Method for judging abnormal reasons of solar cell based on PL test

An abnormal cause, solar cell technology, used in semiconductor/solid-state device testing/measurement, circuits, photovoltaic power generation, etc., can solve problems that cannot be quickly confirmed and analyzed, cannot detect roller marks and blanking belt marks, PL The test shows problems such as abnormality, so as to shorten the abnormal processing and recovery time, save the sample preparation time, and reduce the loss of process capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

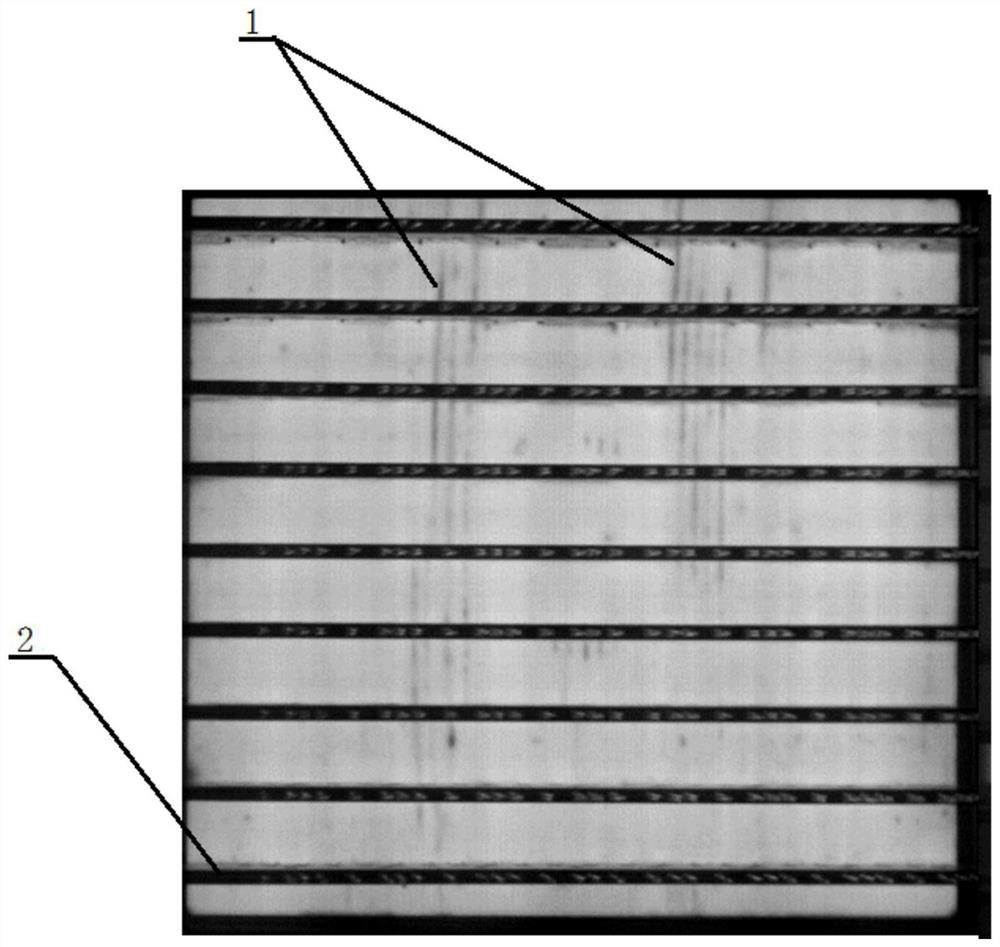

[0038] The present invention provides a method for quickly determining the cause of abnormality of SE-PERC solar cells based on PL test. The method is mainly applicable to the situation where abnormality occurs in the wet etching blanking belt and re-inspection is carried out after repairing the abnormality. Specifically: in the production In the routine process of the workshop, when the EL inspection is performed on the finished solar cell, it is found in the image of the EL inspection that such figure 1 The regular dark striped area perpendicular to the busbar 2 shown in the figure, the engineer determined that the regular dark striped area is the wet etching blanking belt print 1 according to the existing method for judging abnormal parts, so the abnormal machine The wet etching blanking belt of the specified pass is repaired. In order to quickly check whether it can work normally after repair, the engineer can use the method of this application to judge without waiting for ...

