Preparation process of PVC architectural decoration film

A technology of architectural decoration and preparation technology, which is applied in the field of architectural decoration, can solve the problems of shortened service life and decorative effect, large damage of PVC architectural decorative film, unfavorable building temperature adjustment, etc., so as to improve tear resistance, reduce energy consumption, The effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

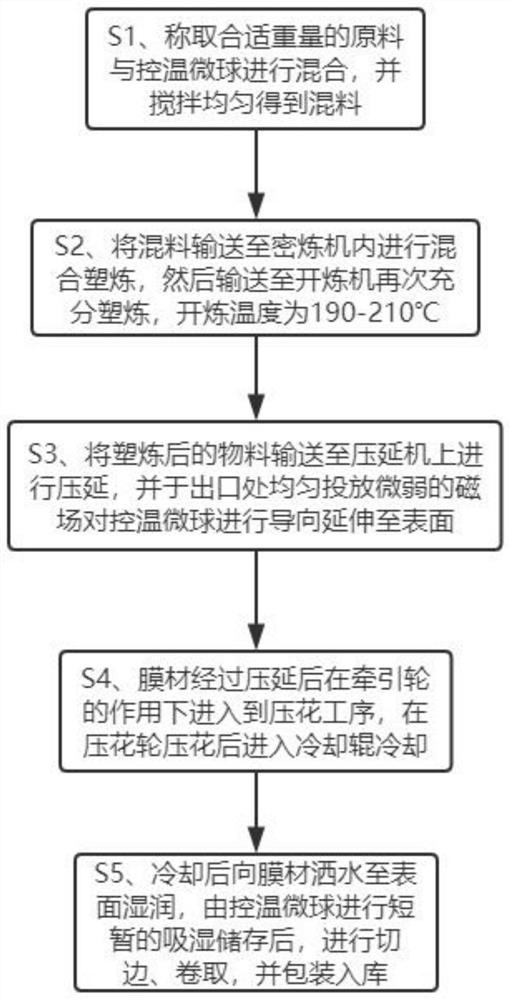

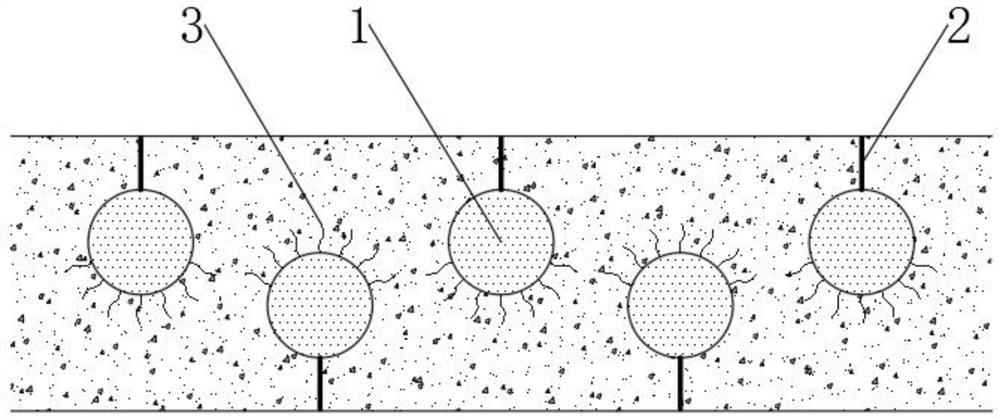

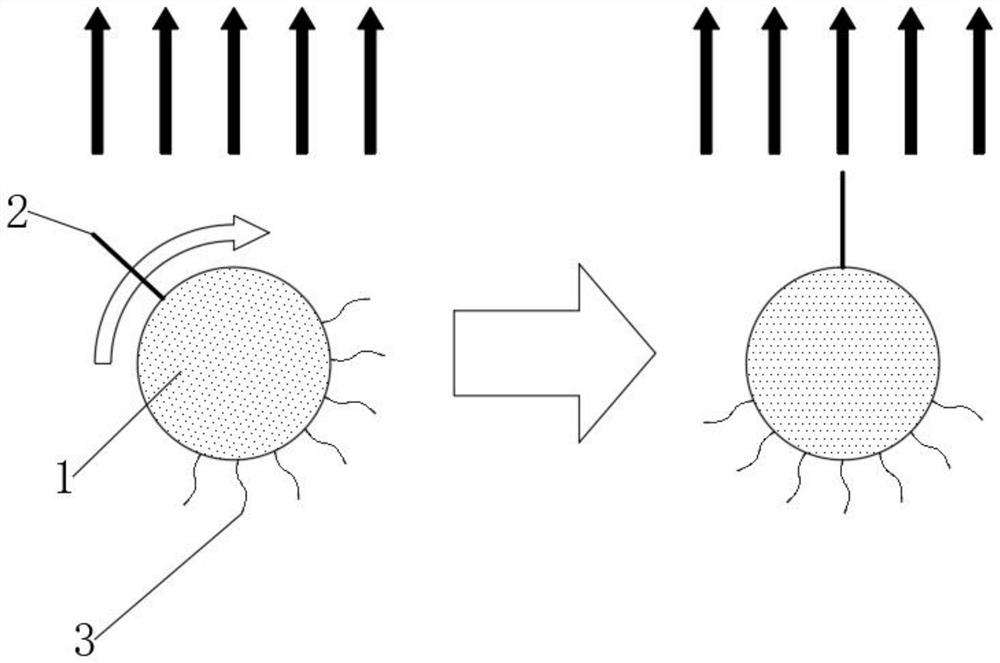

[0042] see Figure 1-3 , a kind of preparation technology of PVC building decoration film, comprises the following steps:

[0043] S1. Weigh an appropriate weight of raw materials and mix them with temperature-controlled microspheres, and stir them evenly to obtain a mixture. The raw materials include the following raw materials in parts by weight: 100 parts of PVC resin, 10 parts of polyurethane elastomer, 40 parts of plasticizer, 10 parts of filler, 1 part of stabilizer, 1 part of lubricant and 2 parts of antioxidant, the mass ratio of raw materials to temperature-controlling microspheres is 1:0.05, and the diameter of temperature-controlling microspheres is smaller than the thickness of PVC architectural decorative film;

[0044] S2. Transport the mixed materials to the internal mixer for mixing and plasticizing, and then transport to the open mill for further plasticizing. The temperature of the kneading is 190°C. After extrusion, use a 100-mesh filter to filter, and then ...

Embodiment 2

[0054] see Figure 1-3 , a kind of preparation technology of PVC building decoration film, comprises the following steps:

