Heat preservation tunnel for continuously conveying heat pipes and heat preservation control method

A technology of tunnels and heat pipes, which is applied in the heat preservation tunnel and control heat preservation field of continuous transport heat pipes, which can solve the problems of uncontrollable heat loss, seamless pipes that cannot meet performance requirements, and temperature requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

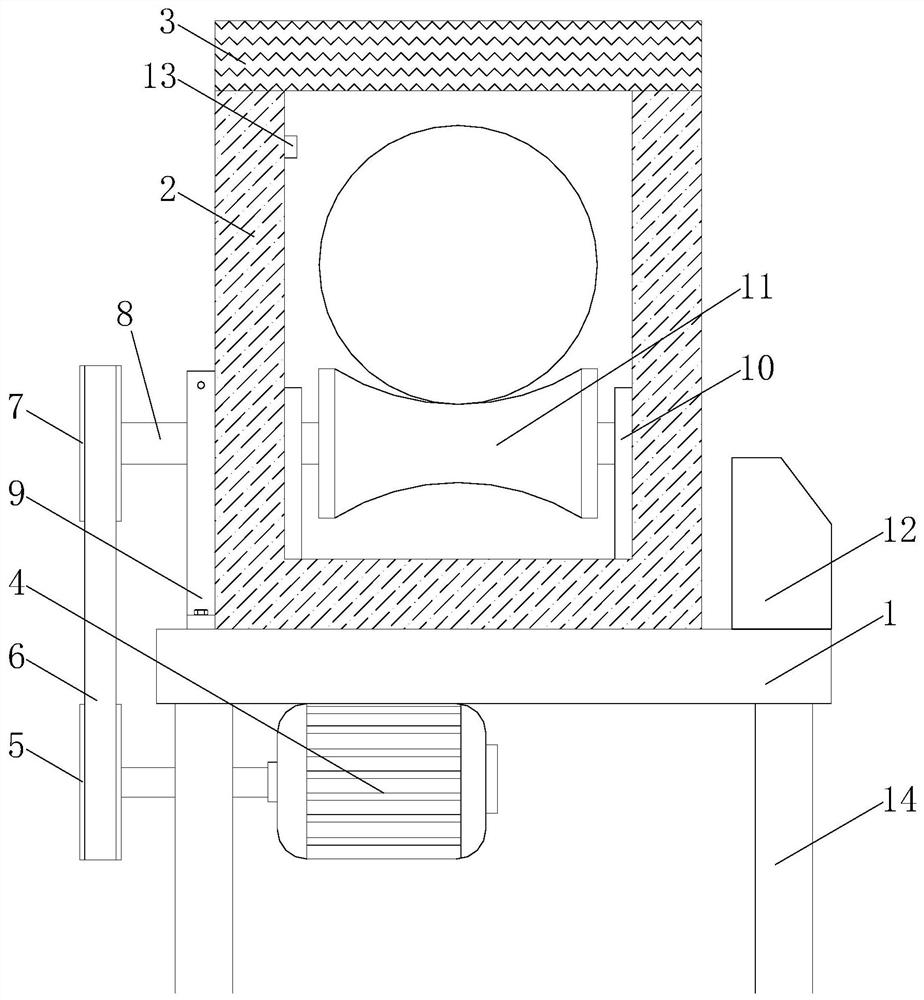

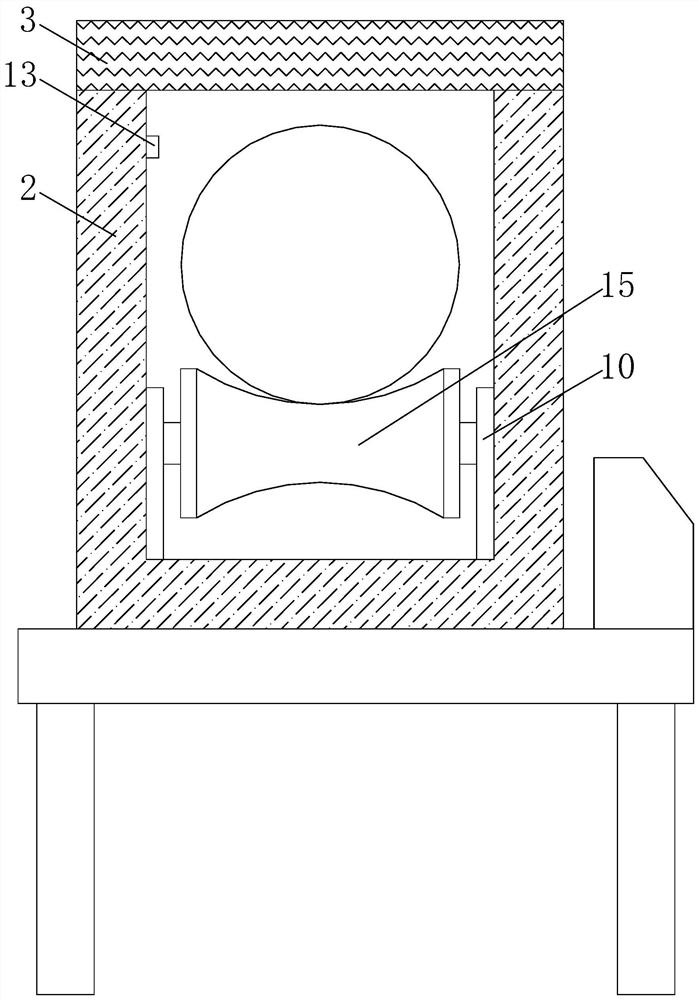

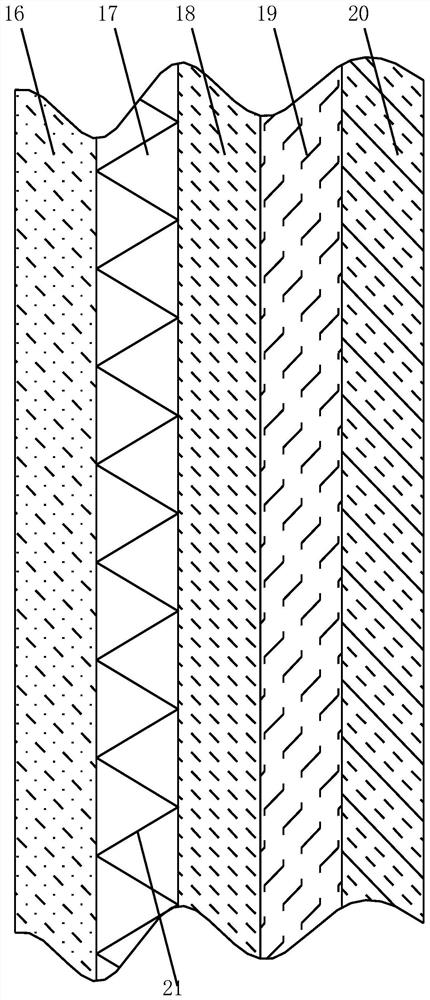

[0030] Such as Figure 1-5 As shown, the present invention provides a kind of technical scheme:

[0031]A thermal insulation tunnel for continuously transporting heat pipes, comprising a base 1, a support frame 14 is fixedly installed on the bottom of the base 1, and an anti-skid mat is fixedly installed on the bottom of the support frame 14, and the thermal insulation tunnel 2 is supported at a required height by the support frame 14, and the base The upper surface of the base 1 is fixedly installed with a thermal insulation tunnel 2, the upper surface of the base 1 is fixedly equipped with an outer support seat 9 located on the left side of the thermal insulation tunnel 2, and the upper surface of the base 1 is fixedly installed with a control panel 12 located on the right side of the thermal insulation tunnel 2, The lower surface of the base 1 is fixedly installed with a drive motor 4, and one side of the thermal insulation tunnel 2 is fixedly installed with a thermocouple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com