Embodiment 2

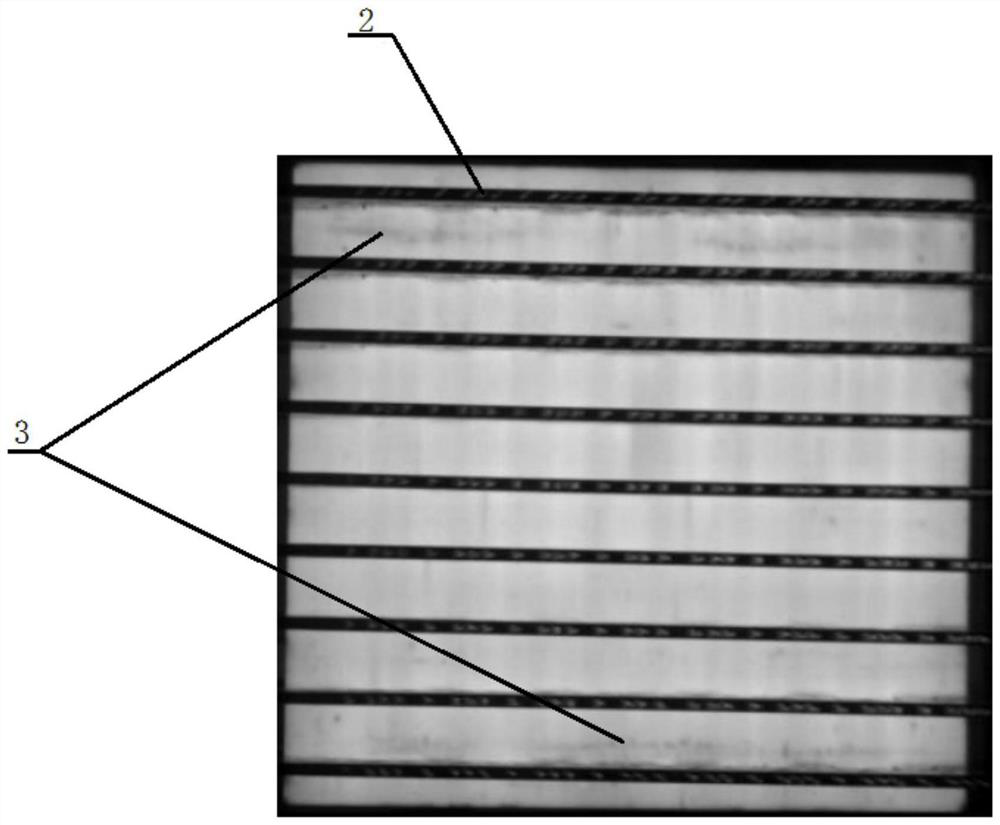

[0046] The present invention provides a method for quickly determining the cause of abnormality of SE-PERC solar cells based on PL test. The method is mainly applicable to the situation where the front roller of the flip windmill is abnormal and the abnormality is repaired, and re-inspection is carried out. Specifically: in the production workshop In the conventional manufacturing process, when the EL inspection is performed on the finished solar cell, it is found in the image of the EL inspection that such image 3 The regular dark strip area parallel to busbar 2 is shown. According to the existing method for judging abnormal parts, the engineer has determined that the regular dark strip area is the front roller print 3 of the flip windmill. Therefore, the abnormal machine is assigned a road In order to quickly recheck whether it can work normally after maintenance, the engineer can use the method of this application to judge, without waiting for a finished cell to be prepared...

