Preparation process of polyacrylonitrile fibers and polyacrylonitrile fibers

A technology of polyacrylonitrile fiber and preparation process, which is applied in the direction of fiber treatment, fiber chemical characteristics, single-component synthetic polymer rayon, etc., which can solve the problem of increasing the production cost of spinning machine, complicated and cumbersome spinning process, and reducing production Efficiency and other issues, to achieve the effect of shortening the production process, ensuring quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

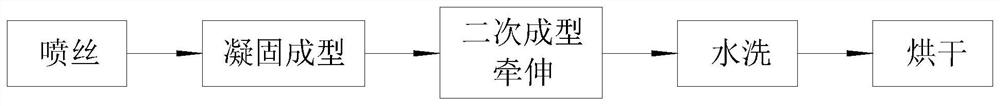

[0064] Such as figure 1 As shown, the present embodiment provides a preparation process for polyacrylonitrile fibers, including:

[0065] Spinning the spinning dope through a spinning device;

[0066] The sprayed spinning dope is shaped by a forming device to obtain a tow;

[0067] The formed tow is washed with water and dried to obtain polyacrylonitrile fibers.

[0068] Wherein, the sprayed spinning dope is solidified and formed in the forming device first, and then secondary forming is performed, and a drafting is completed in the process of secondary forming to obtain the formed tow. The formed tow is no longer drawn in the subsequent washing and drying process.

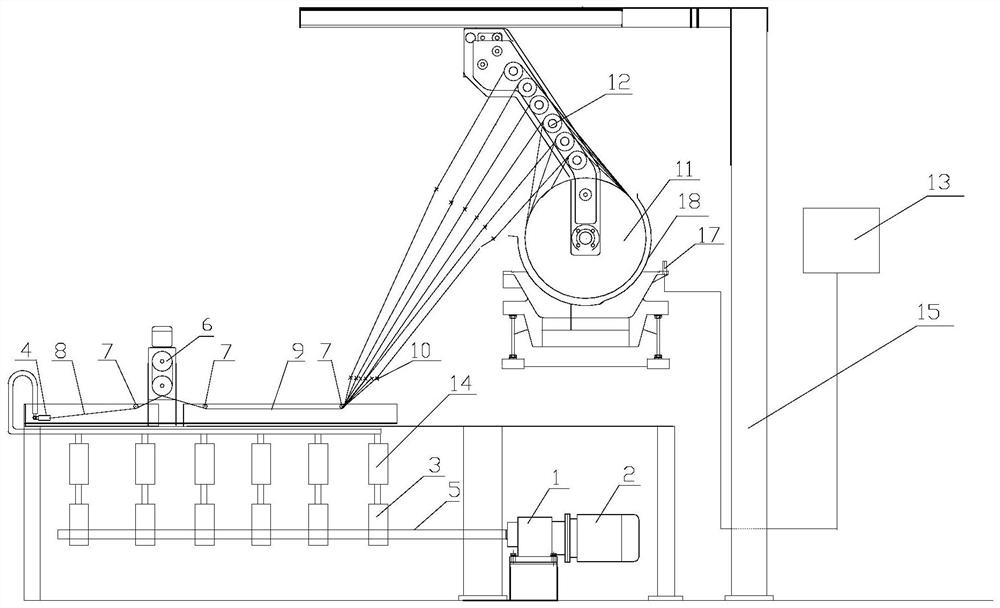

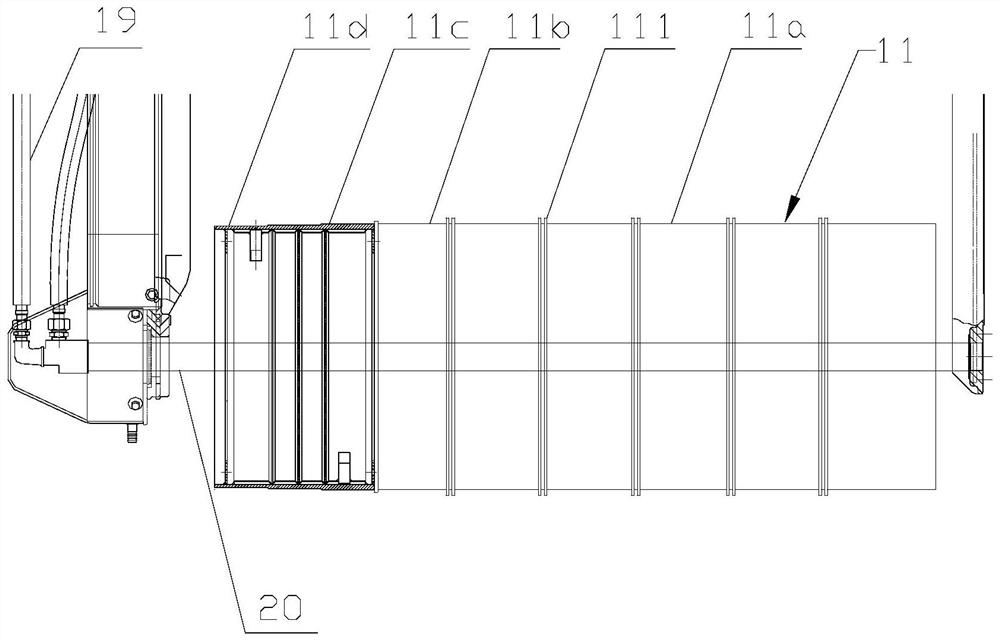

[0069] In order to realize the preparation technology of polyacrylonitrile fiber in the present embodiment, adopt such as Figure 2 to Figure 4 The spinning machine shown carries out the production of polyacrylonitrile fibers. Described spinning machine comprises frame 15, is used for the spinneret device tha...

Embodiment 2

[0133] This embodiment provides a polyacrylonitrile fiber, the breaking strength of the polyacrylonitrile fiber is 2.5-7.0dN.tex.

[0134] The polyacrylonitrile fiber is spinned and formed from the spinning stock solution to obtain tow. During the forming process, the tow is drawn once, and the formed tow is washed with water and dried to obtain polyacrylonitrile fiber.

[0135] In a further solution of this embodiment, the polyacrylonitrile fiber is produced by the preparation process of the polyacrylonitrile fiber described in the first embodiment above.

[0136] Preferably, the fineness of the polyacrylonitrile fiber in this embodiment is 40-320 dtex, and the single-filament fineness is 1-10 dtex.

[0137] More preferably, the polyacrylonitrile fibers are acrylic filaments, and the polyacrylonitrile fibers can be directly used for weaving textile fabrics.

[0138] The polyacrylonitrile fiber of this embodiment has suitable breaking strength and fineness, when the polyacryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com