Tunnel feet-lock anchor rod accurate positioning and construction method

A technology of locking foot bolts and precise positioning, which can be used in the installation of bolts, earthwork drilling, mining equipment, etc. It can solve problems such as tunnel convergence or settlement deformation, affecting the stability of steel frames, and poor connection quality of steel frames, etc., to achieve Good social benefits, improving construction efficiency, and facilitating the installation of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

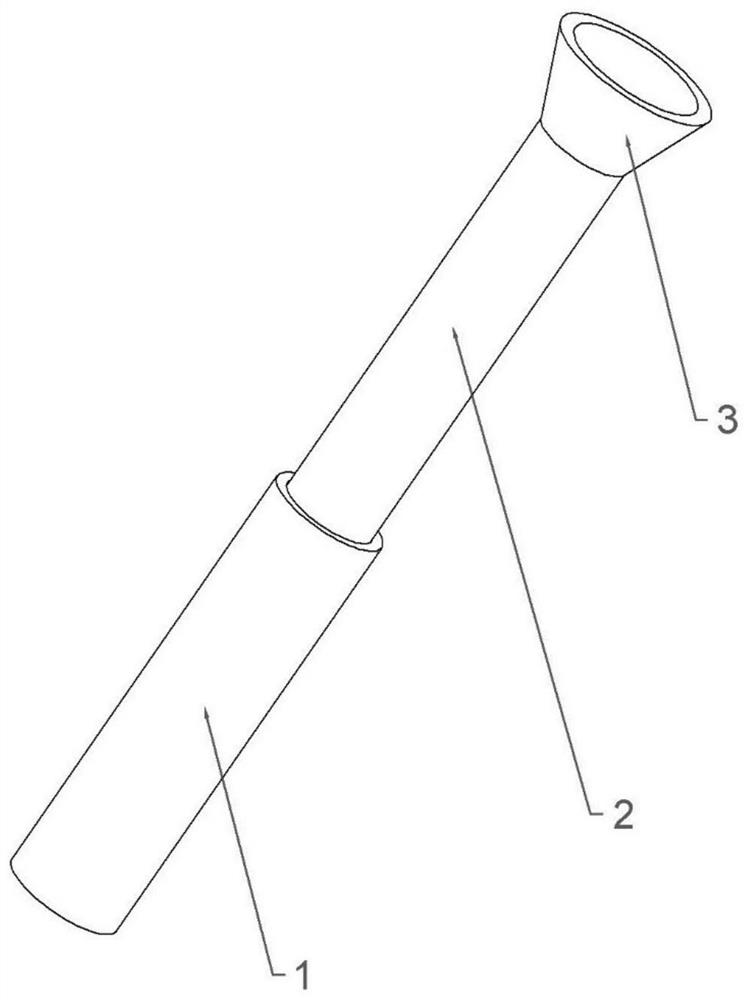

[0046] Such as image 3 , Figure 4 and Figure 5 As shown, the difference between the present embodiment and the first embodiment is that the guide tube 8 in the locking foot anchor tube positioning device in the present embodiment includes an inner tube 2 and an outer tube 1, and the inner tube 2 is located in the outer tube 1 and is in contact with the outer tube 1. The tube 1 is slidably fitted. Specifically, the inner wall of the outer tube 1 is provided with a chute along the axial direction, and the outer side of the inner tube 2 is provided with a convex line along the axial direction. The inner tube 2 is provided with a scale. The end of the inner tube 2 away from the outer tube 1 is provided with a fixed shell 3, which is in the shape of a truncated cone. The inner tube 2 is provided with a positioning ring 5, which is connected to the inner wall of the inner tube 2 through the connecting rod 4, and the number of the positioning rings 5 is multiple and distribut...

Embodiment 3

[0049] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the diameter of the positioning ring 5 in this embodiment can be adjusted. Specifically, a plurality of through holes are evenly opened in the circumferential direction of the inner tube 2, and the number of through holes in this embodiment is the same as the number of the connecting rods 4, which are three. The positioning ring 5 is composed of three positioning sub-rings 15 having the same shape, and the three positioning sub-rings 15 can form a circular positioning ring 5 . The three connecting rods 4 pass through the through holes respectively, and the ends of the connecting rods 4 located in the inner tube 2 are connected to the positioning sub-ring 15, and the connection method can be threaded connection, card connection or other connection methods. The outer end of the inner tube 2 is provided with a rotating tube 11, and the rotating tube 11 is slidingly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com