A kind of preparation method of bipolar plate of graphite-based composite material

A technology of composite materials and bipolar plates, applied in fuel cells, final product manufacturing, sustainable manufacturing/processing, etc. Large-scale mass production and other issues to achieve good high thermal stability, good dimensional stability, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

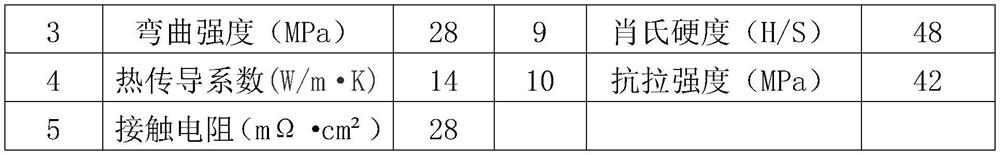

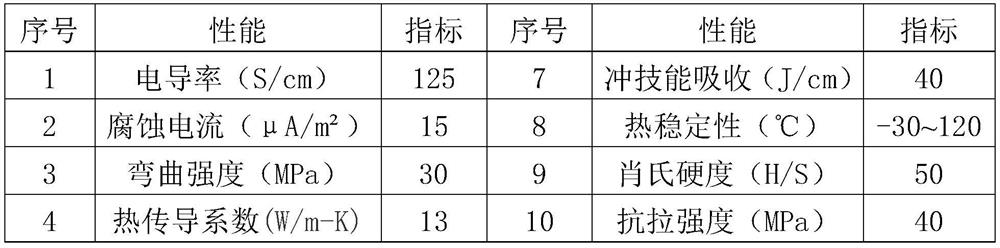

Examples

Embodiment 1

[0027] A method for preparing a graphite-based composite material bipolar plate, comprising the following steps:

[0028] (1) Add carbon nanotubes to the graphite powder, stir and mix under the condition that the ultrasonic power is 300W, the temperature is 60°C, and the rotating speed is 230r / min, so that the two form a homogeneous composite graphite powder, by mass fraction, The composite graphite powder contains 15% carbon nanotubes, the particle size of the graphite powder is greater than 25 meshes, and the particle size of the composite graphite powder is less than 400 meshes;

[0029] (2) Mix the thermosetting resin with the free radical polymerization initiator to obtain mixture A, mix mixture A with a release agent to obtain mixture B, mix mixture B with a shrinkage agent to obtain mixture C, mix mixture C with a tackifier to obtain mixture D, and mix D is dissolved in a solvent to obtain a mixture E containing a thermosetting resin;

[0030] (3) Mix the composite gra...

Embodiment 2

[0043] A method for preparing a graphite-based composite material bipolar plate, comprising the following steps:

[0044] (1) Add carbon nanotubes to the graphite powder, stir and mix under the conditions of ultrasonic power of 250W, temperature of 65°C, and rotating speed of 200r / min, so that the two form a homogeneous composite graphite powder, calculated by mass fraction. The composite graphite powder contains 6% carbon nanotubes, the particle size of the graphite powder is greater than 30 meshes, and the particle size of the composite graphite powder is less than 400 meshes;

[0045] (2) Mix the thermosetting resin with the free radical polymerization initiator to obtain mixture A, mix mixture A with a release agent to obtain mixture B, mix mixture B with a shrinkage agent to obtain mixture C, mix mixture C with a tackifier to obtain mixture D, and mix D is dissolved in a solvent to obtain a mixture E containing a thermosetting resin;

[0046](3) Mix the composite graphit...

Embodiment 3

[0059] A method for preparing a graphite-based composite material bipolar plate, comprising the following steps:

[0060] (1) Add carbon nanotubes to the graphite powder, and stir and mix under the conditions that the ultrasonic power is 150W, the temperature is 45°C, and the rotating speed is 180r / min, so that the two form a homogeneous composite graphite powder, by mass fraction, The composite graphite powder contains 10% carbon nanotubes, the particle size of the graphite powder is greater than 20 meshes, and the particle size of the composite graphite powder is less than 400 meshes;

[0061] (2) Mix the thermosetting resin with the free radical polymerization initiator to obtain mixture A, mix mixture A with a release agent to obtain mixture B, mix mixture B with a shrinkage agent to obtain mixture C, mix mixture C with a tackifier to obtain mixture D, and mix D is dissolved in a solvent to obtain a mixture E containing a thermosetting resin;

[0062] (3) Mix the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com