A kind of method that utilizes wet film coating method to prepare silk protein thin film

A technology of silk protein and regenerated silk fibroin, which is applied in the field of preparation of silk protein films, can solve the problems of large film thickness, difficulty in effective control, and unsatisfactory mechanical properties, and achieve good mechanical properties, excellent mechanical properties, and excellent self-supporting sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare a lithium chloride-formic acid solution with a concentration of 0.5wt%, take 0.4g of degummed silk and dissolve it in 7.8ml of the above solution, place it in an ultrasonic cleaner for oscillation for 1 hour, and filter the solution with a PTFE filter membrane with a pore size of 0.45 μm to obtain regeneration Silk fibroin solution.

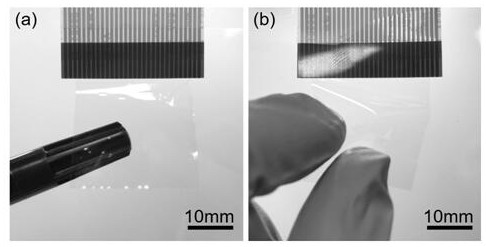

[0038] Use a clean PET substrate with a water drop angle of 79.1°, set the scraper thickness of the scraper to 0.1 μm, and apply a layer of regenerated silk fibroin wet film by scraping; place the film on a hot stage at 60°C to dry for 5 minutes; The film was soaked in water for 0.5min, and then dried on a hot table at 60°C; by mechanical peeling, the dried regenerated silk fibroin film was peeled off from the substrate to obtain a self-supporting flexible silk protein film, which was finally formed into a film The thickness is about 0.05μm and the flatness is good.

Embodiment 2

[0040]Prepare a lithium bromide-formic acid solution with a concentration of 8.7wt%, take 2.5g of degummed silk and dissolve it in 5.7ml of the above solution, place it in an ultrasonic cleaner for oscillation for 1 hour, and filter the solution with a PTFE filter membrane with a pore size of 0.45 μm to obtain regenerated silk fibroin protein solution.

[0041] Using a clean polyimide PI substrate with a water drop angle of 82°, using a four-sided preparation device with a thickness of 200 μm, scrape and coat a layer of silk protein wet film; place the film on a hot table at 60°C to dry for 10 minutes; The film was soaked in water for 20 minutes, and then dried on a hot table at 60°C; by mechanical peeling, the dried silk protein film was peeled off from the substrate to obtain a self-supporting flexible silk protein film, and the final film thickness was about 25μm and good flatness.

Embodiment 3

[0043] Calcium chloride-formic acid solution with a concentration of 4.8wt% is prepared, 1.3g of degummed silk is dissolved in 6.8ml of the above solution, placed in an ultrasonic cleaner to vibrate for 1 hour, and the solution is filtered with a PTFE filter membrane with a pore size of 0.45 μm to obtain regeneration Silk fibroin solution.

[0044] Using a clean PET substrate with a water drop angle of 85°, use a four-sided preparation device with a thickness of 100 μm to scrape and coat a silk protein wet film; place the film on a hot table at 60°C for 10 minutes; rinse the dried film in water for 5 minutes, Then dry it on a hot table at 60°C; use mechanical peeling method to peel the dried silk protein film from the substrate to obtain an ultra-thin flexible silk protein film. The final film thickness is about 9 μm and the flatness is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com