Sewage treatment device capable of controlling product crystallization granularity and sewage treatment method

A sewage treatment device and crystal particle size technology, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of inability to simultaneously realize efficient interception and granulation of crystals, and achieve maintenance The effect of small operation difficulty, low transformation cost and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

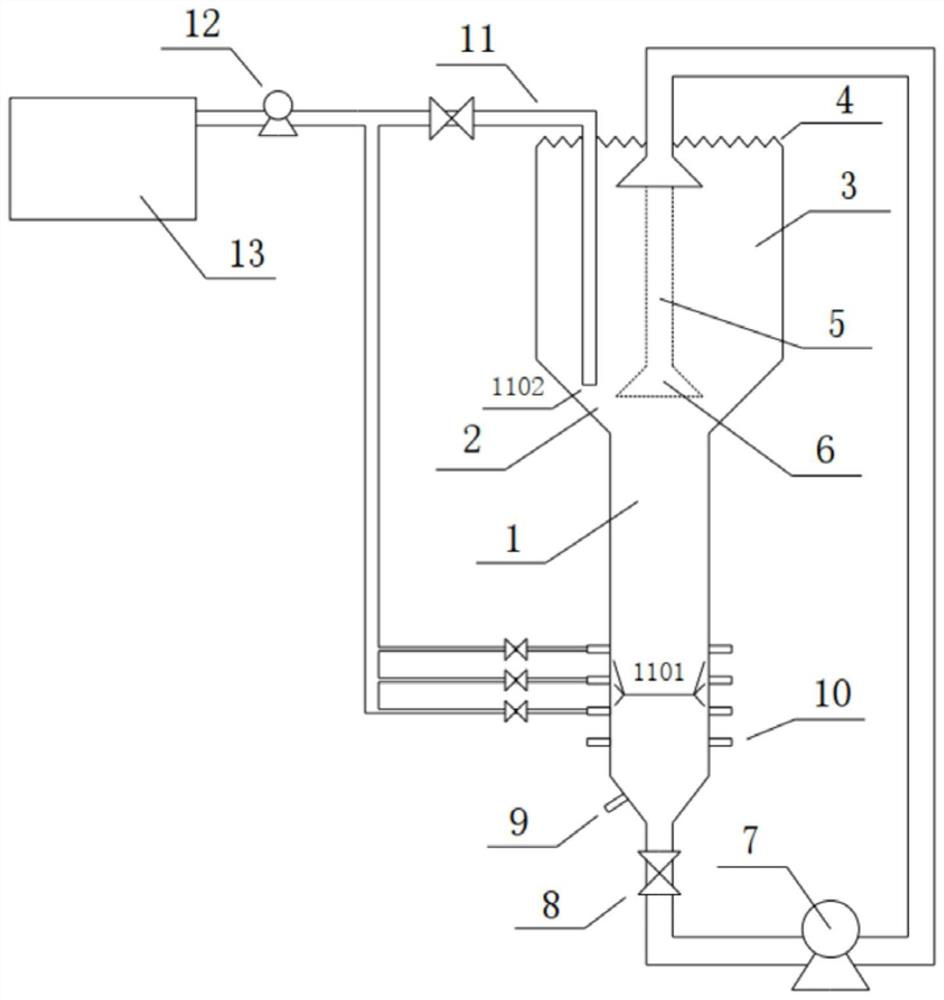

[0041] The present embodiment provides a sewage treatment device capable of controlling the crystallization size of the product, such as figure 1 As shown, the sewage treatment device includes a fluidized bed main body, a reflux device and a dosing device. The fluidized bed main body is sequentially provided with a sedimentation zone 3, a transition zone 2 and a fluidization zone 1 from top to bottom, and the reflux device passes through the reflux pipe 5 Connected with the main body of the fluidized bed, the reflux pipe 5 extends from the precipitation zone 3 into the main body of the fluidized bed, and can control the particle size of the crystallized product by changing the height of the reflux port 6 at the bottom end of the reflux pipe in the main body of the fluidized bed.

[0042] By improving the reflux device, the present invention makes full use of the crystal growth law and fluid flow characteristics in the main body of the fluidized bed, and creatively proposes a heig...

