Composite drainage gas production string and its method for discharging fluid in "lying well"

A gas production pipe and liquid accumulation technology, which is applied to the components of pumping devices for elastic fluids, wellbore/well components, drilling pipes, etc., can solve the problems of high construction cost, difficulty in electric power, and high input-output ratio. Achieve the effect of increasing corrosion resistance and impact resistance, efficient drainage technology, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

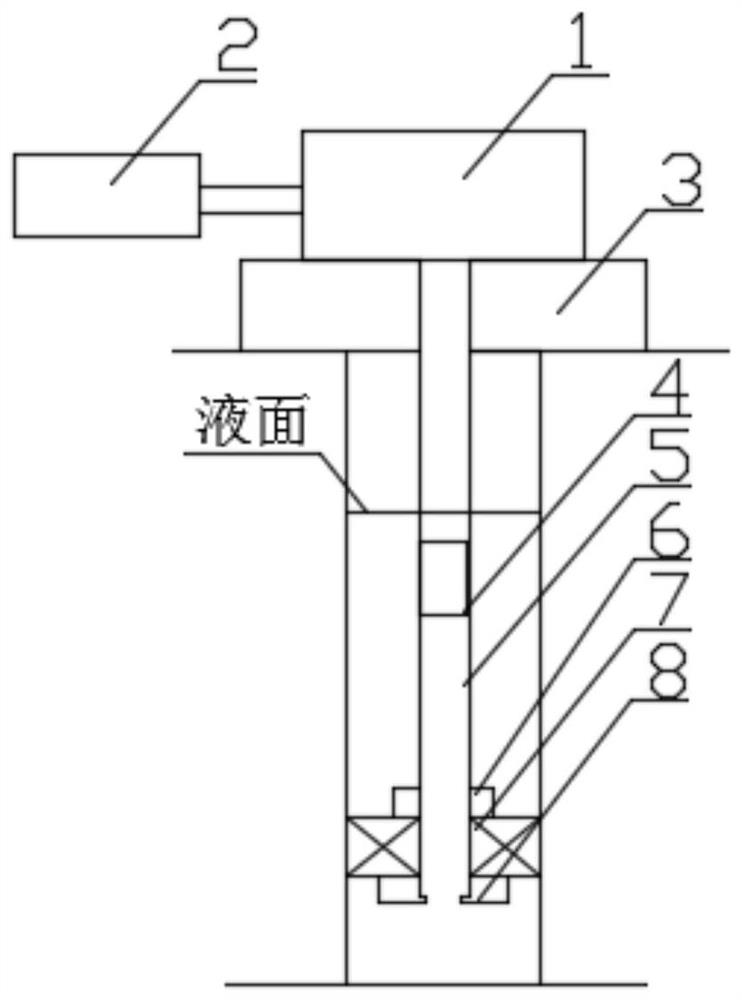

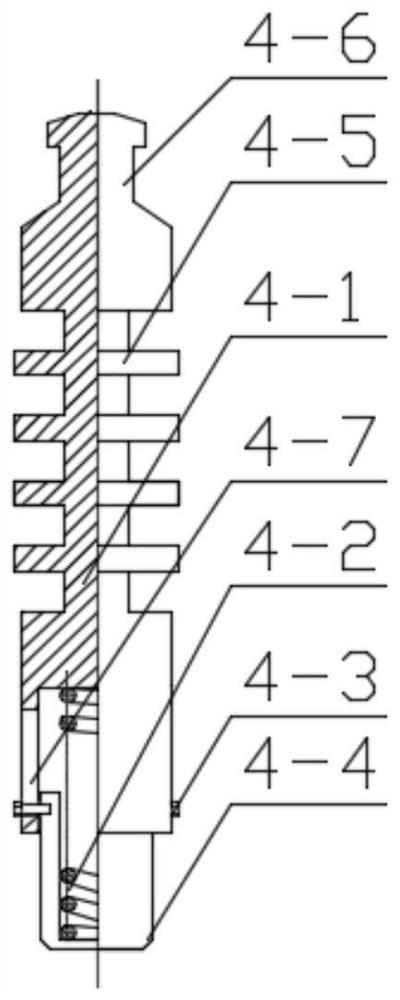

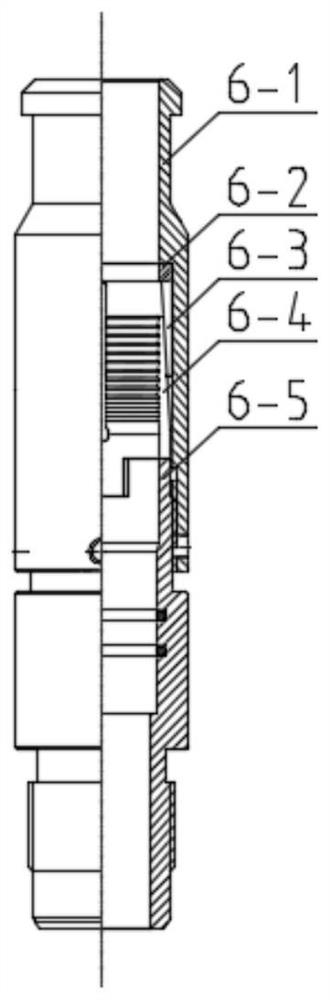

[0034] like figure 1 As shown in the figure, the composite drainage gas production pipe string used for "lying well" downhole liquid discharge includes a plunger blowout preventer 1, a plunger ground control system 2, a Christmas tree 3, a plunger 4, a velocity string 5, a pipe Column joint 6, packer 7 and ball seat 8; wherein, plunger blowout preventer 1, Christmas tree 3, velocity string 5, pipe string joint 6, packer 7 and ball seat 8 are in order from top to bottom connection; the plunger ground control system 2 is connected with the plunger blowout preventer 1; the plunger 4 is arranged in the velocity pipe string 5, so that it can move up and down in the velocity pipe string 5;

[0035] The plunger blowout preventer 1, the plunger ground control system 2 and the Christmas tree 3 are all commercially available products; among them, the plunger blowout preventer 1 has the functions of plunger throwing, taking out and capturing, and is connected to the Christmas tree throug...

Embodiment 2

[0049] The bottom-hole drainage gas production construction realized by the composite drainage gas production pipe string used for "lying well" downhole liquid discharge in Example 1, its specific implementation steps are as follows:

[0050] S1. Connect the velocity string 5, the string joint 6, the packer 7 and the ball seat 8 in sequence from top to bottom to form a downhole composite gas production string;

[0051] S2. According to the depth of the liquid level in the downhole, according to the measurement results of the depth of the liquid level, the structure of the wellbore and the position of the reservoir, design the running position of the downhole composite gas production string;

[0052] S3, run the gas production pipe string into the wellbore design position by using the speed pipe string 5 running supporting equipment, and cut off the redundant speed pipe string 5, and connect it with the gas tree 3 through the wellhead device;

[0053] S4. Put soluble balls 9 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com