Separation device for centimillimeter particles in flue gas

A particle separation and flue gas technology, which is applied in the manufacture of converters, etc., can solve the problems of easy fouling on the inner wall of the evaporative cooler, no waste, waste of high-temperature energy of the flue gas, etc., to achieve secondary utilization, low energy consumption, The effect of shortening the falling distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

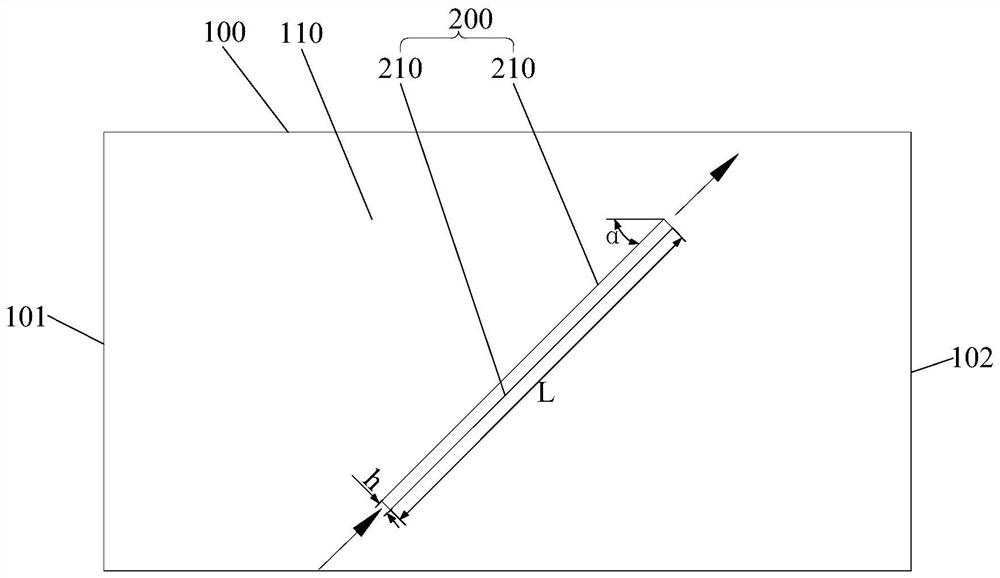

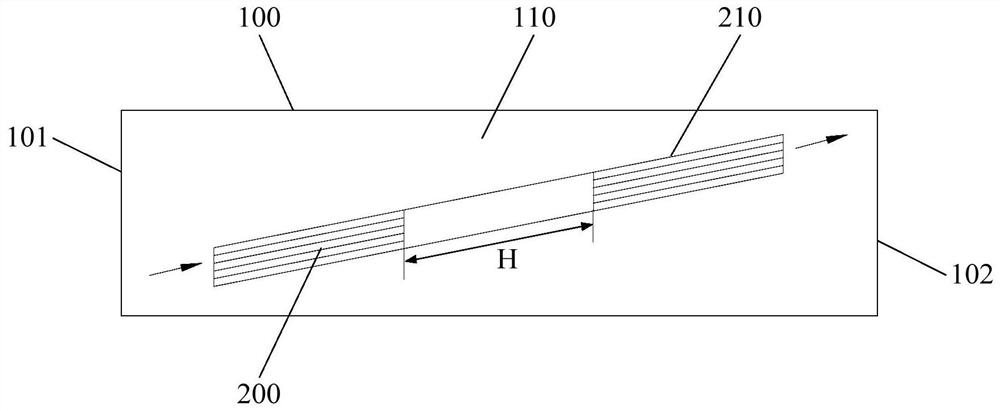

[0034] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the use of adjective or adverbial modifiers "inside" and "outside" is only for the convenience of relative reference between groups of terms, and does not describe any specific directional limitation on the modified terms. In the description of the present invention, unless otherwise specified, "plurality" means two or more. exist figure 1 and figure 2 In the figure, the solid line short arrow is the flue gas flow direction, and the meaning of "high temperature" is 650°C to 800°C.

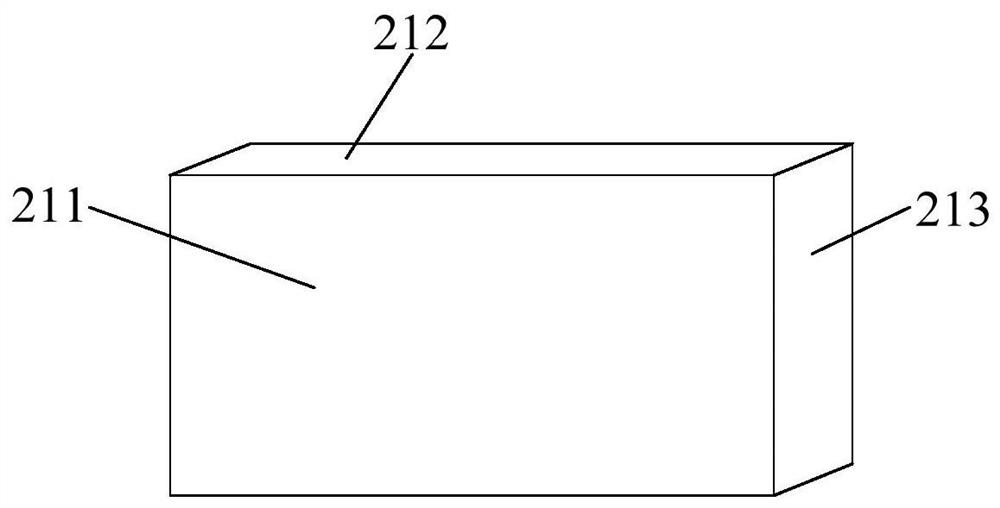

[0035] like figure 1 and figure 2 As shown, the present invention provides a flue gas 10m-level particle separation device, which is arranged in the settling area 110 of the flue gas, and the flue gas 100m-level particle separation dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com