Embodiment 2

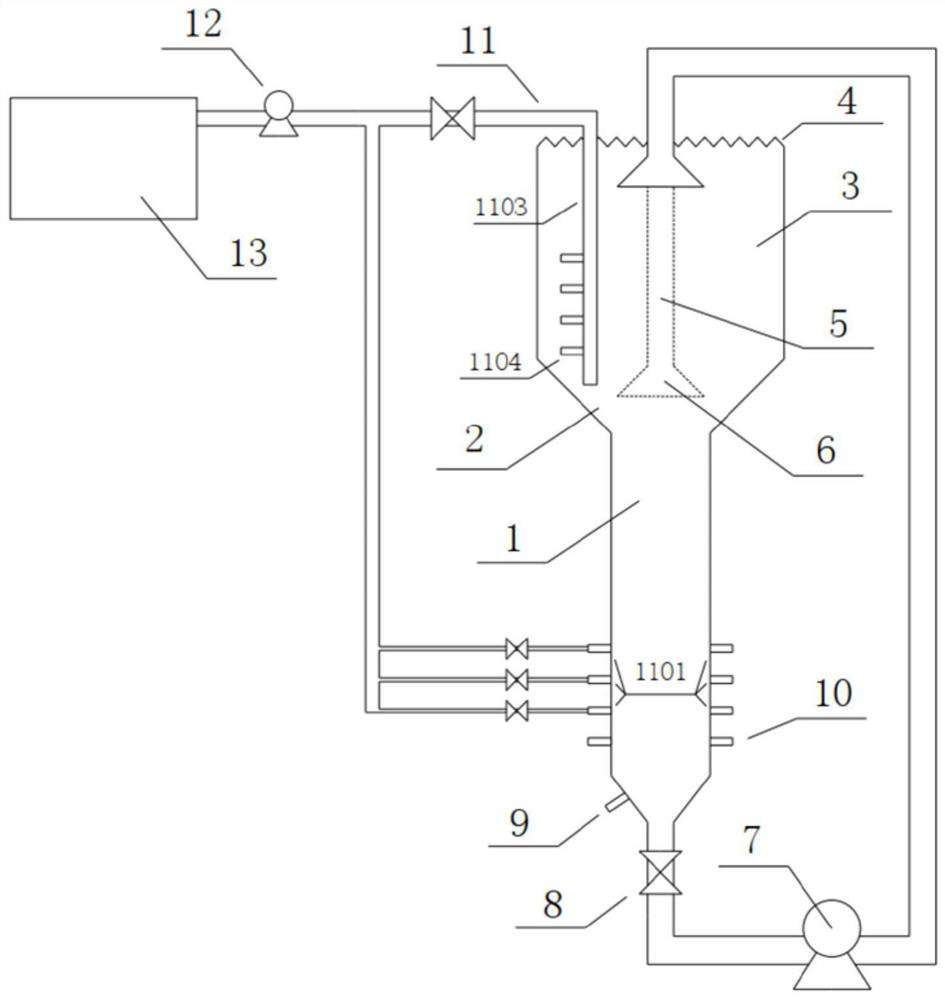

[0056] The present embodiment provides a sewage treatment device capable of controlling the crystallization size of the product, such as figure 2 As shown, the diameter ratio of the sedimentation zone to the fluidization zone is 5:1, and the height ratio of the sedimentation zone, transition zone, and fluidization zone is 1:2:4. Specifically, the design fluidized bed treatment load is 50m 3 / d, the diameter of the fluidized zone is 0.6m, the height is 4.0m, the height of the transition zone is 2.0m, the diameter of the sedimentation zone is 3m, and the height is 1.0m.

[0057] The return pump is an impeller centrifugal pump. The retractable return pipe 5 can adjust the position of the return port in the main body of the fluidized bed, and the position of the return port varies from 1 / 20-1 / 5 below the overflow liquid level at the top of the sedimentation zone to the middle of the transition zone.

[0058] The return port 6 is in the shape of a bell mouth, the angle between th...

Embodiment 3

[0062] This embodiment provides a kind of sewage treatment method, uses the sewage treatment device of embodiment 1, and described method comprises the following steps:

[0063] (1) By adjusting the insertion depth of the reflux pipe in the fluidized bed main body, the reflux port is placed in the middle of the transition zone, and by adjusting the first path of the dosing pipe in the fluidized bed main body Insertion depth, place the top drug injection port in the precipitation area;

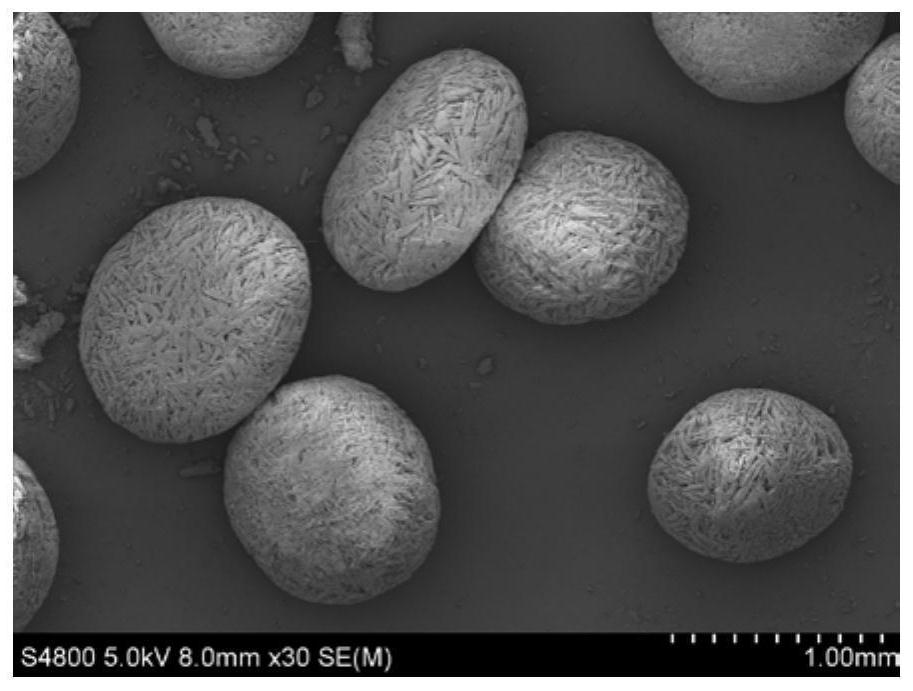

[0064] (2) Input the production wastewater for processing woody activated carbon from the feed inlet to the fluidized bed main body, the phosphate concentration in the wastewater is 1500mg / L, start the reflux pump and the dosing pump, and dosing by the bottom dosing port, Preparation of microcrystals, operating parameters: pH 8.5, rising flow rate in the fluidization zone 0.02m / s, flow rate in the sedimentation zone 0.002m / s; nitrogen source and magnesium source are added through the bottom inj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com