[0055] S1. Weigh an appropriate weight of raw materials and mix them with temperature-controlled microspheres, and stir them evenly to obtain a mixture. The raw materials include the following raw materials in parts by weight: 100 parts of PVC resin, 20 parts of polyurethane elastomer, 50 parts of plasticizer, 15 parts of filler, 3 parts of stabilizer, 2 parts of lubricant and 3 parts of antioxidant, the mass ratio of raw materials to temperature-controlling microspheres is 1:0.08, and the diameter of temperature-controlling microspheres is smaller than the thickness of PVC architectural decorative film;

[0056] S2. Transport the mixed materials to the internal mixer for mixing and plasticizing, and then transport to the open mill for further plasticizing. The temperature of the kneading is 200°C. After extrusion, use a 150-mesh filter to filter, and the...

Embodiment 3

[0062] see Figure 1-3 , a kind of preparation technology of PVC building decoration film, comprises the following steps:

[0063] S1. Weigh an appropriate weight of raw materials and mix them with temperature-controlled microspheres, and stir evenly to obtain a mixture. The raw materials include the following raw materials in parts by weight: 100 parts of PVC resin, 30 parts of polyurethane elastomer, 60 parts of plasticizer, 20 parts of filler, 5 parts of stabilizer, 3 parts of lubricant and 4 parts of antioxidant, the mass ratio of raw materials to temperature-controlling microspheres is 1:0.1, and the diameter of temperature-controlling microspheres is smaller than the thickness of PVC architectural decorative film;

[0064] S2. Transport the mixed materials to the internal mixer for mixing and plasticizing, and then transport to the open mill for further plasticizing. The temperature of the kneading is 210°C. After extrusion, use a 200-mesh filter to filter, and then use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com