Embodiment 3

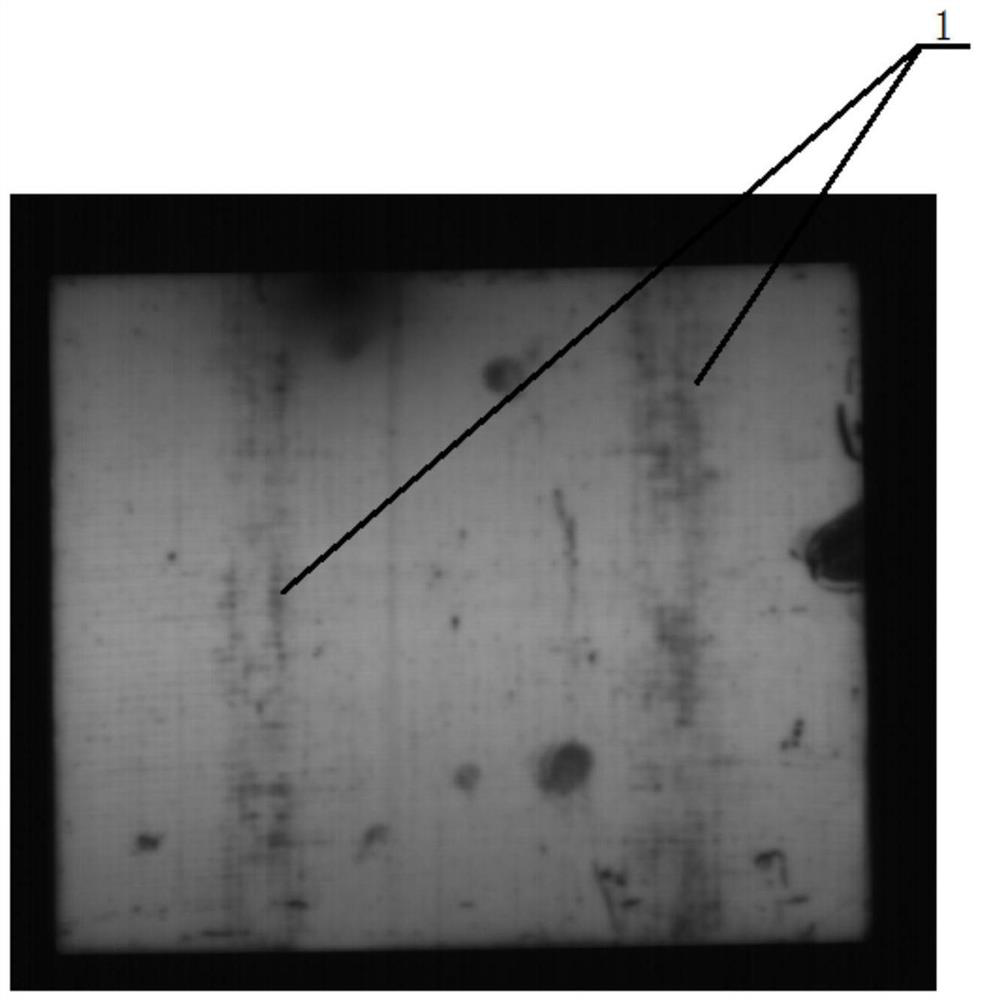

[0054] Of course, the method of the present application is not limited to use after EL detection, and can also be taken directly in the wet etching stage. In this embodiment, the silicon wafer to be tested and the PL detection are sequentially prepared according to the method of rapid determination in Example 2. In the test results of this embodiment, there are two groups of regular dark stripes that are perpendicular to each other. Therefore, it can be concluded that one group must be the front roller print 3 of the flip windmill, and the other group may be the wet etching blanking belt print 1. , it may also be printed on the coating passivation loading and unloading belt. When distinguishing, this embodiment traces the source according to the width and spacing of the wet etching blanking belt and the coating passivation loading and unloading belt, and finally determines another group The imprint is the wet etching blanking belt print 1, and then when inferring the abnormal m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com