Magneto-rheological transmission device extruding bearing bushes based on coil heating induced shape memory alloys

A memory alloy and transmission technology, applied in clutches, fluid clutches, mechanical equipment, etc., can solve the problems of poor reliability and stability, large temperature influence, low transmission efficiency, etc., to reduce energy waste and strengthen magnetorheological effects. , the effect of enhancing transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

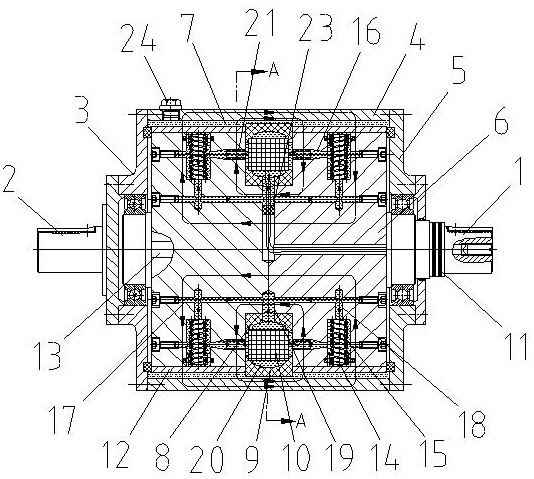

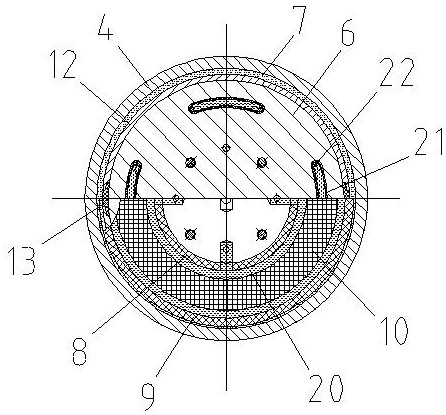

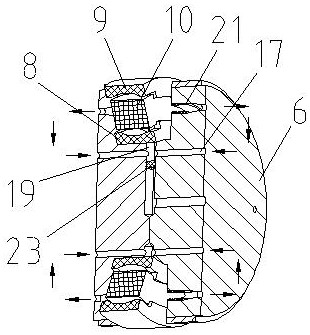

[0028] Example: see Figure 1 to Figure 7 , a magneto-rheological transmission device based on extruded bearings of extruded shape memory alloys induced by coils, including a driving shaft 1 , a driven housing and a driven shaft 2 . The driven housing includes a left end cover 3 , a driven cylinder 4 and a right end cover 5 connected in sequence. The left end of the driving shaft 1 passes through the right end cover 5 and then extends into the driven housing, and is connected with the left end cover 3 and the right end cover 5 through bearings. The part of the driving shaft 1 located in the driven housing is enlarged to form a transmission section 6 , and there is a gap between the transmission section 6 and the inner wall of the driven cylinder 4 , and the gap is filled with magnetorheological fluid 7 . The driven shaft 2 is fixedly connected with the left end cover 3 . During specific implementation, a stuffy cover is provided on the left side of the left end cover 3, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com