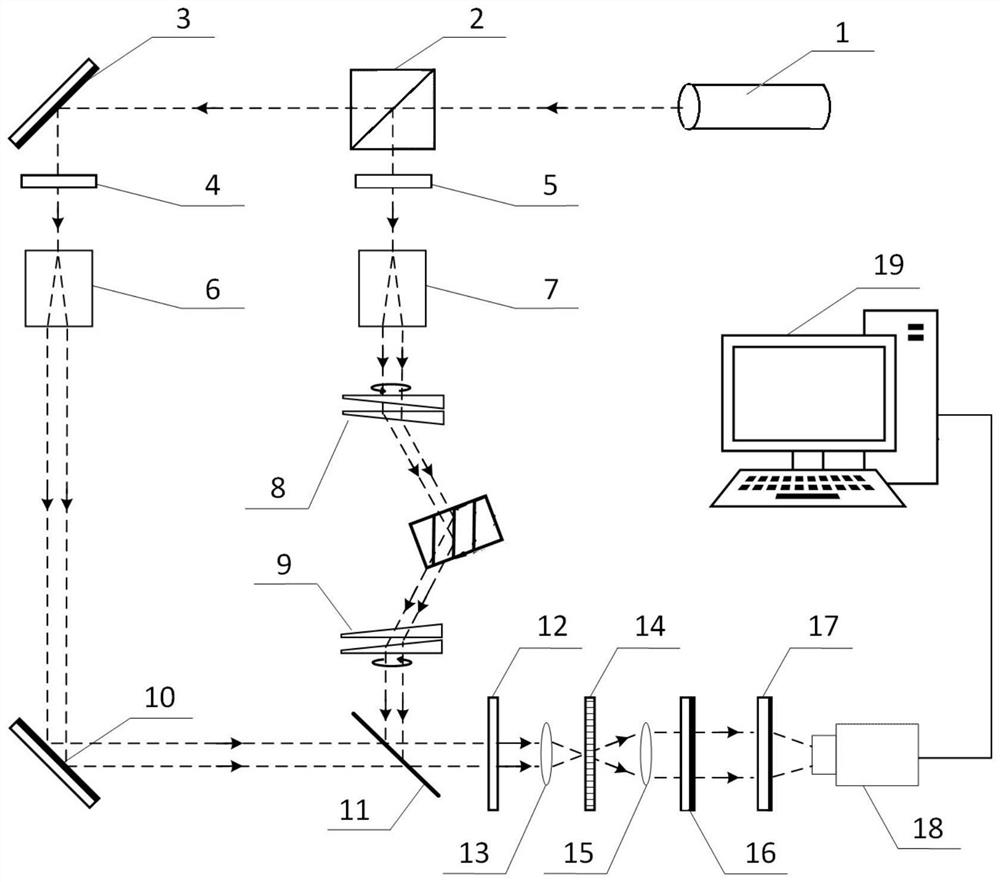

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0066] A variable-angle synchronous phase-shift interferometry method for gear tooth surface shape errors, specifically implemented according to the following steps:

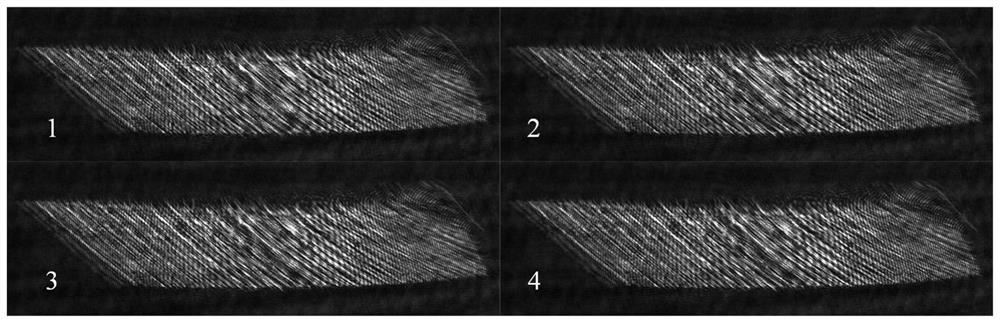

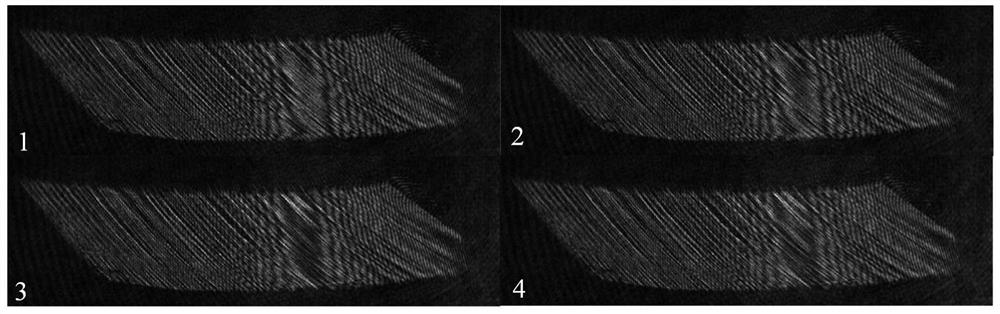

[0067] Step 1. Place the gear to be tested between the front double optical wedge 8 and the rear double optical wedge 9 in the interferometric optical path, and adjust the interferometric optical path. When the interferometric optical path is adjusted properly, the CCD camera 18 will capture the gear to be tested. Surface interference fringe image;

[0068] Step 2. By rotating the front double optical wedge 8 and the rear and front double optical wedge 9, the relative angle between the double optical wedges is changed, and the incident angle of the interferometric optical path irradiating the measured tooth surface of the measured gear is changed. In the case of measuring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com