Preparation method of microbial granules, microbial compound fertilizer and preparation method

A technology of microbial bacteria and microbial liquid, applied in the field of microbial compound fertilizers, can solve the problems of low microbial survival rate and achieve the effects of improving microbial survival rate, salt tolerance and survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

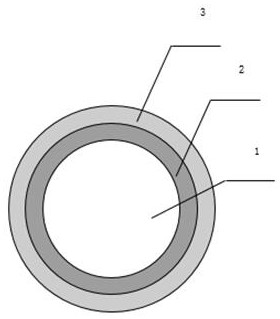

Image

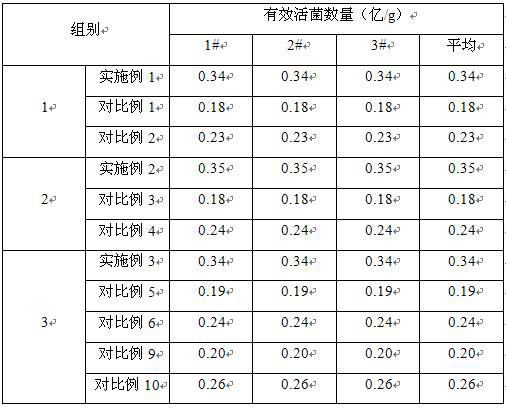

Examples

Embodiment 1

[0050] A preparation method for microbial bacterium grains for microbial compound fertilizers, comprising the steps of:

[0051] Step 1. Add beneficial microorganisms to the mixed nutrient solution, then add porous hydroxyapatite to the mixed nutrient solution, and perform aeration treatment (the moisture content of the solution during the aeration treatment process is 50%, and the temperature of the aeration treatment is 20°C, the time of aeration treatment is 5 days), and the porous hydroxyapatite loaded with microorganisms is obtained; wherein, the mixed nutrient solution includes trehalose, ectoine, and nutrients, and the beneficial microorganism liquid, trehalose , ectoine, nutrient, and the parts by weight of porous hydroxyapatite are 10, 2, 2, 3, 30 in sequence; the porosity of the porous hydroxyapatite is 60 to 75%, and the particle size is 100 to 300 μm, the pore size is 2~5 μm; the microbial content in the beneficial microorganism liquid is 6×10 11 spores / ml, the mi...

Embodiment 2

[0077] A preparation method for microbial bacterium grains for microbial compound fertilizers, comprising the steps of:

[0078] Step 1. Add the beneficial microorganism liquid into the mixed nutrient solution, then add porous hydroxyapatite to the mixed nutrient solution, and perform aeration treatment (the moisture content of the solution during the aeration treatment process is 60%, and the temperature of the aeration treatment is 30°C, the time of aeration treatment is 5 days), and the porous hydroxyapatite loaded with microorganisms can be obtained; wherein, the mixed nutrient solution includes trehalose, ectoine, nutrients, and the beneficial microorganism bacteria solution, trehalose , ectoine, nutrient, and the parts by weight of porous hydroxyapatite are 20, 4, 4, 6, and 40 in sequence; the porosity of the porous hydroxyapatite is 60 to 75%, and the particle size is 100 to 300 μm, the pore size is 2~5 μm; the microbial content in the beneficial microorganism liquid is...

Embodiment 3

[0090] A preparation method for microbial bacterium grains for microbial compound fertilizers, comprising the steps of:

[0091] Step 1. Add the beneficial microorganism liquid into the mixed nutrient solution, then add porous hydroxyapatite to the mixed nutrient solution, and perform aeration treatment (the moisture content of the solution during the aeration treatment process is 55%, and the temperature of the aeration treatment is 25°C, the time of aeration treatment is 5 days), and the porous hydroxyapatite loaded with microorganisms can be obtained; wherein, the mixed nutrient solution includes trehalose, ectoine, and nutrients, and the beneficial microorganism liquid, trehalose , ectoine, nutrient, and the parts by weight of porous hydroxyapatite are 14, 3, 3, 5, and 35 in sequence; the porosity of the porous hydroxyapatite is 60 to 75%, and the particle size is 100 to 300 μm, the pore size is 2~5 μm; the microbial content in the beneficial microorganism liquid is 6×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com